2-18

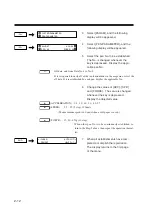

• The autocut is executed when the EOF condition is satisfied and the NR

command is under execution. (Under the EOF command execution and

time out)

In the case where the machine has failed to conduct auto-

cut, it will re-try auto-cut as many as three times while

increasing the cut pressure in increments of 10 g.

If the machine cannot complete auto-cut in the re-tries,

it will enter the online mode after giving an appropriate

error message on the display.

At this time, the pressure setting for the auto-cut and the

pressure established by a cutter parameter will automati-

cally increase by 10 g that will be stored in the plotter.

It should be noted, however, the cutter parameter pres-

sure will be determined by the setting established on the

CAD in the case where the “DOTTED LINE CUT” is

set to the OFF state and the cutting pressure command

will be provided by the CAD.

If the machine finally cannot cut off the paper with a

450-g pressure, it will give a message to prompt for cut-

ter replacement. In this case, be sure to replace the cut-

ter blade with a new one.

When a magazine is loaded on the machine, the machine will

give a message asking whether the cutter blade has been re-

placed. If “YES” meaning that the cutter blade has been re-

placed with a new one is selected, the cutter pressure will be

restored to the default value.

AUTOCUT SETTING

• Do not excessively increase the autocut pressure (press), or it may cause

abnormal damage of the synchroroller, shorter cutter blade service life

and the like.

The autocut means a function to automatically cut off paper at the end of a plot out for one data under roll paper

mode. In this paragraph, the autocut ON/OFF and cutter pressure at the autocut are established.

C o m m a n d

Description

CUT -> WAIT

After autocut execution, the offline is selected.

CUT -> PLOT

After autocut execution, the online is selected wity awaiting

status.

OFF

Autocut will not be executed.

! AUTO CUT

END IN FAILURE

PLEASE CHANGE CUTTER

CHANGE CUTTER BLADE?

YES NO

Summary of Contents for cg-100AP

Page 16: ...xiv ...

Page 70: ...1 54 ...

Page 108: ...2 38 ...

Page 145: ...CHAPTER 4 SELF DIAGNOSIS FUNCTION 4 9 DEMONSTRATION PATTERN 1 2 Demonstration Pattern 1 ...

Page 146: ...4 10 Demonstration Pattern 2 ...

Page 173: ...CHAPTER 6 APPENDIX 6 13 Table of 82 special character codes supported ...

Page 179: ...D200310MAC 2 00 09061999 ...

Page 180: ... MIMAKI ENGINEERING CO LTD 1999 6 Printed in japan ...