Chapter 14

14-21

F-14-46

9) Fit the door switch actuator into the door switch assembly.

10) Turn on the power switch.

Once you have turned on the power switch, do not touch the potential sensor

assembly.

11) Make the following selections in service mode, and check to make sure

that the reading is between 0 and 30 during initial rotation: COPIER>

DISPLAY> DPOT> DPOT-K.

MEMO:

1. If the reading is as indicated in Method 1 but is not in Method 2, suspect

dirt on the sensor or a fault in the potential measurement unit.

2. If the reading is as indicated in both Method 1 and Method 2, assume

that the signal path and the operation from the potential sensor unit to the

microprocessor on the DC controller PCB are normal.

12) Turn off the power switch.

13) Remove the potential sensor checker electrode.

14) Mount the potential sensor support plate.

15) Turn on the power switch.

14.7.9 Checking the Environment Sensor

0010-9333

iR7105 / iR7095 / iR7086

1) Checking the Environment Sensor

Make the following selections in service mode, and check and record the

temperature/ humidity indicated on the screen in the control panel:

COPIER > DISPLAY > ANALOG.

Data A

'TEMP' deg C ........... data A1

'HUM' % ........... data A2

2) Press the Rest key twice to turn off the power switch.

3) Remove the environment sensor, and fit the environment sensor jig

(FY9-3014) in its place.

4) Turn on the power switch, and leave the machine alone for 5 min.

5) Make the following selections in service mode, and check and record

the temperature/ humidity indicated on the screen in the control panel:

COPIER > DISPLAY > ANALOG:

Data B

'TEMP' deg C ........... data B1

'HUM' % ........... data B2

6) Compare data A and data B.

- difference between data A 1 and data B1 is 0 -/+ 5

- difference between data A2 and data B2 is 0 -/+ 20

If the difference between data A and data B is outside the range, replace the

environment sensor.

7) Press the Reset key twice, and turn off the power switch.

8) Detach the environment sensor jig, and fit the environment sensor.

9) Put back all covers.

The environment sensor jig (FY9-3014) is precisely adjusted at the factory.

Be sure to keep it in an air-tight case with a drying agent.

