Traverse Installation and Commissioning Guide, Section 2: Network Interface Specifications

DS1 and E1 ECM Placement

Page 2-24

Turin Networks

Release TR3.2.1

DS1 and E1

ECM

Placement

The DS1/E1 and E1 ECMs plug into the main backplane 2 mm connectors of any valid

odd or even slot. The 2-slot DS1/E1 ECM design provides direct cable access to one

(n+1) or two (either n and n+1 or n and n+2) cards (depending on the protection cabling

scheme used) and occupies the width of two slots on the main backplane. The 3-slot E1

ECM design provides direct cable access to two cards (either n and n+1 or n and n+2,

depending on the protection scheme) and occupies the width of three slots (n, n+1, and

n+2) on the main backplane. Plug the ECM into the right-most (n) or center (n+1)

2 mm connectors for 2-slot ECMs, depending on the protection scheme, and the center

(n+1) 2 mm connectors for 3-slot ECMs, as seen from the rear view of the shelf.

For a graphical representation, Section 2—

Network Interface Specifications

Chapter 2—“ECM Interface Specifications,”

ECM Placement at the Traverse Main

DS1 and E1

Card Cabling

Schemes

DS1 and E1 card cabling schemes are as follows:

•

Traverse 2000 DS1 and E1 Card Cabling Schemes

•

Traverse 1600 DS1 and E1 Card Cabling Schemes

•

Traverse 600 DS1 and E1 Card Cabling Schemes

Traverse 2000

DS1 and E1

Card Cabling

Schemes

The Traverse 2000 main backplane design supports 1:1 and 1:2 equipment protection

and unprotected cabling schemes. Both 1:1 and 1:2 equipment protection groups can

start in any odd or even slot.

, Appendix A—“Card Placement Planning and

Guidelines,” page 12-1 for further card placement guidelines and restrictions.

Note:

The Traverse main backplane supports DS1 and E1 protected and unprotected

slots and ports simultaneously.

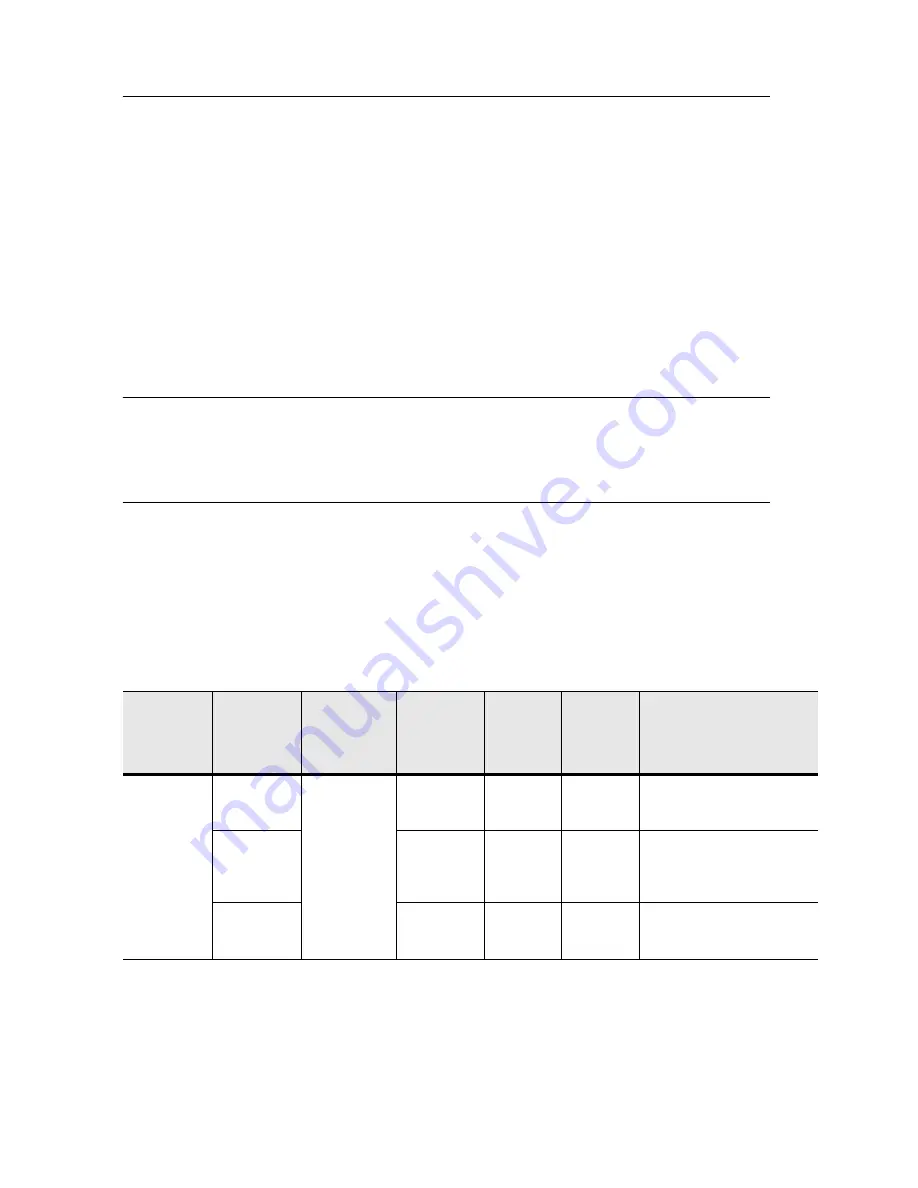

Table 2-10 Traverse 2000 DS1 and E1 Cabling Scheme

Card Type

Cabling

Scheme

ECM Type

(Connector)

Maximum

Protection

Groups

Total # of

Working

Ports

Total # of

ECM

Slots

(In Use)

Comments

(Front Shelf

Perspective)

DS1 (28-port)

1:2 protection

2-slot DS1/E1

(Telco 64)

5

280

15

The center card (n+1) protects

left-adjacent (n) and

right-adjacent (n+2) cards.

1:1 protection

8

224

16

Either the left-adjacent (n) or

right-adjacent (n+2) card from

the protecting card (n+1) is the

working card.

Unprotected

N/A

448

16

The DS1/E1 ECM provides

direct cable access to both cards

(n and n+1).