2NL/2P8

1-4-8

5011

Bridge conveying sensor 2

stay jam

The bridge conveying sensor 2(BRCS2) does not

turn off during paper feed from cassette 1.

I

5012

The bridge conveying sensor 2(BRCS2) does not

turn off during paper feed from cassette 2.

I

5013

The bridge conveying sensor 2(BRCS2) does not

turn off during paper feed from cassette 3.

I

5014

The bridge conveying sensor 2(BRCS2) does not

turn off during paper feed from cassette 4.

I

5018

The bridge conveying sensor 2(BRCS2) does not

turn off during paper feed from duplex section.

I

5019

The bridge conveying sensor 2(BRCS2) does not

turn off during paper feed from the MP tray.

I

6000

DF paper entry error

DF paper entry sensor (DFPES) turns on before

the eject signal is output from the machine (3000-

sheet finisher).

-

6001

DF paper entry sensor (DFPES) turns on before

the eject signal is output from the machine (1000-

sheet finisher).

-

6020

DF front cover open

DF front upper cover is opened during operation

(3000-sheet finisher).

-

6021

DF front cover is opened during operation (1000-

sheet finisher).

-

6041

DF top cover open

DF top cover is opened during operation (1000-

sheet finisher).

-

6060

MB cover open

MB cover is opened during operation (3000-sheet

finisher).

-

6100

DF paper entry sensor non

arrival jam

DF paper entry sensor (DFPES) does not turned

on even if a specified time has elapsed after the

machine eject signal was received (3000-sheet fin-

isher).

I

6101

DF paper entry sensor (DFPES) does not turned

on even if a specified time has elapsed after the

machine eject signal was received (1000-sheet fin-

isher).

I

6110

DF paper entry sensor stay

jam

DF paper entry sensor (DFPES) does not turned

off within specified time of its turning on (3000-

sheet finisher).

J

6111

DF paper entry sensor (DFPES) does not turned

off within specified time of its turning on (1000-

sheet finisher).

J

6200

DF sub eject sensor non

arrival jam

DF sub eject sensor (DFSES) does not turn on

within specified time of DF paper entry sensor

(DFPES) turning on.

J

Code

Contents

Conditions

Jam

location*

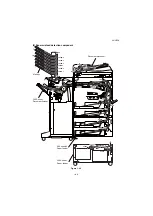

*: Refer to figure 1-4-1 for paper jam location (see page 1-4-1).

Содержание TASKalfa 3010i

Страница 1: ...SERVICE MANUAL Published in September 2016 842NL11B 2NLSM06B Rev B TASKalfa 3010i TASKalfa 3510i ...

Страница 10: ...This page is intentionally left blank ...

Страница 100: ...2NL 2P8 1 2 76 This page is intentionally left blank ...

Страница 286: ...2NL 2P8 1 3 186 This page is intentionally left blank ...

Страница 443: ...2NL 2P8 1 5 59 This page is intentionally left blank ...

Страница 463: ...2NL 2P8 2 1 18 Figure 2 1 23 Duplex conveying section block diagram EPWB DU_SENS DU_CL_REM YC14 5 YC8 1 DUCL DUS ...

Страница 471: ...2NL 2P8 2 2 8 This page is intentionally left blank ...

Страница 532: ...Installation Guide DP 770 B Document processor DP 772 Document processor Installation Guide ...

Страница 568: ...DP 773 Document processor Installation Guide ...

Страница 594: ...PF 791 500 x 2 Paper feeder Installation Guide ...

Страница 602: ...PF 810 3000 sheet deck Installation Guide ...

Страница 615: ...DF 791 3000 sheet finisher Installation Guide ...

Страница 630: ...DF 770 D 1000 sheet finisher Installation Guide ...

Страница 648: ...AK 740 Bridge unit Installation Guide ...

Страница 650: ...MT 730 B Mailbox Installation Guide ...

Страница 665: ...PH 7A C D Punch unit Installation Guide ...

Страница 686: ...DT 730 B Document tray Installation Guide ...

Страница 731: ...5 2013 5 302LC56750 01 H F G D D 6 4 3 7 E C D D M4 8 M4 8 M4 8 M4 8 ...

Страница 732: ...FAX System W B Installation Guide ...