149

Troubles

Causes

Measures

Serial communication

control fails

The RS-232C cable is connected to the

wrong connector (RETURN OUT).

Connect the RS-232C cable to “RS-232C”

connector on the rear of the controller.

Communication parameter settings

are changed when the backup data is

restored to the laser marker.

Check the communication parameter settings.

If Ethernet is used, confirm the IP address and

other parameters.

When the backup data is restored to the laser

marker, communication parameter settings are

overwritten with the backup data.

Command data is not received from

external equipment.

Using commercially available line monitor or

protocol analyzer, check if external equipment

transmits data.

Communication data format is

incorrect.

Check if format of communication data command

transmitted from external equipment is correct.

•

Check if start code STX (02: HEX) is placed at

beginning of transmitted data.

•

Check if the delimiter is added to the end of the

transmission data. ([CR] (0D: HEX) or [CR+LF]

(0D: HEX 0A: HEX) for RS-232C, [CR] (0D:

HEX) for Ethernet)

READY signal is not

turned to ON.

Alarm or error occurs.

Release the alarm or warning referring to the

measures for the corresponding error code.

Laser has not been pumped.

Refer to “The laser is not pumped”.

Internal shutter is closed.

Open the internal shutter.

•

When controlling the shutter by I/O signal,

turn off DIP switch No. 2 and turn on terminal

SHUTTER in terminal block.

•

When controlling the shutter by serial

communication, turn on DIP switch No. 2 and

send shutter command (SHT).

* To change the DIP setting, the switch of the

laser marker should be set at power OFF state.

The changing operation of the file data

is unfinished.

It takes from tens of msec. to several seconds to

complete the changing file data.

During that time, READY output is in OFF status.

Enter marking trigger signal after making sure that

[READY] output is on if you want to change file to

another one.

Marking data is not sent to the laser

marker from the external devices, in

case of using Rank Function, External

Offset Function, or Serial Data Input

Function.

If rank, external offset and serial data functions

are enabled while marking conditions are not

yet specified, enter respective data per marking

cycle.

Enter marking trigger signal after making sure

that [READY] output is on or checking status of

READY using status request command.

Under serial communication control:

Mark trigger signal is ON while the

command reception permission (MKM

command) is set to “Reception mode

ON”.

Set “reception mode OFF” for command reception

permission (MKM command). Before entering

marking trigger signal, use status request

command [STS] to make sure that READY is on.

ME-LP400V-EX-6

Содержание LP-400 Series

Страница 12: ...1 Before External Control ME LP400V EX 6...

Страница 24: ...2 Control by I O ME LP400V EX 6...

Страница 56: ...3 Control by Serial Communication RS 232 Ethernet ME LP400V EX 6...

Страница 141: ...Troubleshooting ME LP400V EX 6...

Страница 158: ...Character Code Table ME LP400V EX 6...

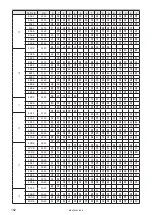

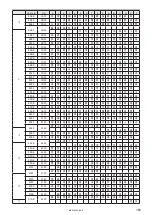

Страница 166: ...166 Shift JIS JIS 0 1 2 3 4 5 6 7 8 9 A B C D E F 983F 4F20 984F 4F30 985F 4F40 986F 4F50 ME LP400V EX 6...

Страница 176: ...Index ME LP400V EX 6...

Страница 179: ...No 9000 0062 17V...

Страница 180: ...Panasonic Industrial Devices SUNX Co Ltd 2003 2018 July 2018 9000 0062 17V...