MCO 305 Design Guide

__ Software Reference __

MG.33.L4.02 – VLT

®

is a registered Danfoss trademark

155

SYNCCMM

Summary

Synchronization in CAM-Mode with master marker correction

Syntax

SYNCCMM num

Parameter

num =

number of curves to be processed;

0 = the drive remains in CAM-Mode until another mode is started with

commands such as MOTOR STOP, CSTART, POSA, etc.

Description

Like SYNCC, the command SYNCCMM brings about synchronization in CAM-Mode,

but beyond that it also performs a marker correction (only if the master moves

forward).

In order to save the distance between sensor and processing point, the par. 33-17

Master Marker Distance

is used. It allows the correction of the marker position

without changing the curve. Also, larger sensor distances than the actual curve

length are possible. In this case, a FIFO is used for the marker correction (see

example).

The marker can be the zero pulse of the encoder or an external 24 V signal.

NB!:

SYNCCMM does not start the slave drive nor does it interrupt on-going motions

(e.g. CVEL), only SYNCCSTART does.

NB!:

The drive remains in CAM-Mode until 'num' curves have been processed

successfully.

If the synchronization (after 'num' curves) is being closed normally, the start stop

point pair 2 will be used – if no SYNCCSTOP with a corresponding point pair is

defined – in order to stop the drive. It will then come to a stop at the position

slavepos

(see parameters).

Command Group

CAM

Cross Index

par. 33-17

Master Marker Distance

Syntax Example

SETCURVE curve

SYNCCMM 1

// Synchronize 1 x in CAM mode with marker correction

Sample

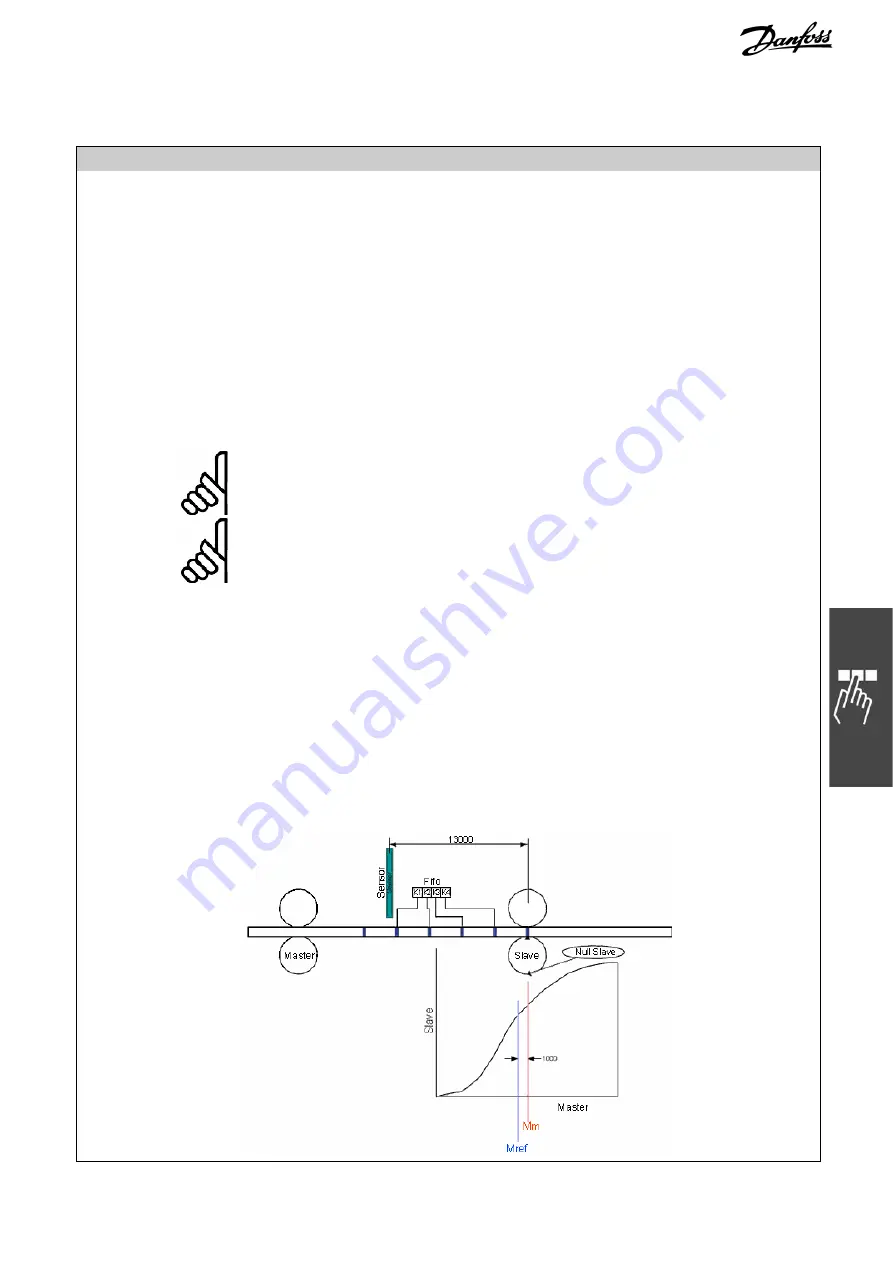

If for example curve length is 3000 and distance of sensor to working point is

13000, we will have a FIFO with 4 Register and an offset of 1000 which has to be

concerned. See the following diagram

Summary of Contents for MCO 305

Page 4: ......