3-89

DX380LC-7

Troubleshooting

Operational Malfunctions

The operator/operating personnel must perform visual fill level

control of the lubricant reservoir at regular intervals. The control

intervals depend on the amount of lubricant required and the

pump's run time. The operator/operating personnel must

therefore determine the intervals on their own based on the

specific conditions of usage.

If the reservoir has been emptied, the entire system must be

ventilated after refilling (see assembly instructions).

All fault notifications are displayed by the LEDs

as a

centralized fault notification. When a fault notification is issued,

the control unit stops the normal operational sequence and the

fault that has occurred is saved and displayed.

The cause of the fault can be read on the display. This greatly

simplifies failure diagnostics, though it requires system

monitoring.

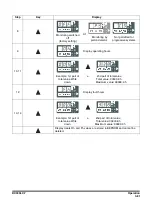

Display Faults

•

Start the display mode with one of the two keys

•

Press the

key until you reach the fault notification (see

the following table)

Display

Explanation

Fault Cycle Switch: No signal from piston detector during pump cycle

(See "Pump Display Mode" on page 3-80.)

Fault Pressure Switch: No signal from pressure switch during pump cycle.

(Not applied to DOOSAN auto grease system)

Fault Low Level: The level in the reservoir has fallen below the minimum fill level.

The further operational sequence has been stopped.