—————— Instruction manual ——————

217

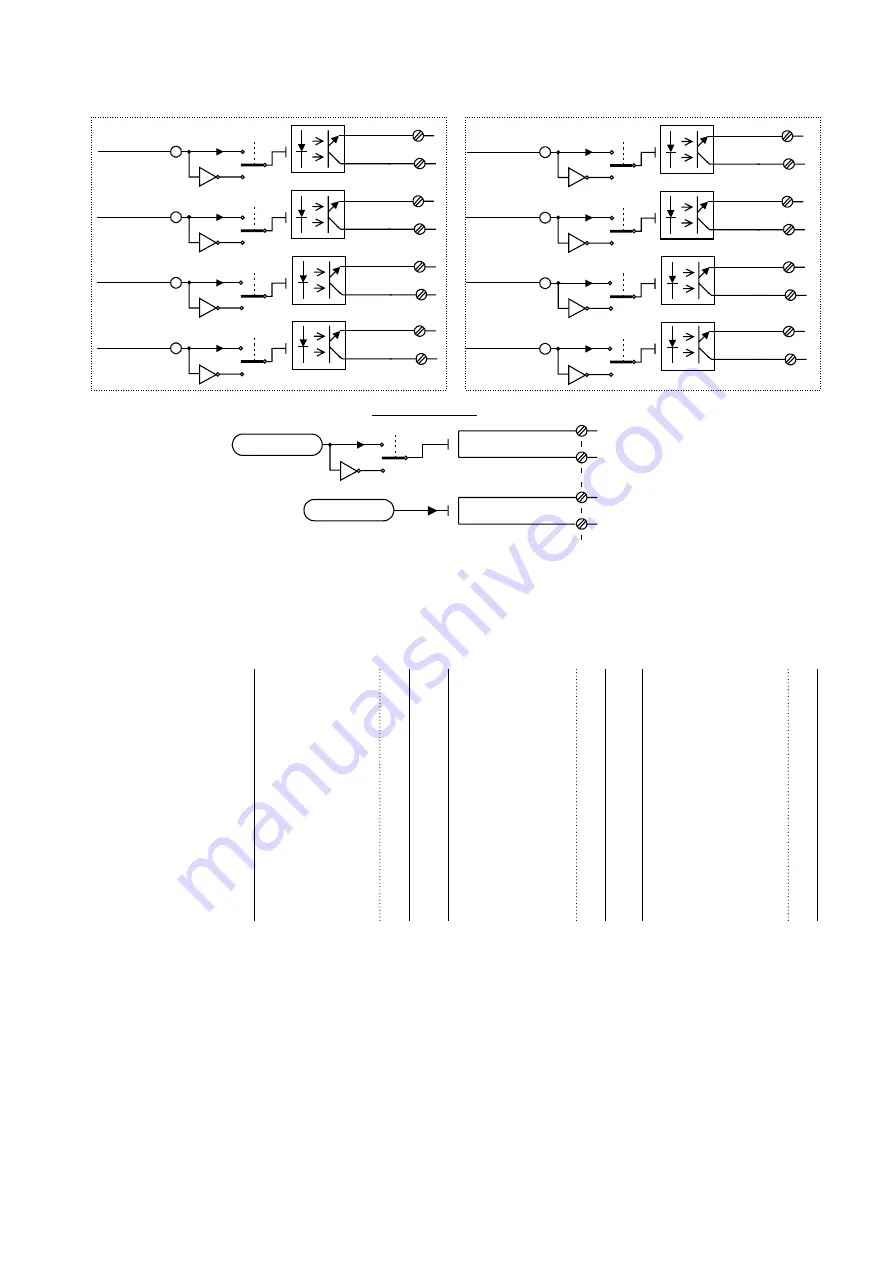

Drive Relay Output

D02

D06

27

7

COM_DO

COM_DO

25

5

D03

D07

28

8

COM_DO

COM_DO

25

5

D04

D08

29

9

COM_DO

COM_DO

25

5

R2NO

75

R2COM

76

D01

D05

26

6

COM_DO

COM_DO

25

5

R1NO

35

R1COM

36

TBO integrated (pos.” A”)

TBO card pos. B (option)

Ok relay func.

