Chapter 14

14-20

a. Outline

If image faults occur, it is important to find out whether the cause is in the

latent static image formation block (including the photosensitive drum and

the potential control system) or it is in the developing/transfer system, requir-

ing a check on the surface potential. (You can check the surface potential in

service mode.)

b. Disabling the Auto Control Mechanisms

As a way of checking the mechanisms used for corona current control, lamp

intensity control, or developing bias control, you may disable the auto con-

trol mechanisms (hereafter, non-auto control mode).

As a first-aid measure when a fault exists in the auto control mechanism, you

may use non-auto control mode; keep in mind that all outputs in non-auto

control mode are fixed to standard values.

1. Procedure

1) Make the following selections in service mode, and enter '0':

COPIER > OPTION > BODY > PO-CNT.

2) Press the Reset key twice.

In non-auto control mode, all settings used for coronal current control, inten-

sity control, developing bias control will be set to standard settings stored in

ROM.

2. Making Use of Non-Auto Control Mode

If a fault occurs in images, use the mode to find out if the cause is on the input

side or output side of the microprocessor on the DC controller PCB.

In non-auto control mode, if the fault is corrected somewhat, you may sus-

pect the potential measurement unit or the DC controller PCB.

c. Zero-Level Check

One way of finding out if the surface potential control circuit is good or not

is to use a zero-level check.

MEMO:

A zero-level check is made to see if the microprocessor registers 0 V when

the surface potential of the drum is 0 V.

Using the result of the check, you can find out if the microprocessor on the

DC controller PCB or the measurement unit is good or not; a zero-level

check may take either of the following two methods:

1. Method 1

1) Turn off the power switch.

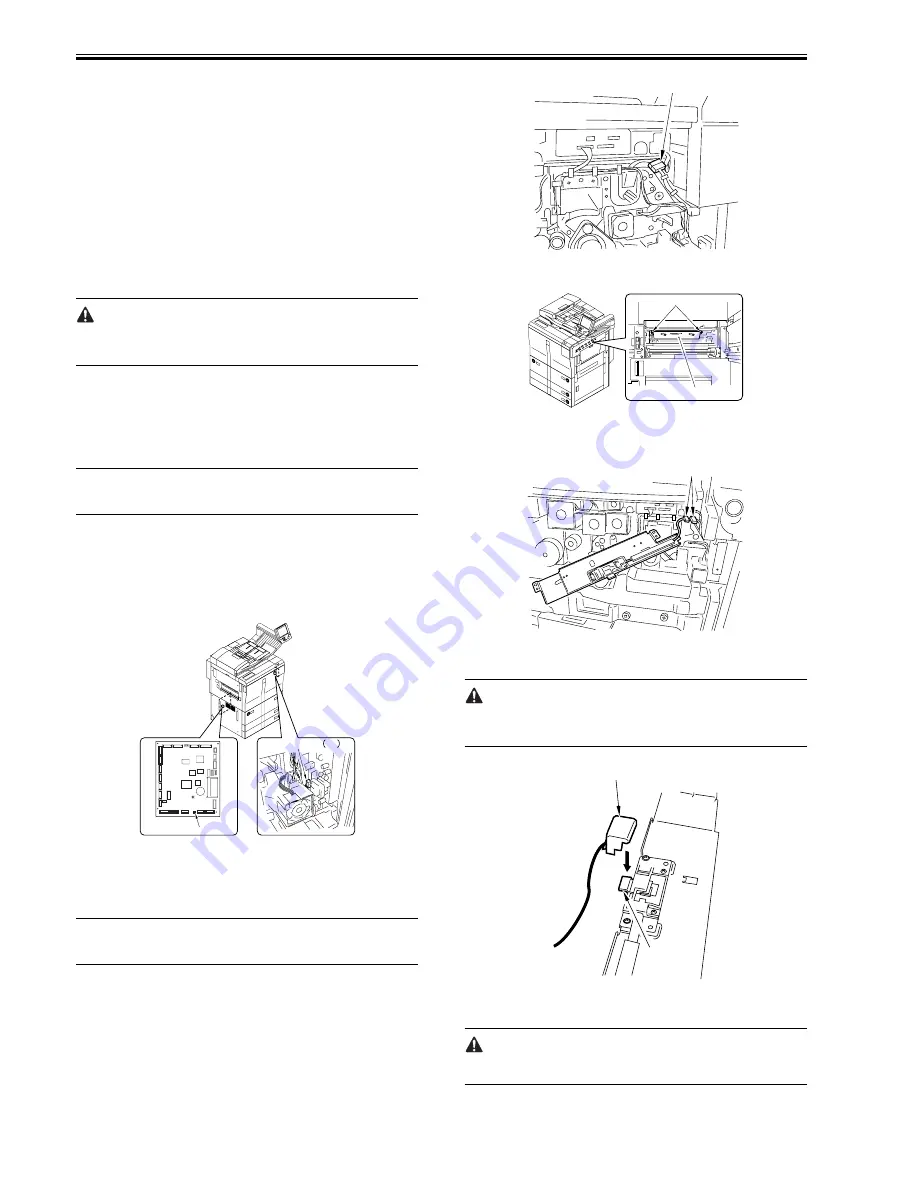

2) Short the connectors J522-1 and -2 on the DC controller PCB with a

jumper wire, and disconnect the connector J3 of the potential control

PCB.

