DX380LC-7

Operation

3-68

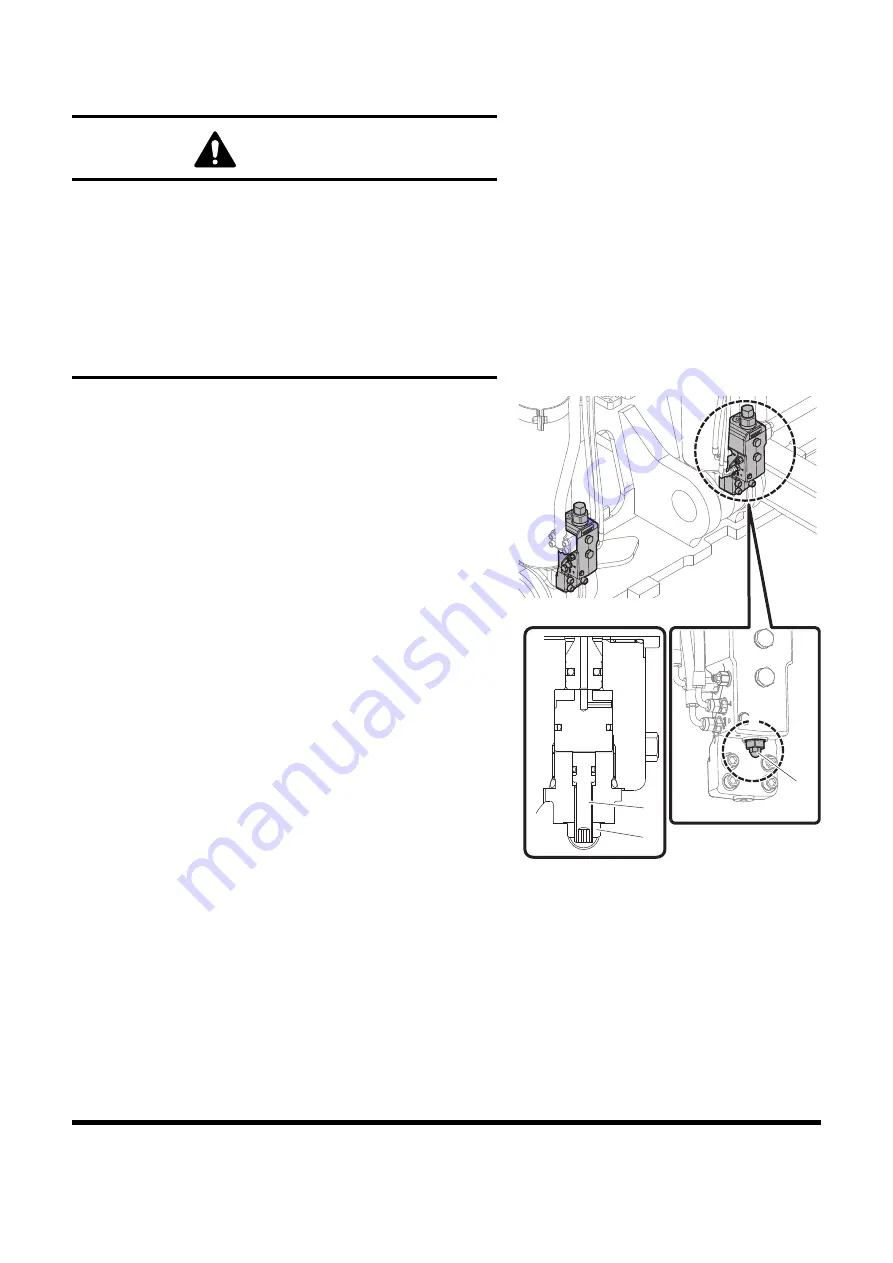

Machine with a Boom Lock Valve

When you must manually lower the boom if the engine has

stopped and cannot be started, or the hydraulic system is

disabled, the operator can still lower the boom, using the

following procedure, when machine is equipped with a boom

lock valve.

1.

Relieve the pressure in the hydraulic system before

manually lowering the boom.

A.

Turn starter switch to "I" (ON) position.

B.

Move the safety lever to "UNLOCKED" position.

C.

Move the joysticks and travel levers/pedals forward

and backward to relieve accumulator pressure.

D.

Turn key to "O" (OFF) position and remove from

starter switch.

2.

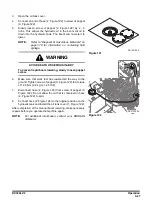

Loosen locknut (1, Figure 123) of the lock valve.

3.

Slowly turn check valve (2, Figure 123) clockwise until

check valve stops. The boom will lower to the ground.

4.

Make sure that front attachment has been completely

lowered onto the ground. Tighten check valve (2, Figure

123).

5.

Tighten locknut (1, Figure 123) to a torque of 39.2 N.m

(4 kg.m, 28.9 Ib ft).

After completion of the manual boom lowering, make necessary

repairs before you operate the machine again.

NOTE:

For additional information, contact your DOOSAN

dealer.

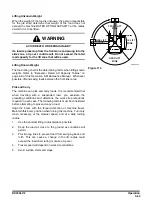

WARNING

AVOID DEATH OR SERIOUS INJURY

Boom weight can cause cylinder oil pressure to reach relief

pressure of the boom lowering control device when the

boom is supported by one cylinder. Boom can lower

suddenly, causing death or serious injury.

To avoid death or serious injury, be sure no one is under or

near the work tool before manually lowering the boom.

Keep all personnel and bystanders away from the boom

area when lowering the boom with the engine stopped.

DS1901507

1, 2

A

Detail

A

1

2

Figure 123