Inspection, Maintenance and Adjustment

4-99

DX380LC-7

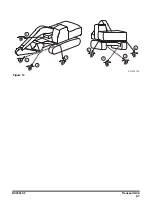

4.

A track that is properly adjusted may have a different sag

according to the track options. Contact your dealer for

information.

5.

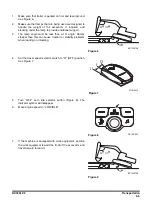

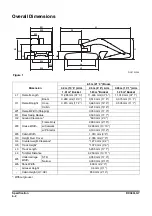

The track tension can be adjusted with the grease fitting

valve (1, Figure 138) and handle screws (2, Figure 138) in

the center of each side frame. Filling the grease fittings

with grease increases the length of the adjustable

cylinders. The longer the adjustable cylinders become, the

more pressure builds in the tension springs which expand

beyond the track idlers.

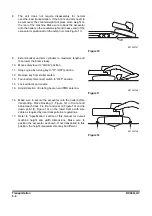

6.

If the tracks and adjustment devices expand to the point

that there is a lack of deflection or space between parts,

turn the handle screw clockwise once or twice to drain

some of the grease. Once the track tension is suitable,

tighten the handle screw in the counterclockwise direction.

•

Grease fitting valve tightening torque: 68.6 ±9.8 N.m

(7 kg ±1 kg.m, 5.2 ±0.7 ft lb)

•

Check the tension again after rotating the track 3 ~ 4

times.

NOTE:

After draining, failure to turn the handle screw

counterclockwise will allow the grease to keep

draining.

Also, turning it too far counterclockwise may

cause damage to the stopper of the screw.

Turn the handle screw by no more than one or

two turns.

Terrain Type

Distance "A"

Normal

380 ~ 410 mm

(15.0 ~ 16.1 in)

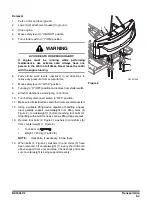

WARNING

AVOID DEATH OR SERIOUS INJURY

The track adjusting mechanism is under very

high-pressure. NEVER release grease pressure too

fast. The track tension grease valve should never be

loosened more than one (1) complete turn from the

fully tightened down position. Bleed off grease

pressure slowly. Keep your body away from the valve

always. Always wear eye and face protection when

adjusting track tension.

DS1901245

1

2

Figure 138