2301D/2301D-EC Digital Control

Manual 26247

28

Woodward

If an application configuration has been previously saved to a *.CFG file,

the saved set of parameters can be loaded into the 2301D as a group by

selecting the

Load Application Settings

icon.

To save the configuration to a file in the external computer for backup or

download later into another 2301D when a similar system is being set up, select

the

Save Application Settings

icon. All the tunable values presently set in the

control will be saved to a file and can be loaded into this 2301D control to

reprogram it to the saved values or into another 2301D at a later time.

Configure Menu Descriptions

A**ENGINE & SPEED CONTROL**

01 ENTER RATED SPEED (RPM)

dflt = 900 (0, 4000)

Set to the rated synchronous rpm of the engine/generator. This will typically be a

value from the following table:

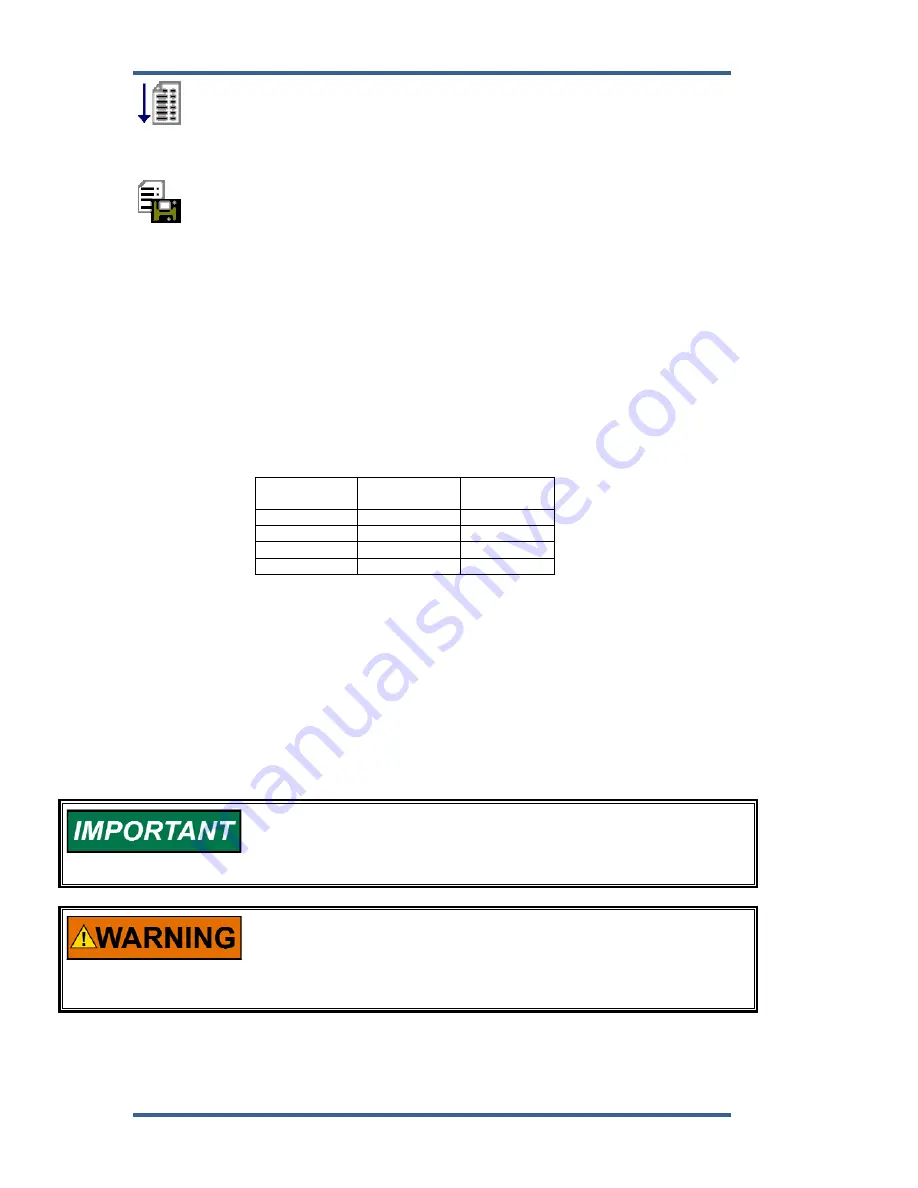

Generator

Poles

60 Hz

Generator

50 Hz

Generator

2

3600 rpm

3000 rpm

4

1800 rpm

1500 rpm

6

1200 rpm

1000 rpm

8

900 rpm

750 rpm

This value is used to set the 2301D speed sensor hardware to software

conversion. The rated speed can be varied in Service for testing. If a rated speed

other than values listed here is entered, the calculated generator frequency

shown in **DISPLAY MENU** may not be correct.

02 ENTER NUM OF GEAR TEETH

dflt = 60 (8, 500)

This is the number of teeth or holes of the gear or flywheel that the speed sensor

is on. If the gear is on the cam shaft or other drive not turning at the prime mover

speed, the number of teeth needs to be adjusted to compensate. EXAMPLE: If

the gear is rotating at one-half the engine speed enter one-half the number of

actual teeth.

The maximum input frequency that can be measured by the speed

sensing circuit is 25 000 Hz. Therefore to allow for transient

conditions, the (Number of Teeth x Rated rpm) / 60 should be less

than 19 000.

The number of gear teeth is used by the control to convert pulses

from the speed-sensing device to engine rpm. To prevent possible

serious injury from an overspeeding engine, make sure the control is

properly programmed to convert the gear-tooth count into engine

rpm. Improper conversion could cause engine overspeed.

Содержание 2301D

Страница 12: ...2301D 2301D EC Digital Control Manual 26247 4 Woodward Figure 1 1a 2301D Outline Drawing Ordinary Locations ...

Страница 13: ...Manual 26247 2301D 2301D EC Digital Control Woodward 5 Figure 1 1b 2301D Outline Drawing Hazardous Locations ...

Страница 14: ...2301D 2301D EC Digital Control Manual 26247 6 Woodward Figure 1 2a 2301D Plant Wiring Diagram sheet 1 ...

Страница 16: ...2301D 2301D EC Digital Control Manual 26247 8 Woodward Figure 1 2c 2301D Plant Wiring Diagram notes ...

Страница 51: ...Manual 26247 2301D 2301D EC Digital Control Woodward 43 Figure 3 4 Typical Transient Response Curves ...

Страница 127: ...Manual 26247 2301D 2301D EC Digital Control Woodward 119 ...

Страница 129: ...Declarations ...