Drive healthy

Relay 2

Stop control

Digital output 1

Digital output 5

Ramp +

Curr limit state

Inversion out 2

Inversion out 6

Inversion out 3

Inversion out 7

Inversion out 4

Inversion relay 2

Inversion out 8

Inversion out 1

Inversion out 5

Digital output 2

Digital output 6

Ramp -

Overvoltage

Digital output 3

Digital output 7

Spd threshold

Undervoltage

Digital output 4

Digital output 8

Overld available

Overcurrent

Figure 6.12.3.1: Digital outputs

Digital output XX

Selection of the parameter that is assigned to the digital output concerned. The following

assignments are possible:

OFF

Speed zero thr

Spd threshold

Set speed

Curr limit state

Drive ready

Mot ovrld avail

6)

Overload state

Ramp +

Ramp -

Speed limited

Undervoltage

Overvoltage

Heatsink

Overcurrent

Overtemp motor

External fault

Failure supply

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Pad A bit

Pad B bit

Virt dig input

Torque sign

Stop control

Field loss

Speed fbk loss

Bus loss

Hw opt1 failure

Opt2 failure

Encoder 1 state

Encoder 2 state

Enable seq err

Diameter calc st

1)

Drive healthy

13)

Input 1 cp match

Diam reached

Spd match compl

18

19

20

21

23

24

25

26

28

29

30

31

35

38

42

49

58

59

Acc state

Dec state

Brake comand

2)

Brake failure

3)

Mot ovrld preal

4)

Dvr ovrld preal

5)

Dvr ovrld avail

7)

I2t mot ovrld fail

8)

I2t drv ovrld fail

9)

Mot cur threshld

10)

Overspeed

11)

Delta frequency

12)

Drv rdy to start

14)

BUS control mode

15)

SSC Error

16)

Firing

17)

Cont Current

18)

60

61

62

63

65

66

67

68

69

70

71

72

76

77

79

80

81

1)

Refer to paragraph 6.16.3

PID function

2)

Mechanical brake relay control; indicates the presence of adequate current to sustain

the load (

Torque proving

parameter).

3)

Mechanical brake alarm signal.

4)

this signal is enabled when the thermal image of the motor

Motor I2t accum

=

90 % and returns to 0 when

Motor I2t accum

= 0.

5)

this signal is enabled when the thermal image of the drive

Drive I2t accum

= 90

% and returns to 0 when

Drive I2t accum

= 0.

6)

The default condition of this signal is enabled. It is disabled when

Motor I2t accum

= 100 % and is re-enabled when

Motor I2t accum

= 0.

7)

The default condition of this signal is enabled. It is disabled when

Drive I2t accum

Summary of Contents for TPD32-EV-...-2B

Page 1: ... Instruction manual Industrial Application DC drives TPD32 EV ...

Page 372: ... TPD32 EV 372 9 BLOCK DIAGRAM 9 1 CONTROL BLOCK DIAGRAMS ...

Page 373: ... Instruction manual 373 ...

Page 374: ... TPD32 EV 374 ...

Page 375: ... Instruction manual 375 ...

Page 376: ... TPD32 EV 376 ...

Page 377: ... Instruction manual 377 ...

Page 378: ... TPD32 EV 378 ...

Page 379: ... Instruction manual 379 ...

Page 380: ... TPD32 EV 380 ...

Page 381: ... Instruction manual 381 ...

Page 382: ... TPD32 EV 382 ...

Page 383: ... Instruction manual 383 ...

Page 384: ... TPD32 EV 384 ...

Page 385: ... Instruction manual 385 ...

Page 386: ... TPD32 EV 386 ...

Page 387: ... Instruction manual 387 ...

Page 388: ... TPD32 EV 388 ...

Page 389: ... Instruction manual 389 ...

Page 390: ... TPD32 EV 390 ...

Page 391: ... Instruction manual 391 ...

Page 392: ... TPD32 EV 392 ...

Page 393: ... Instruction manual 393 ...

Page 394: ... TPD32 EV 394 ...

Page 395: ... Instruction manual 395 ...

Page 396: ... TPD32 EV 396 ...

Page 397: ... Instruction manual 397 ...

Page 398: ... TPD32 EV 398 ...

Page 399: ... Instruction manual 399 ...

Page 400: ... TPD32 EV 400 ...

Page 401: ... Instruction manual 401 ...

Page 402: ... TPD32 EV 402 ...

Page 501: ... Instruction manual 501 APPENDIX 3 ACCESSORIES A3 1 EAM Adapter Kit EAM1579 EAM1580 ...

Page 503: ......