Chapter 2

2-32

F-2-129

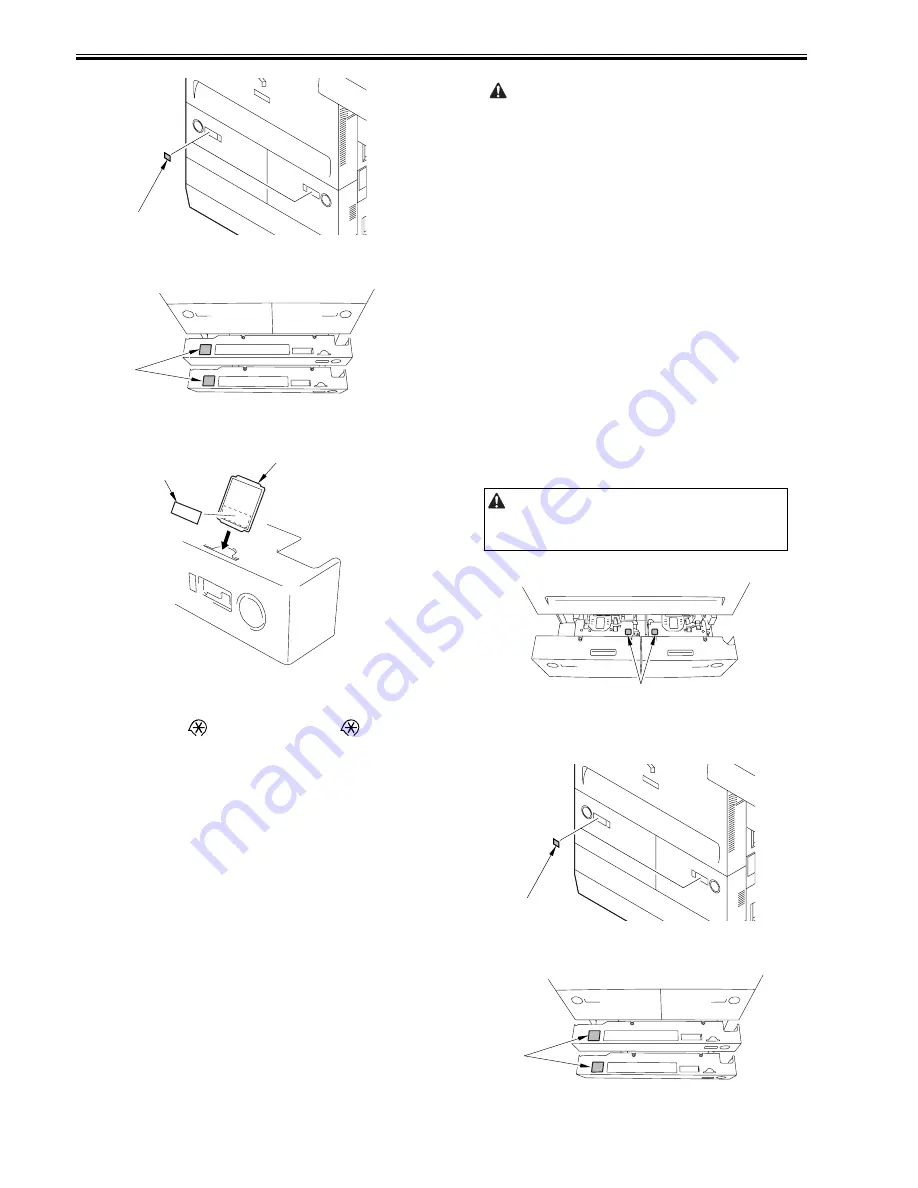

6) Press the release button of the cassette 3/4, and slide out the cassette.

7) Attach the 3-hole paper placement label [1].

F-2-130

8) Affix the corresponding cassette size label [1] onto the paper size plate [2]

of the cassette. Set the paper size plate in the cassette cover.

F-2-131

9) Close the deck/cassette.

10) To ensure stable reproduction of images, generate 2 solid black prints

(A3) as follows:

11) Start service mode. (

'2' and '8' at the same time >

)

12) Make the following selections: COPIER > TEST > PG > PG-PICK.

13) Select the source of paper containing A3 paper, and press the OK key.

('3' for cassette 3; '4' for cassette 4)

14) Press reset once.

15) Make the following selections: COPIER > TEST > PG > TYPE.

16) Type in '7', and press the OK key.

('7' for solid black; PG-TYPE7)

17) Press the Start key to generate a single solid black (A3) print. Check the

output, and wait for about 5 sec. Then, press the Start key to generate an-

other print.

18) When done, press the Reset key twice to end service mode.

19) Place the test sheet on the copyboard, and check the copy image.

Check to be sure that the pickup operation for all sources of paper is

normal (by making 3 test copies each from decks and cassettes).