14.8 Pickup/Feeding System

14.8.1 Orientation of the Deck/Cassette Pickup Roller

0010-9337

iR7105 / iR7095 / iR7086

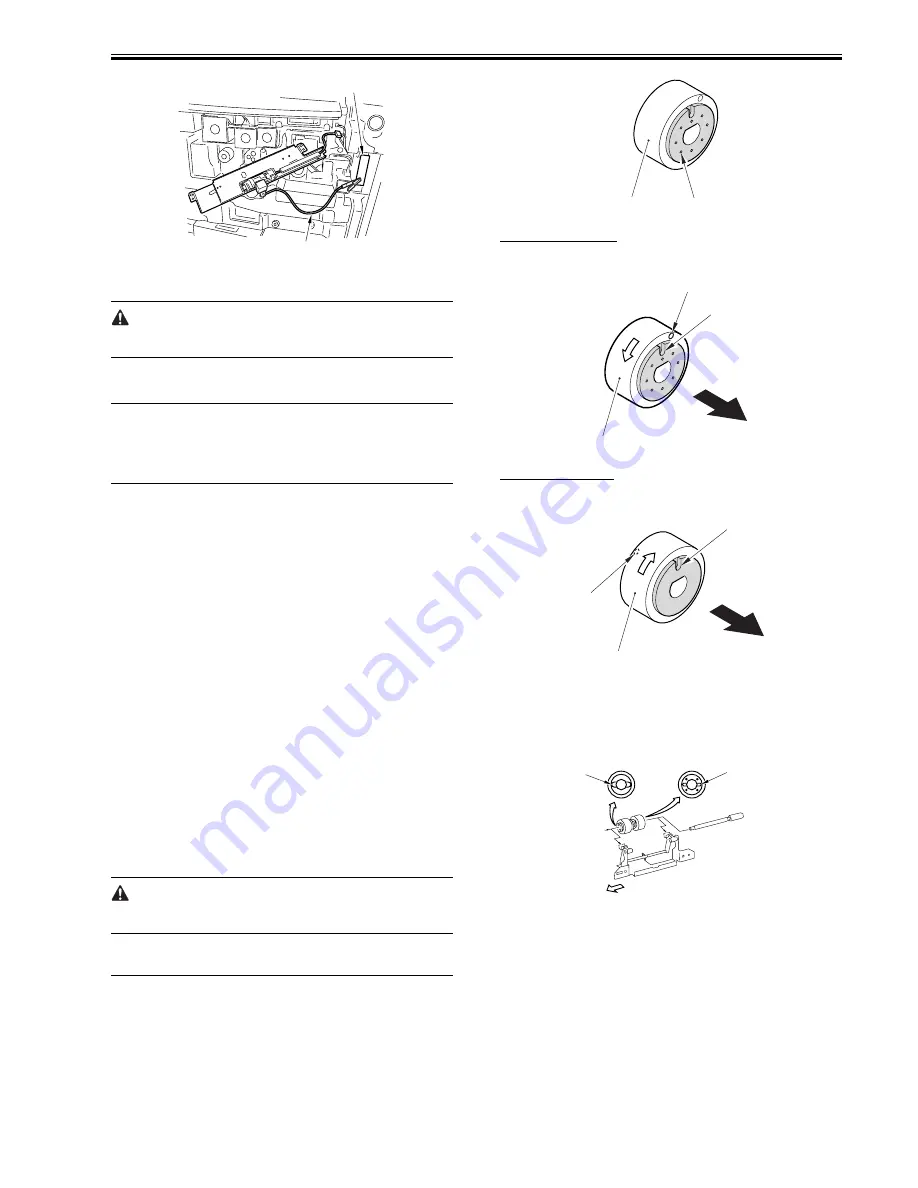

Mount the pickup roller using the steps used to remove it but in reverse while

keeping the following in mind:

- The pickup roller used in the front of the machine and the one used in the

rear are not compatible with each other.

- The pickup roller [1] used at the front of the machine is identified by 8

markings [2] on its collar.

F-14-47

Pickup Roller at the Front

Mount the pickup roller [1] so that the marking [2] on the side and the cut-

off [3] in the collar are toward the front of the machine.

F-14-48

Pickup Roller at the Rear

Mount the pickup roller [1] so that the round marking [2] on its side is toward

the front of the machine while the cut-off [2] in the collar is toward the rear.

F-14-49

14.8.2 Orientation of the Deck/Cassette Separation Roller

0010-9338

iR7105 / iR7095 / iR7086

When replacing the separation roller, be sure that it is oriented as shown

F-14-50

14.8.3 Orientation of the Feeding Roller of the Deck/

Cassette Pickup Assembly

0010-9339

iR7105 / iR7095 / iR7086

When mounting the feeding roller assembly to the deck/cassette pickup as-

sembly, be sure that the belt pulley [2] is to the front of the machine. When

mounting the feeding roller [3] to the feeding roller shaft [4], be sure that the

round marking [5] is toward the front of the machine.

[1]

[2]

[1]

[2]

[1]

[2]

[3]

Front

[1]

[2]

[3]

Rear

Wider notch

Narrower notch

(front of machine)

Summary of Contents for iR7086

Page 1: ...Sep 7 2007 Service Manual iR7105 7095 7086 Series...

Page 2: ......

Page 6: ......

Page 26: ...Contents...

Page 27: ...Chapter 1 Introduction...

Page 28: ......

Page 30: ......

Page 32: ...Chapter 1 1 2 Not all products are necessarily available in all sales areas...

Page 55: ...Chapter 2 Installation...

Page 56: ......

Page 150: ......

Page 151: ...Chapter 3 Basic Operation...

Page 152: ......

Page 154: ......

Page 159: ...Chapter 4 Main Controller...

Page 160: ......

Page 162: ......

Page 183: ...Chapter 5 Original Exposure System...

Page 184: ......

Page 228: ......

Page 229: ...Chapter 6 Laser Exposure...

Page 230: ......

Page 232: ......

Page 238: ...Chapter 6 6 6 F 6 7 1 Laser light 2 Laser shutter 1 2 1 2 2 1...

Page 240: ......

Page 241: ...Chapter 7 Image Formation...

Page 242: ......

Page 246: ......

Page 294: ......

Page 295: ...Chapter 8 Pickup Feeding System...

Page 296: ......

Page 300: ......

Page 353: ...Chapter 9 Fixing System...

Page 354: ......

Page 378: ......

Page 379: ...Chapter 10 External and Controls...

Page 380: ......

Page 384: ......

Page 394: ...Chapter 10 10 10 F 10 7...

Page 417: ...Chapter 11 MEAP...

Page 418: ......

Page 420: ......

Page 466: ......

Page 467: ...Chapter 12 RDS...

Page 468: ......

Page 470: ......

Page 479: ...Chapter 13 Maintenance and Inspection...

Page 480: ......

Page 482: ......

Page 496: ......

Page 497: ...Chapter 14 Standards and Adjustments...

Page 498: ......

Page 526: ......

Page 527: ...Chapter 15 Correcting Faulty Images...

Page 528: ......

Page 530: ......

Page 560: ......

Page 561: ...Chapter 16 Self Diagnosis...

Page 562: ......

Page 564: ......

Page 584: ......

Page 585: ...Chapter 17 Service Mode...

Page 586: ......

Page 588: ...Contents 17 8 1 1 COPIER Items 17 94...

Page 688: ......

Page 689: ...Chapter 18 Upgrading...

Page 690: ......

Page 692: ......

Page 696: ...Chapter 18 18 4...

Page 713: ...Chapter 18 18 22 formatting and download the system software once again...

Page 726: ...Chapter 19 Service Tools...

Page 727: ......

Page 729: ......

Page 733: ......

Page 734: ...Sep 7 2007...

Page 735: ......