Guide for Raised-Floor Preparation

A raised floor is not required for the

Eserver

pSeries 690 (except in Canada). However, it is

recommended for optimum system cooling and cable management. Raised floor cutouts should be

protected by electrically nonconductive molding, appropriately sized, with edges treated to prevent cable

damage and to prevent casters from rolling into the floor cutouts.

Front-service access is necessary on the

Eserver

pSeries 690 to accommodate a lift tool for the

servicing of large drawers (the managed server, IO drawer, and media subsystems). Front and rear service

access is necessary to accommodate the lift tool for servicing of the optional integrated battery feature

(IBF).

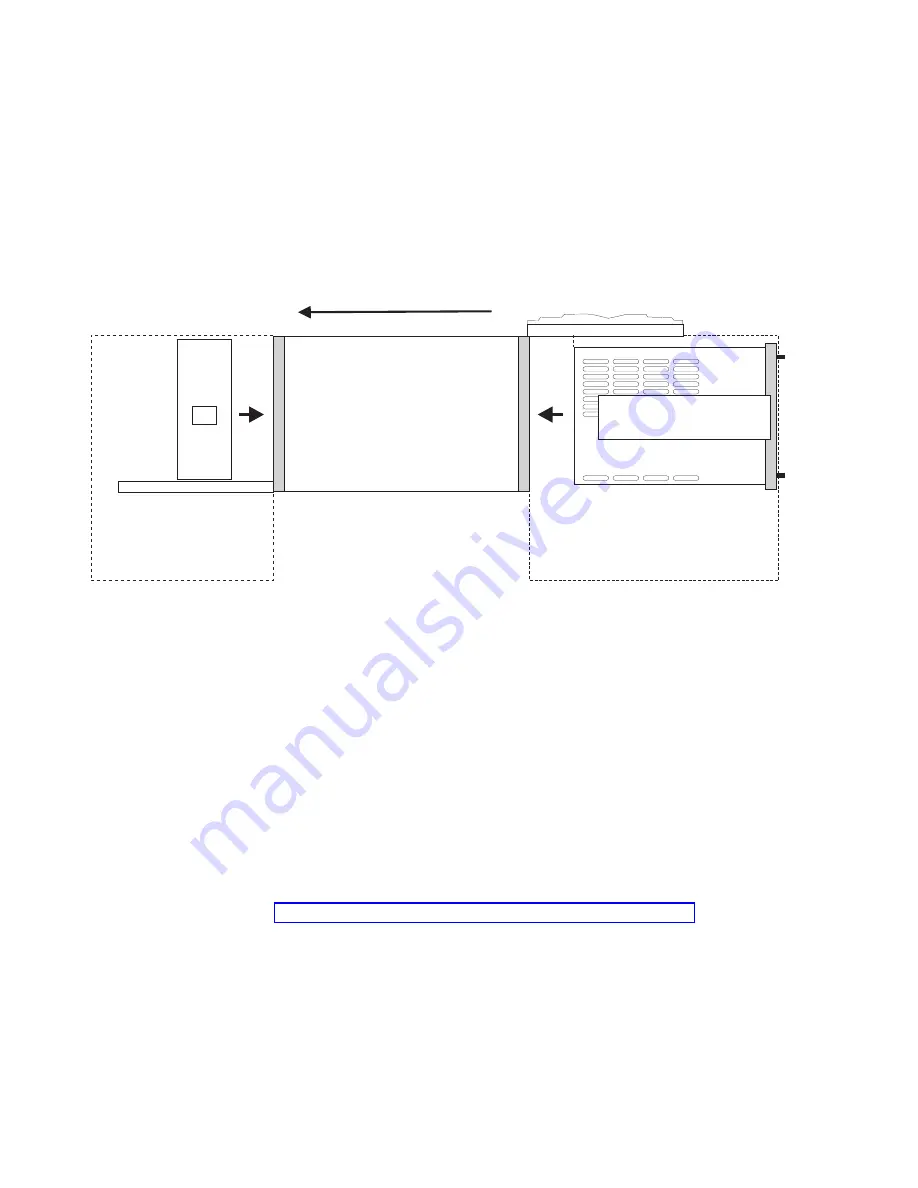

Airflow Direction

Top View

Drawer Subsystems:

Managed Server: ~39” deep

I/O: ~34” deep

!

!

Floor Plan Considerations for Single Units

Lift Tool Service

Clearance

Lift Tool Service

Clearance

IBF

Cutting and Placement of Floor Panels

This section provides recommendations for making the necessary openings in the raised floor for installing

the

Eserver

pSeries 690.

Note:

The following illustration is intended only to show relative positions and accurate dimensions of floor

cutouts. The illustration is not intended to be a machine template and is not drawn to scale.

The x-y alphanumeric grid positions are used to identify relative positions of cutout floor panels that may

be cut in advance.

1. Determine whether the system you will be installing has one or two frames.

2. Measure the panel size of the raised floor.

3. Verify the floor panel size. The floor panel size illustrated is 600 mm (23.6 in.) and 610 mm (24 in.)

panels.

4. Ensure adequate floor space is available to place the frames over the floor panels exactly as shown in

the illustration. Refer to “Considerations for Multiple System Installations” on page 192 for front-to-back

and side-to-side clearances. Use the plan view if necessary. Consider all obstructions above and below

the floor.

5. Identify the panels needed, and list the total quantity of each panel required for the installation.

6. Cut the required quantity of panels. When cutting the panels, you must adjust the size of the cut for

the thickness of the edge molding you are using. The dimensions shown in the illustrations are finished

dimensions. For ease of installation, number each panel as it is cut, as shown in the following

illustrations.

182

Site and Hardware Planning Information

Summary of Contents for 7012 397

Page 1: ...RS 6000 and Eserver pSeries Site and Hardware Planning Information SA38 0508 20...

Page 2: ......

Page 3: ...RS 6000 and Eserver pSeries Site and Hardware Planning Information SA38 0508 20...

Page 11: ...Appendix Notices 385 Index 387 Contents ix...

Page 12: ...x Site and Hardware Planning Information...

Page 16: ...xiv Site and Hardware Planning Information...

Page 18: ...xvi Site and Hardware Planning Information...

Page 26: ...8 Site and Hardware Planning Information...

Page 238: ...220 Site and Hardware Planning Information...

Page 246: ...228 Site and Hardware Planning Information...

Page 284: ...266 Site and Hardware Planning Information...

Page 296: ...278 Site and Hardware Planning Information...

Page 366: ...348 Site and Hardware Planning Information...

Page 372: ...Async Adapter Cable Planning Chart 354 Site and Hardware Planning Information...

Page 377: ...Standard I O Cable Planning Chart Chapter 12 Cable Planning 359...

Page 380: ...Cable Planning Chart Other Adapters 362 Site and Hardware Planning Information...

Page 384: ...366 Site and Hardware Planning Information...

Page 402: ...384 Site and Hardware Planning Information...

Page 404: ...386 Site and Hardware Planning Information...

Page 413: ......

Page 414: ...Printed in USA SA38 0508 20...

Page 415: ...Spine information RS 6000 and Eserver pSeries Site and Hardware Planning Information...