147

Moving objects

Troubles

Causes

Measures

Marking cannot be done.

Encoder signal is off.

Check for proper connection to encoder.

Marking is sometimes

skipped.

(E800 occurs.)

Marking trigger signal is entered before

current marking is finished.

•

Increase scan speed setting of laser marker.

•

Decrease delay distance setting of laser

marker.

•

Reduce feeder speed.

•

Increase marking interval (interval between

objects on feeder).

Characters unreadable

Feed direction is not correct.

Match feed direction with laser marker operation.

Speed changes at conveyor junction.

If conveyors are coupled, avoid marking near

conveyor junction.

Actual speed and preset speed for

feeding objects are different due to

slippage of objects.

Remove cause of object slippage.

Pulse setting of encoder is not correct.

Measure the number of encoder pulses and

adjust “Number of encoder pulses”.

Encoder is out of order.

Check encoder for proper function.

Marking position is

unstable.

Positional misalignment is likely to

occur due to meandering motion of

conveyor.

Secure objects to prevent misalignment.

Marking character pitch

is unstable.

The line speed at the marking position

is different from the speed at the

installation site of the encoder.

Place the encoder as close as possible to the

marking position.

Decrease the encoder resolution to block the

effect of the line speed fluctuation.

Note that the minimum value of the encoder pulse

should be 10 P/mm.

Character is partially

chipped.

Obstacle hinders laser beam.

Remove obstacle between head of laser marker

and object.

Actual spacing between

characters is larger or

small than setting.

Pulse setting of encoder is not correct.

Check setting to be sure that:

•

When using A phase only:

Number encoder pulses = Number of pulses/

mm x 2

•

When using A and B phases:

Number encoder pulses = Number of pulses/

mm x 4

Either A or B phase signal is refused. (A

and B phase used)

Check that signal is applied to A and B phase

terminals of encoder.

Measured number of encoder pulses

differs from calculated one.

Increase or decrease values in “Encoder fine

adjustment” field as appropriate.

•

When the character interval is wide:

Increase the setting.

•

When the character interval is narrow:

Decrease the setting.

ME-LP400V-EX-6

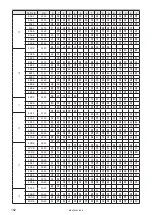

Содержание LP-400 Series

Страница 12: ...1 Before External Control ME LP400V EX 6...

Страница 24: ...2 Control by I O ME LP400V EX 6...

Страница 56: ...3 Control by Serial Communication RS 232 Ethernet ME LP400V EX 6...

Страница 141: ...Troubleshooting ME LP400V EX 6...

Страница 158: ...Character Code Table ME LP400V EX 6...

Страница 166: ...166 Shift JIS JIS 0 1 2 3 4 5 6 7 8 9 A B C D E F 983F 4F20 984F 4F30 985F 4F40 986F 4F50 ME LP400V EX 6...

Страница 176: ...Index ME LP400V EX 6...

Страница 179: ...No 9000 0062 17V...

Страница 180: ...Panasonic Industrial Devices SUNX Co Ltd 2003 2018 July 2018 9000 0062 17V...