381298/C

237

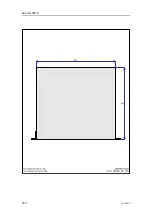

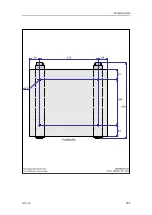

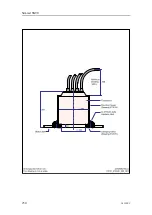

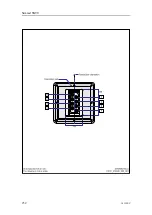

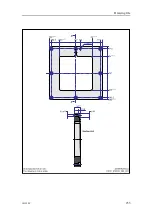

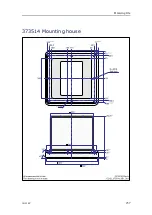

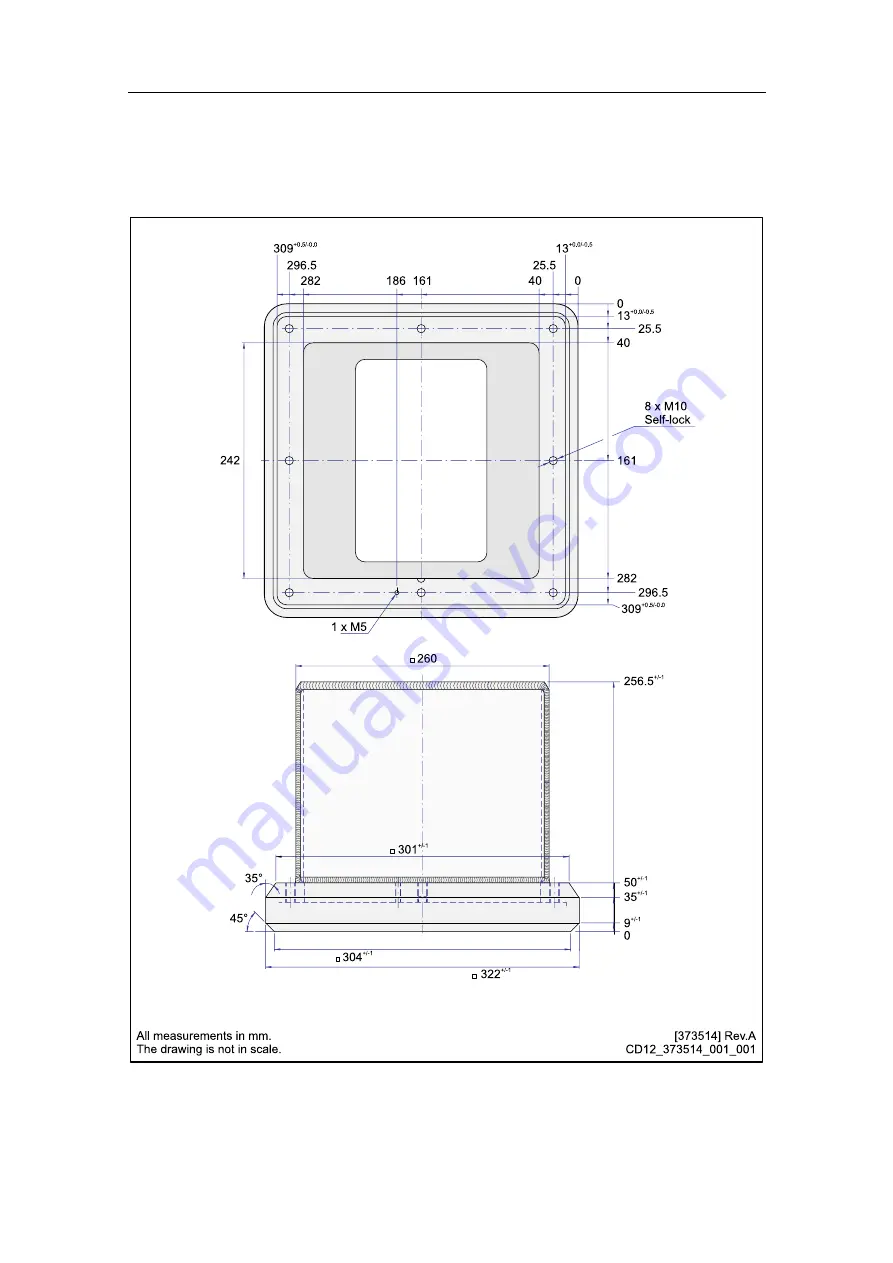

373514 Mounting house

All measurements in mm.

The drawing is not in scale.

[373514] Rev .A

CD12_373514_001_001

186

309

+0.5/-0.0

296.5

282

161

40

0

13

+0.0/-0.5

25.5

40

161

282

1 x M5

242

296.5

309

+0.5/-0.0

8 x M10

Self-lock

256.5

+/-1

50

+/-1

304

+/-1

35

+/-1

322

+/-1

9

+/-1

0

301

+/-1

35°

45°

260

25.5

13

+0.0/-0.5

0

Summary of Contents for Simrad SN90

Page 2: ......

Page 117: ...381298 C 115 Related topics Installation summary page 65 Installing the transducer ...

Page 236: ...234 381298 C 372915 Clamping frame Simrad SN90 ...

Page 295: ......

Page 296: ... 2016Kongsberg Maritime ISBN 978 82 8066 179 1 ...

Page 297: ......