1-14

Normal setting

For normal setting, you can set five items below:

1

Press the [SETUP] on the operation touch

panel.

2

Press the [SETTINGS].

• If you wish to cancel, press the [<].

Tab Name

Item Name

Outline

HEATER

MAIN HEATER

(default : 40%)

Sets the main heater temperature. This value is displayed in operation

percentage. The main heater dehydrates the surface of the media right

after printing.

Washing Unit

WATER VALVE

(default : 60s)

Sets the timing of the water supply valve. The water supply valve is

opened once in a certain hour (first parameter is “Open Every”) and

remains opened for a certain hour (second parameter is “Remains Open

For”). Both parameters are displayed on the second time scale.

WASHING UNIT

(default : 30s)

Sets the timing of the washing unit. In other word, when a certain hours

have passed after the belt stopped, the washing unit moves down and

stops. This parameter is displayed on the second time scale.

PRESSURE

ROLLER

DETACH AFTER

Set the timing of the pressure roller to move upward. Sets the time of the

pressure roller to move upward after making this DOWN from the

operation touch panel and the belt stops. This parameter is displayed on

the second time scale.

TENSION BAR

MEDIA END

DETECTION

Sets the time for detecting media end after the tension bar moved

downward (TIME FOR DETECTION) on the second time scale.

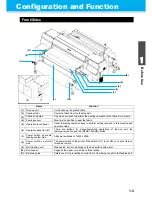

Summary of Contents for TEXTILE JET TX1800B

Page 1: ...MIMAKI ENGINEERING CO LTD URL http www mimaki co jp D202080 14 ...

Page 13: ...xii 1 2 3 4 5 6 How to Read This Operation Manual ...

Page 14: ...xiii ...

Page 40: ...1 26 ...

Page 80: ...2 40 ...

Page 196: ...5 30 ...

Page 205: ...Function Flowchart 6 9 1 2 3 4 Appendix 6 To P 6 10 To P 6 14 To P 6 20 ...

Page 220: ...6 24 ...

Page 221: ...D202080 14 29122011 ...