October 2012

8-29

ColorQube 8570/8870 Service Manual

Print Process

Theory of Operation

Xerox Internal Use Only - Revised, 3rd Revision

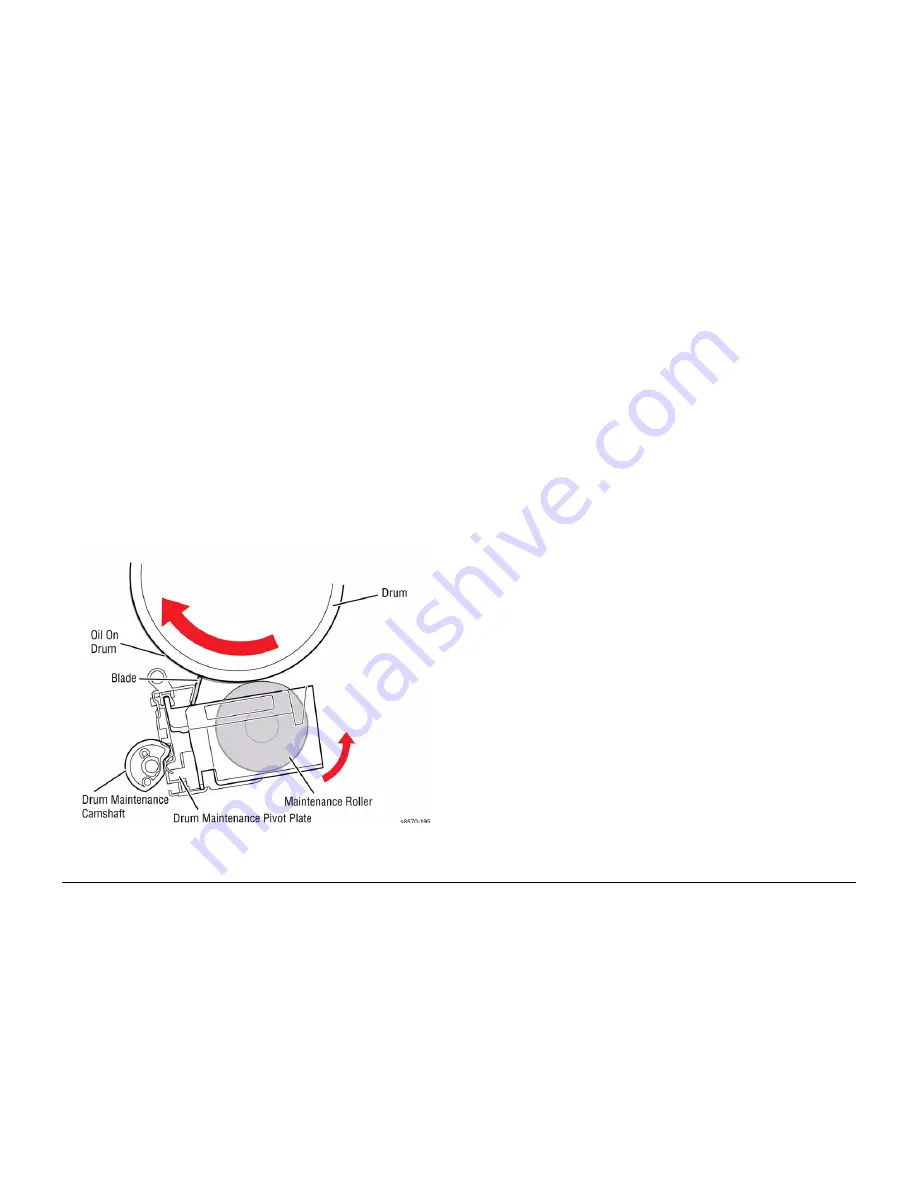

Drum Maintenance System

The Drum Maintenance System creates a thin layer of silicone oil on the surface of the Drum

prior to printing. The oil keeps the ink from sticking to the Drum’s surface and facilitates image

transfer to the media. The oil is contained in a porous foam Roller in the Drum Maintenance

Unit.

Prior to each print, the Process Drive rotates the Drum Maintenance Camshaft to move the

Drum Maintenance Pivot Plate, forcing the oil Roller and Wiper Blade against the Drum. The

Wiper Blade produces a smooth and even oil film across the Drum’s surface. The excess oil

drains back into the Drum Maintenance Unit through a felt filter for reuse. As the Drum com-

pletes one rotation, the Process Drive rotates the Cam lowering the oil Roller and Wiper Blade

away from the Drum.

The Drum has a floating deadband area. The deadband is a narrow section of the Drum’s sur-

face containing excess oil and other debris cleared by the Drum Maintenance Wiper Blade. An

oil bar is left on the Drum surface in this deadband area as the Blade is lowered from the Drum.

The deadband area’s location is controlled to keep it outside of the Drum’s image area.

An EEPROM, built-in to the Drum Maintenance Unit, stores the number of oiling cycles per-

formed by the Drum Maintenance System to track consumable life. At startup, four oiling cycles

are performed to condition the Drum.

Figure 17 Drum Maintenance

Printhead Maintenance

To perform a Printhead maintenance cycle, the Printhead is first tilted away from the Drum to

allow the Wiper Blade to pass by. The Wiper Blade is then raised in front of the Printhead. The

media path drive governs wiper movement when it engages the Head Maintenance Clutch on

the exit shaft of the system. The Purge Pump applies pressure to the ink reservoir for approxi-

mately 2.5 seconds. Valves in the reservoir seal when pressure is applied. The pressurization

ejects a small amount of ink from the jets. Following the pressure purge, the Printhead tilts into

the Wiper Blade and the wipe cycle begins. The pump runs again with the Solenoid for approx-

imately 30 seconds, creating a neutral balance between pressure and ink. The Wiper Blade

lowers and wipes excess ink from the jets into the Waste Tray. A proper purge covers the

length of the Waste Tray with a single layer of ink about 20 mm wide.

The level of the ink in the reservoir is kept constant. If the purge tubing is pinched, the Print-

head may not purge properly. In addition, because the purge tubing also acts as a vent to

atmosphere when not purging, a more serious failure can occur if the ink overfills and the res-

ervoir cannot vent properly.

Содержание COLORQUBE 8570

Страница 1: ...ColorQube 8570 8870 Printer ColorQube 8570 8870 Service Manual Xerox Internal Use Only...

Страница 2: ......

Страница 152: ...October 2012 3 2 ColorQube 8570 8870 Service Manual Revised 3rd Revision Xerox Internal Use Only Image Quality...

Страница 196: ...October 2012 4 2 ColorQube 8570 8870 Service Manual Revised 3rd Revision Xerox Internal Use Only Repairs and Adjustments...

Страница 304: ...October 2012 5 2 ColorQube 8570 8870 Service Manual Revised 3rd Revision Xerox Internal Use Only Parts List...

Страница 316: ...October 2012 6 2 ColorQube 8570 8870 Service Manual Revised 3rd Revision Xerox Internal Use Only General Troubleshooting...

Страница 372: ...October 2012 7 2 ColorQube 8570 8870 Service Manual Revised 3rd Revision Xerox Internal Use Only Wiring Data...

Страница 392: ...October 2012 8 2 ColorQube 8570 8870 Service Manual Revised 3rd Revision Xerox Internal Use Only Theory of Operation...

Страница 423: ......