1-6

Legal and Safety Information > Notice

SAFETY OF LASER BEAM (USA)

1. Safety of laser beam

This machine has been certified by the manufacturer to Class 1 level under the radiation performance standards

established by the U.S.DHHS (Department of Health and Human Services) in 1968. This indicates that the product is

safe to use during normal operation and maintenance. The laser optical system, enclosed in a protective housing and

sealed within the external covers, never permits the laser beam to escape.

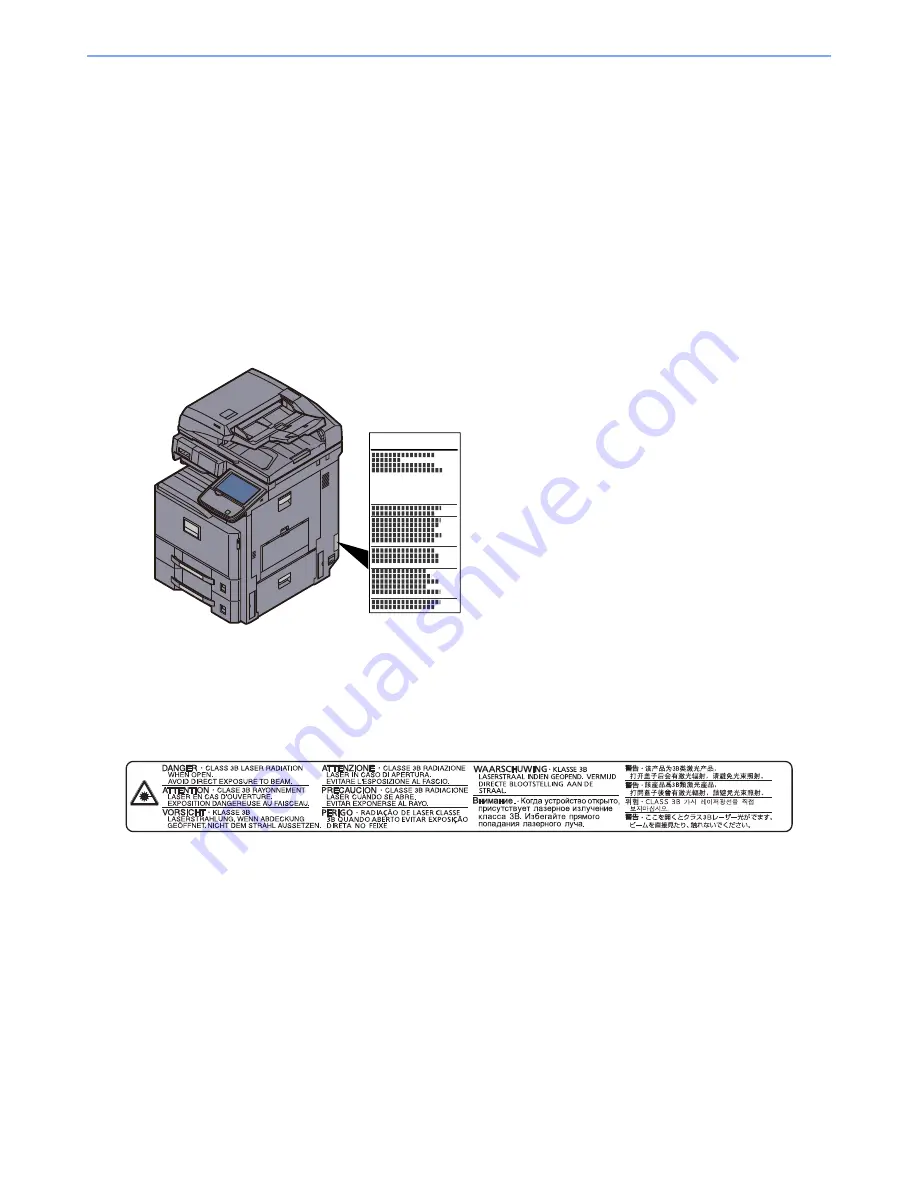

2. The CDRH Act

A laser-product-related act was implemented on Aug. 2, 1976, by the Center for Devices and Radiological Health

(CDRH) of the U.S. Food and Drug Administration (FDA). This act prohibits the sale of laser products in the U.S. without

certification, and applies to laser products manufactured after Aug. 1, 1976. The label shown below indicates

compliance with the CDRH regulations and must be attached to laser products marketed in the United States. On this

machine, the label is on the right.

3. Optical unit

When checking the optical unit, avoid direct exposure to the laser beam, which is invisible. Shown at below is the label

located on the cover of the optical unit.

4. Maintenance

For safety of the service personnel, follow the maintenance instructions in the other section of this manual.

5. Safety switch

The power to the laser unit is cut off when the front cover is opened.

2551ci

Summary of Contents for TASKalfa 2551ci

Page 1: ...OPERATION GUIDE TASKalfa 2551ci ...

Page 17: ...xvi About the Operation Guide this Guide ...

Page 24: ...xxiii Glossary 11 28 Index Index 1 ...

Page 44: ...xliii Menu Map ...

Page 62: ...1 18 Legal and Safety Information Notice ...

Page 116: ...2 54 Installing and Setting up the Machine Transferring data from our other products ...

Page 166: ...3 50 Preparation before Use Registering Destinations in the Address Book ...

Page 178: ...4 12 Printing from PC Printing Data Saved on the Printer ...

Page 322: ...6 72 Using Various Functions Functions ...

Page 444: ...10 4 Troubleshooting Regular Maintenance DP 772 1 2 3 4 ...

Page 445: ...10 5 Troubleshooting Regular Maintenance DP 773 1 2 ...

Page 447: ...10 7 Troubleshooting Regular Maintenance 3 4 5 6 ...

Page 478: ...10 38 Troubleshooting Troubleshooting Cassette 2 1 2 ...

Page 480: ...10 40 Troubleshooting Troubleshooting Large Capacity Feeder 1 500 sheet x 2 1 2 3 B1 B2 ...

Page 481: ...10 41 Troubleshooting Troubleshooting Multi Purpose Tray 1 2 3 4 ...

Page 482: ...10 42 Troubleshooting Troubleshooting Duplex unit 1 2 ...

Page 483: ...10 43 Troubleshooting Troubleshooting Inner Tray Fixing unit 1 2 3 ...

Page 487: ...10 47 Troubleshooting Troubleshooting Job Separator 1 2 3 Bridge Unit Option 1 2 ...

Page 488: ...10 48 Troubleshooting Troubleshooting 1 000 Sheet Finisher Option 1 2 3 D1 D2 2 1 D3 ...

Page 489: ...10 49 Troubleshooting Troubleshooting Clearing a Staple Jam 1 2 3 2 1 CLICK ...

Page 490: ...10 50 Troubleshooting Troubleshooting ...

Page 522: ...11 32 Appendix Glossary ...

Page 531: ...Index 9 ...

Page 532: ...Index 10 ...

Page 533: ......

Page 536: ...First edition 2013 7 2NPKDEN000 ...