MCO 305 Design Guide

__ Functions and Examples __

42

MG.33.L4.02 – VLT

®

is a registered Danfoss trademark

How to Edit a curve for the Slave Synchronization

1. Set the FC 300 with the required parameters and save these parameters with

Parameters

o

Save to file

with the extension “CNF”.

2. This CNF file must be open in the

CAM-Editor

.

3. Determine the gearing factor of the master in MU units.

Gearing factor = 5/1

Encoder resolution (Incremental encoder) = 500

One revolution of the roller is 360 degrees. We are going to work with a resolution of 1/10 degrees.

This means that we are dividing one revolution of the roller into 3600 work units:

Scaling factor = 3600

MU

1

qc

Factor

Scaling

4

Resolution

Encoder

Factor

Gearing

Enter these whole number values in the index card

o

Synchronization:

Par.

33-10

Syncfactor Master

=

25

Par.

33-11

Syncfactor Slave

=

9

4. Enter the gearing factor of the slave in UU units:

The input should be possible in 1/10 mm resolution.

The drive is connected with the conveyor belt by means of a gearing of 25:11; i.e. the motor makes 25,

the drive pulley 11 revolutions.

Gearing factor = 25/11

Incremental encoder directly on the master drive; encoder resolution = 4096

The drive pulley has 20 teeth/revolution, 2 teeth correspond to 10 mm, thus 1 revolution corresponds

to = 100 mm conveyor belt feed or 1000/10 mm.

Thus, the scaling factor is 1000

UU

1

qc

Factor

Scaling

4

Resolution

Encoder

Factor

Gearing

Enter these values in the index card

o

Encoder

:

Par.

32-12

User Unit Numerator

=

2048

Par.

32-11

User Unit Denominator

=

55

5. Determine a whole number factor for the intervals in the index card

o

Curve Data

so that the Fix points

are on the interpolation points.

A complete cycle length of the master is 360 degrees; this corresponds to 3600 MU.

For a master cycle length of 3600, the

o

Number of Intervals

= 36 produces a reasonable interval time

of 27.7 ms. Set these two values using the “Set” button in the

Curve Data

index card.

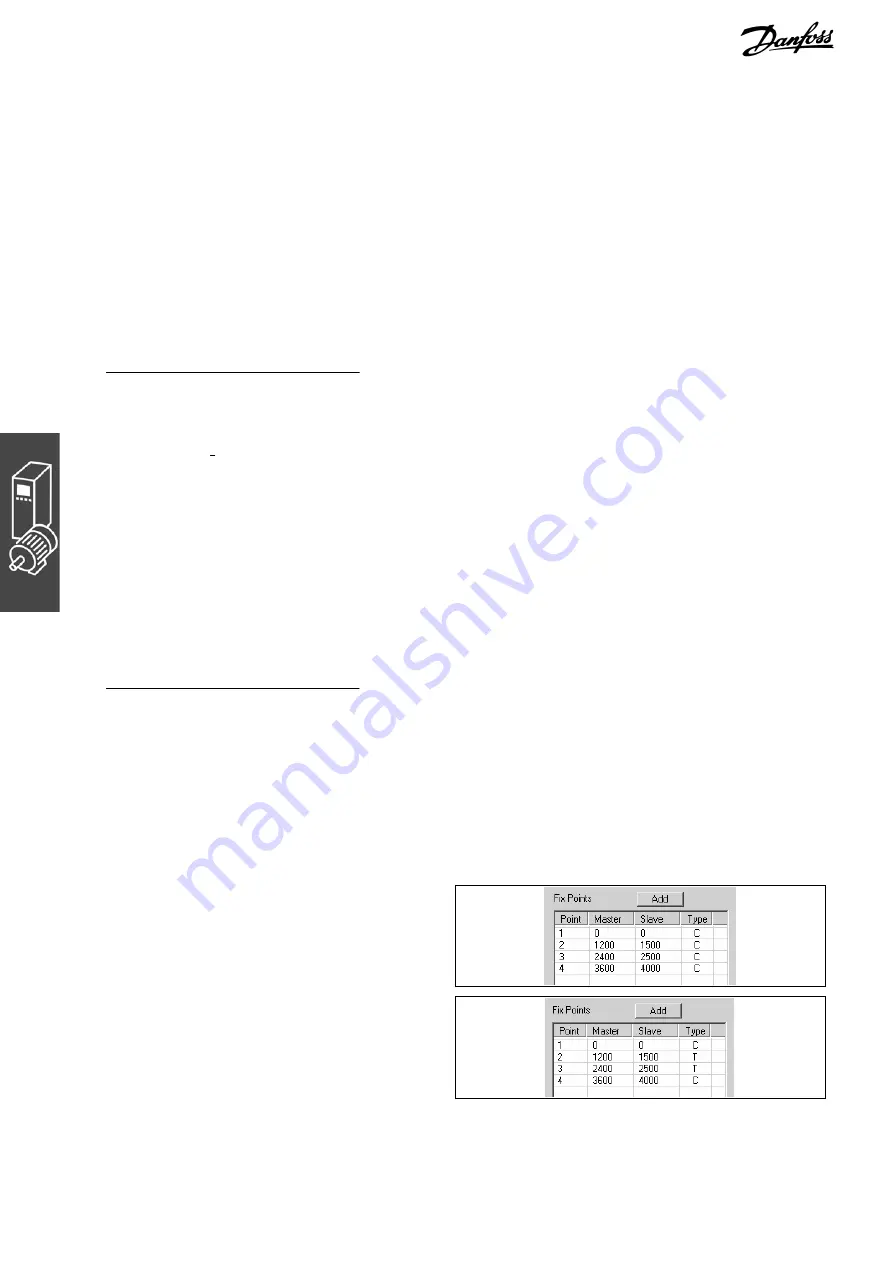

6. Define

o

Fix points

for the roller (slave) and

the conveyor belt (master). The function

o

Snap on Grid

should be activated.

7. Master and slave must run synchronously with

the same velocity between the master posi-

tions 1200 to 2400. For this, you need to have

a straight line that is determined with two tan-

gent points. Double-click in the column

o

Type

for the fixpoint at position 2400.

Summary of Contents for MCO 305

Page 4: ......