MCO 305 Design Guide

__ Functions and Examples __

MG.33.L4.02 – VLT

®

is a registered Danfoss trademark

39

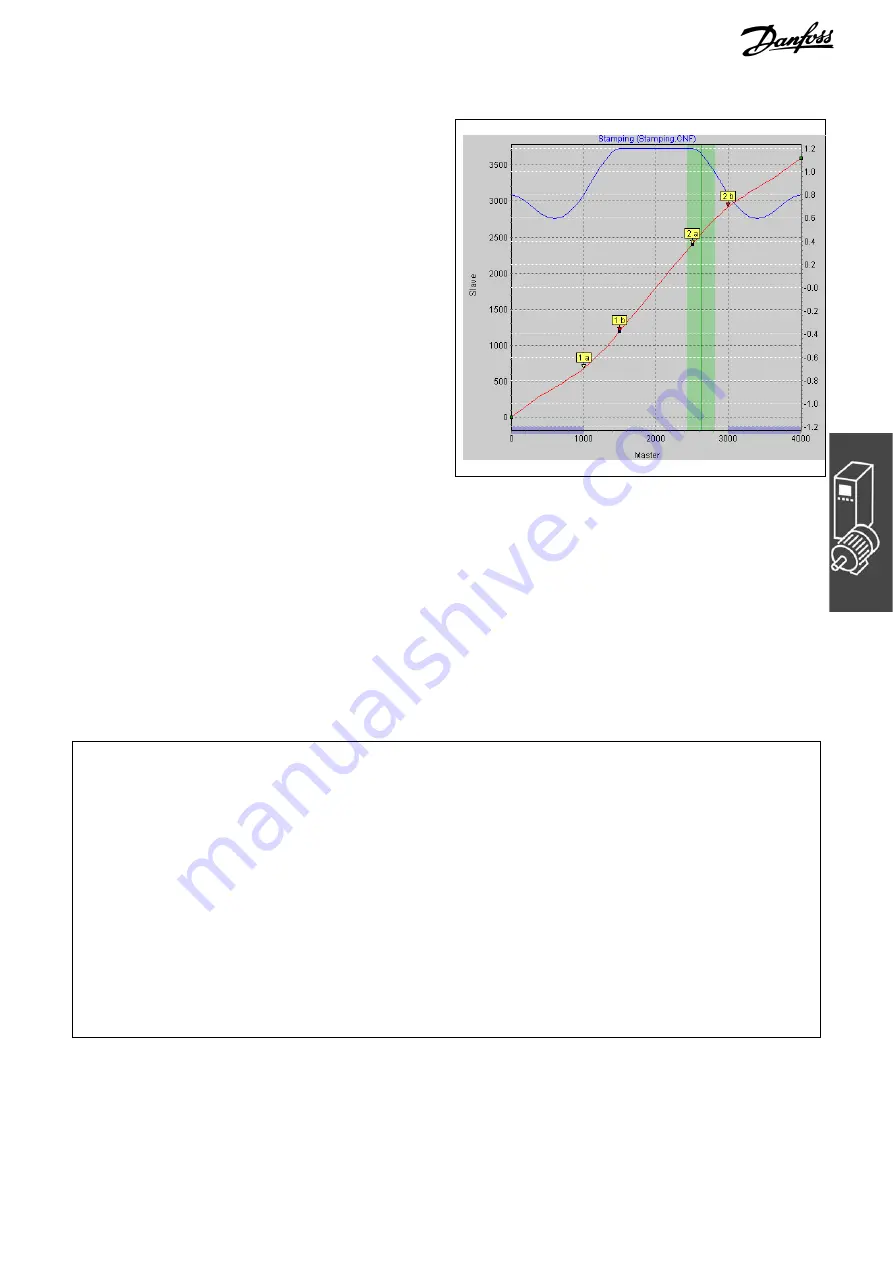

13. Take a look at the curve profile in order to

determine when the correction of the synchro-

nization may begin at the earliest and when it

must be finished. The vertical green line

indicates the master position where the marker

is recognized, the light green area shows the

tolerance window for the appearance of the

master marker.

At the earliest, the correction may begin when

the printing of a box has been completed,

since any change of velocity during the

printing process would damage the box. The

correction must be finished completely when

the next cardboard box reaches the processing

point. In this example, the master positions at

the end and beginning of a box are quite

suitable:

Correction Start

= 3000

Correction End

= 1000

Enter the values in the index card

o

Curve Data

; the depiction of the area is shaded in blue in the

curve profile.

14. Verify whether the velocity and acceleration of the slave remain within the limit. For this purpose, you

must activate the illustration of the

o

;

Velocity

and of the

o

;

Vel.-Limit

and then the illustration of

the

o

;

Acceleration

and of the

o

;

Acc.-Limit.

15. Click the “Save CNF As” button to save the CNF file, for example “marker”.

16. Load the CNF file with the modified parameters and the – automatically generated – curve arrays into

the FC 300 by means of

Parameters

o

Restore from file.

Program Example: Synchronization with Marker

Since the curve is stored internally as an array, the DIM instruction must appear first in your program:

/******** Printing of Cardboard Boxes with Marker Correction (Synchronization with Marker) ******/

DIM marker[112]

// Number of elements from the title bar of the CAM-Editor

HOME

// Slave axis performs a home run (switch for zero position on top)

// Afterwards, the slave will be in the zero position (0 degrees)

// (Omitted if an absolute encoder is used)

SETCURVE marker

// Set stamp curve with marker

dist = GET SYNCMPULSM

// Distance to sensor

DEFMCPOS (1000-dist)

// This is the location that corresponds to the sensor signal

SET SYNCMSTART 2000

// Counting of the master pulse does not begin

// until the next edge comes from the sensor

SYNCCMM 0

// Synchronize in CAM-Mode until motor stop

SYNCCSTART 1

// Engage roller with start point pair 1

// Synchronous operation

WAITI 4 ON

// Wait for input signal when conveyor belt is being switched off

SYNCCSTOP 2 0

// Disengage roller with stop point pair 1 and stop at position 0 degrees

Summary of Contents for MCO 305

Page 4: ......