5

5

5-114

5-114

Adjustment > Auxiliary Adjustment > Adjusting Engagement/Disengagement Position of Saddle Disengagement Roller > Procedure

Adjustment > Auxiliary Adjustment > Adjusting Engagement/Disengagement Position of Saddle Disengagement Roller > Procedure

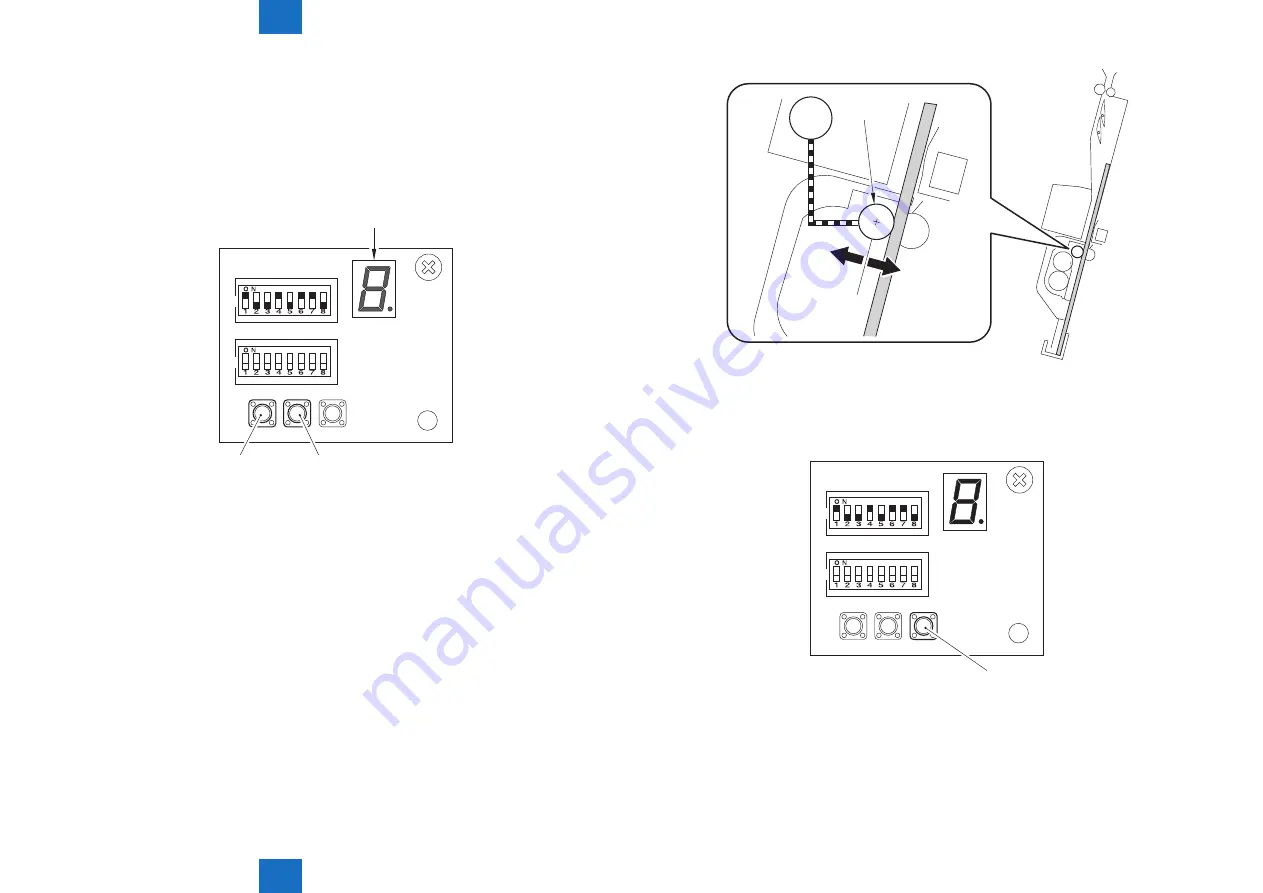

3) Pressing switch SW383 [1] or SW384 [2] determines adjustment level.

By pressing SW383 once, the LED [3] indicates "-1" and the pressure applied to the

disengagement roller [1] is reduced (the disengagement roller is moved in A direction).

In the same way, by pressing SW384 once, the LED [3] indicates "+1" and the pressure

applied to the disengagement roller [1] is increased (the disengagement roller is moved in

B direction).

• Adjustment range: -8 to +8 (0.3mm-change per unit)

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[1]

[2]

[3]

F-5-274

M102

[1]

A B

<Reference>

As the plus adjustment value is specified, the feed performance improves.

4) Press switch SW385 [1] again to complete this adjustment.

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[1]

5) Execute booklet print from the saddle and check that there is no displacement in staple

position.

F-5-275

F-5-276

Summary of Contents for Finisher-AK1

Page 8: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Page 10: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Page 55: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Page 309: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Page 361: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...