Manual 26247

2301D/2301D-EC Digital Control

Woodward

49

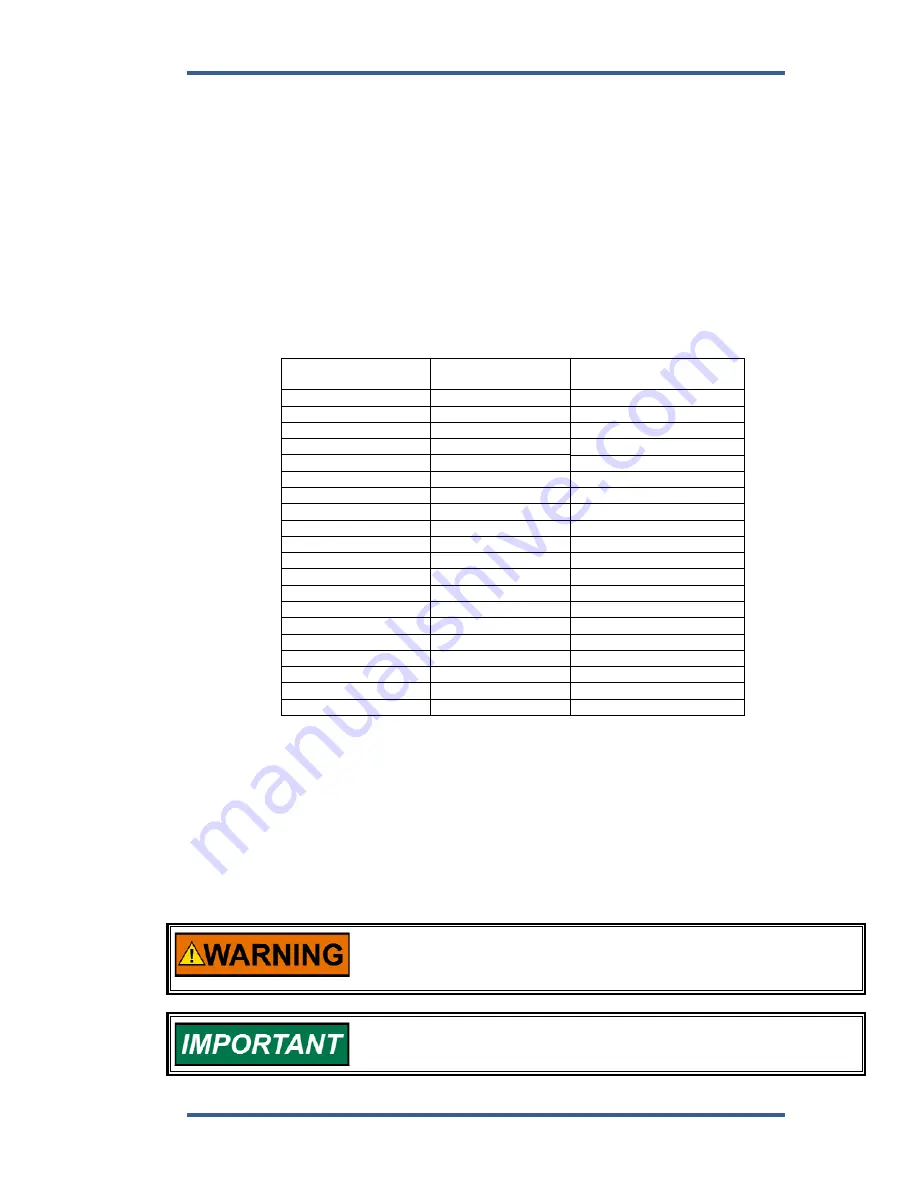

The table below aids in collecting the data for the Gain Plot. When entering

the values into the control, the software will not allow overlapping the

breakpoint values (that is, Breakpoint A must be less than breakpoint B,

which must be less than breakpoint C, etc).

Gain settings reflect the sensitivity of the engine load to fuel demand as

shown in Figure 3-7. Flat portions of the engine plot will require relatively

small values of gain, steep portions of the plot will require larger gain

numbers (actuator has to move a lot to pickup small amount of load).

d.

Create a plot of the system by plotting PID GAIN as a function of load. A

typical result is shown in Figure 3-7.

The following table may help in the construction of the plot. Use as many

load steps as possible, it is not necessary to use all 20 points given below.

Load/RPM Point

Gain (for good

control)

Actuator or kW Output or

Speed

Load/RPM Point 1

Load/RPM Point 2

Load/RPM Point 3

Load/RPM Point 4

Load/RPM Point 5

Load/RPM Point 6

Load/RPM Point 7

Load/RPM Point 8

Load/RPM Point 9

Load/RPM Point 10

Load/RPM Point 11

Load/RPM Point 12

Load/RPM Point 13

Load/RPM Point 14

Load/RPM Point 15

Load/RPM Point 16

Load/RPM Point 17

Load/RPM Point 18

Load/RPM Point 19

Load/RPM Point 20

2. Set Gain A to the value recorded at point 1b. This should give good control at

no load.

3. Use the plot of the engine to determine the linearity of the fuel system. This

curve should be linearized between inflection points as shown in Figure 3-7.

4. Set the Gain A Breakpoint for the actuator output at or slightly below the load

value at the min load point. Set the GAIN value at breakpoint A.

5. Set the Gain B Breakpoint at the point slightly above the first inflection point

in the load plot. Gain B should now be adjusted to obtain good control at the

inflection point B. Note: you may already have obtained the correct value in

Step 1c.

Be prepared to change the dynamics settings since the actuator

bump transient may stimulate instability, which could result in an

overspeed condition.

BUMP ENABLE must be set to TRUE to enable the BUMP ACT

function. See the ACTUATOR BUMP menu.

Содержание 2301D

Страница 12: ...2301D 2301D EC Digital Control Manual 26247 4 Woodward Figure 1 1a 2301D Outline Drawing Ordinary Locations ...

Страница 13: ...Manual 26247 2301D 2301D EC Digital Control Woodward 5 Figure 1 1b 2301D Outline Drawing Hazardous Locations ...

Страница 14: ...2301D 2301D EC Digital Control Manual 26247 6 Woodward Figure 1 2a 2301D Plant Wiring Diagram sheet 1 ...

Страница 16: ...2301D 2301D EC Digital Control Manual 26247 8 Woodward Figure 1 2c 2301D Plant Wiring Diagram notes ...

Страница 51: ...Manual 26247 2301D 2301D EC Digital Control Woodward 43 Figure 3 4 Typical Transient Response Curves ...

Страница 127: ...Manual 26247 2301D 2301D EC Digital Control Woodward 119 ...

Страница 129: ...Declarations ...