- check to be sure that there is no abnormal noise.

- check to see that images at all default magnifications are normal.

- check to see that as many copies as specified are made normally.

- if there is a difference in density between left and right, correct it by

adjusting the height of the primary charging wire at the front or the

rear.

- Check to see that copying operation is normal.

horizontal registration standard (margin at image left): 2.5 +/-1.5 mm

lead edge registration standard (margin at image lead edge): 4.0 +1.5/-1.0

mm

If not as indicated, make adjustments by referring to the instructions

under "Adjusting the Horizontal Registration" and "Adjusting the Lead

Edge Registration."

20) Make double-sided copies to check the machine operation.

21) Make standard settings in additional functions and service mode to suit

the needs of the user.

22) Press the Reset key twice to end service mode.

23) Clean up the area around the machine.

24) Move the machine to its final place, and fix it in place using the adjusters.

25) If you are installing accessories, do so according to their respective In-

stallation Procedures.

26) Fill out the service sheet.

2.2.20 Attaching the Labels, Placing Paper, and Checking

Images and Operation

0012-2062

iR7095P

1) Check with the user to find out the size of paper that will be used.

2) Press the release button of the front deck (right, left), and slide out the

deck.

3) Attach the 3-hole paper placement label [1].

F-2-132

4) Put paper in the front deck (right/left).

5) Close the front deck (right/left). Affix the corresponding cassette size la-

bel [1] onto the paper size plate of the each deck.

F-2-133

6) Press the release button of the cassette 3/4, and slide out the cassette.

7) Attach the 3-hole paper placement label [1].

F-2-134

8) Affix the corresponding cassette size label [1] onto the paper size plate [2]

[1]

[1]

[1]

[2]

At times, the first 10 copies or so may show soiled images because of toner

dropping from the drum separation claw. The symptom should disappear as

additional copies are made.

MEMO:

For the Card Reader-D1, see "Card Reader-D1 Installation Procedure."

If you are changing the size of the front deck (right, left), refer to the

instructions under "Switching Over the Front Deck (right/left) Paper Size."

[1]

[1]

[1]

Summary of Contents for iR7086

Page 1: ...Sep 7 2007 Service Manual iR7105 7095 7086 Series...

Page 2: ......

Page 6: ......

Page 26: ...Contents...

Page 27: ...Chapter 1 Introduction...

Page 28: ......

Page 30: ......

Page 32: ...Chapter 1 1 2 Not all products are necessarily available in all sales areas...

Page 55: ...Chapter 2 Installation...

Page 56: ......

Page 150: ......

Page 151: ...Chapter 3 Basic Operation...

Page 152: ......

Page 154: ......

Page 159: ...Chapter 4 Main Controller...

Page 160: ......

Page 162: ......

Page 183: ...Chapter 5 Original Exposure System...

Page 184: ......

Page 228: ......

Page 229: ...Chapter 6 Laser Exposure...

Page 230: ......

Page 232: ......

Page 238: ...Chapter 6 6 6 F 6 7 1 Laser light 2 Laser shutter 1 2 1 2 2 1...

Page 240: ......

Page 241: ...Chapter 7 Image Formation...

Page 242: ......

Page 246: ......

Page 294: ......

Page 295: ...Chapter 8 Pickup Feeding System...

Page 296: ......

Page 300: ......

Page 353: ...Chapter 9 Fixing System...

Page 354: ......

Page 378: ......

Page 379: ...Chapter 10 External and Controls...

Page 380: ......

Page 384: ......

Page 394: ...Chapter 10 10 10 F 10 7...

Page 417: ...Chapter 11 MEAP...

Page 418: ......

Page 420: ......

Page 466: ......

Page 467: ...Chapter 12 RDS...

Page 468: ......

Page 470: ......

Page 479: ...Chapter 13 Maintenance and Inspection...

Page 480: ......

Page 482: ......

Page 496: ......

Page 497: ...Chapter 14 Standards and Adjustments...

Page 498: ......

Page 526: ......

Page 527: ...Chapter 15 Correcting Faulty Images...

Page 528: ......

Page 530: ......

Page 560: ......

Page 561: ...Chapter 16 Self Diagnosis...

Page 562: ......

Page 564: ......

Page 584: ......

Page 585: ...Chapter 17 Service Mode...

Page 586: ......

Page 588: ...Contents 17 8 1 1 COPIER Items 17 94...

Page 688: ......

Page 689: ...Chapter 18 Upgrading...

Page 690: ......

Page 692: ......

Page 696: ...Chapter 18 18 4...

Page 713: ...Chapter 18 18 22 formatting and download the system software once again...

Page 726: ...Chapter 19 Service Tools...

Page 727: ......

Page 729: ......

Page 733: ......

Page 734: ...Sep 7 2007...

Page 735: ......