F-14-41

3) Fit the door switch actuator into the door switch assembly, and turn on the

power switch.

4) Make the following selections in service mode, and check to see if the

reading is between 0 and 30 during initial rotation: COPIER> DISPLAY>

DPOT> DPOT-K.

MEMO:

If the reading is not as indicated, you may suspect a fault in the DC controller

PCB.

5) Turn off the power switch, and detach the door switch actuator.

6) Detach the jumper wire from the DC controller PCB.

7) Connect the connector to J3 of the potential control PCB.

8) Turn on the power switch.

2. Method 2

1) Turn off the power switch.

2) Remove the developing assembly, and slide out the process unit.

3) Disconnect the connector [1] of the potential sensor.

F-14-42

4) Remove the 2 screws [1], and detach the potential sensor support plate [2].

F-14-43

5) Put back the developing assembly and the process unit.

6) Connect the connector [1] of the potential sensor.

F-14-44

7) Fit the potential sensor checker electrode (FY9-3041) [2] to the potential

sensor [1].

When fitting the checker electrode to the potential sensor, be sure that the

magnet of the checker electrode will not come into contact with the potential

sensor cover.

F-14-45

8) Connect the cable [1] of the potential sensor checker electrode to the

frame (GND) [2] of the machine.

Never bring the clip into contact with the sensor cover. Be sure to keep it ful-

ly away from the sensor window.

Connector

J3

J522

[1]

[2]

[1]

[1]

[1]

[2]

Summary of Contents for iR7086

Page 1: ...Sep 7 2007 Service Manual iR7105 7095 7086 Series...

Page 2: ......

Page 6: ......

Page 26: ...Contents...

Page 27: ...Chapter 1 Introduction...

Page 28: ......

Page 30: ......

Page 32: ...Chapter 1 1 2 Not all products are necessarily available in all sales areas...

Page 55: ...Chapter 2 Installation...

Page 56: ......

Page 150: ......

Page 151: ...Chapter 3 Basic Operation...

Page 152: ......

Page 154: ......

Page 159: ...Chapter 4 Main Controller...

Page 160: ......

Page 162: ......

Page 183: ...Chapter 5 Original Exposure System...

Page 184: ......

Page 228: ......

Page 229: ...Chapter 6 Laser Exposure...

Page 230: ......

Page 232: ......

Page 238: ...Chapter 6 6 6 F 6 7 1 Laser light 2 Laser shutter 1 2 1 2 2 1...

Page 240: ......

Page 241: ...Chapter 7 Image Formation...

Page 242: ......

Page 246: ......

Page 294: ......

Page 295: ...Chapter 8 Pickup Feeding System...

Page 296: ......

Page 300: ......

Page 353: ...Chapter 9 Fixing System...

Page 354: ......

Page 378: ......

Page 379: ...Chapter 10 External and Controls...

Page 380: ......

Page 384: ......

Page 394: ...Chapter 10 10 10 F 10 7...

Page 417: ...Chapter 11 MEAP...

Page 418: ......

Page 420: ......

Page 466: ......

Page 467: ...Chapter 12 RDS...

Page 468: ......

Page 470: ......

Page 479: ...Chapter 13 Maintenance and Inspection...

Page 480: ......

Page 482: ......

Page 496: ......

Page 497: ...Chapter 14 Standards and Adjustments...

Page 498: ......

Page 526: ......

Page 527: ...Chapter 15 Correcting Faulty Images...

Page 528: ......

Page 530: ......

Page 560: ......

Page 561: ...Chapter 16 Self Diagnosis...

Page 562: ......

Page 564: ......

Page 584: ......

Page 585: ...Chapter 17 Service Mode...

Page 586: ......

Page 588: ...Contents 17 8 1 1 COPIER Items 17 94...

Page 688: ......

Page 689: ...Chapter 18 Upgrading...

Page 690: ......

Page 692: ......

Page 696: ...Chapter 18 18 4...

Page 713: ...Chapter 18 18 22 formatting and download the system software once again...

Page 726: ...Chapter 19 Service Tools...

Page 727: ......

Page 729: ......

Page 733: ......

Page 734: ...Sep 7 2007...

Page 735: ......