ELECTRICAL— BODY AND CHASSIS 12-17

7. Remove mast jacket upper bracket.

bearing housing, switch cover and shift housing from

8. Remove switch wiring cover from column.

column.

9. Remove switch mounting screws and remove switch,

10. To install, reverse removal procedure.

WINDSHIELD WIPER AND WASHER

INDEX

Page

Page

W in d sh ie ld W ash er P u m p A s s e m b l y .................................... ...12-19

R e m o v a l - I n s t a l l a t i o n ................................................................12-19

D is a s s e m b ly - A s s e m b l y ..........................................................12-20

GENERAL DESCRIPTION

The type “ E " two-speed electric windshield wiper

assembly incorporates a non-depressed type (blades park

approximately

2”

above windshield molding) motor and

gear train. The rectangular, 12 volt, compound wound

motor is coupled to a train consisting of a helical drive

gear at the end of the motor armature shaft, an intermediate

gear and pinion assembly, and an output gear and shaft

assembly. The crank arm is attached to the output gear

shaft. Depending on the wiring harness of the different

trucks, the wiper motors are equipped with three or four

terminals. For service replacement a four terminal as

sembly is used, servicing both, the three terminal and the

four terminal models.

Two switches, connected in parallel, control the start

ing, stopping and parking of the Type “ E” wiper motor.

The manually operated start, stop switch is located on the

instrument panel, while the cam operated park switch is

located in the wiper gear box.

SERVICE OPERATIONS

WIPER M OTOR DISASSEMBLY

Gear Box

WIPER MOTOR

REM OVAL A N D INSTALLATION

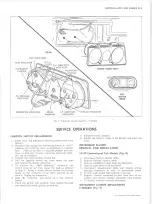

10-30 Conventional Cab Models (Fig. 16)

1. Disconnect battery ground cable.

2. Remove wiper arms and blades from transmission

shaft.

3. Remove plenum chamber grille.

4. Disconnect wiper drive rods from crank arm; re

move crank arm nut and arm from motor shaft.

5. Working under instrument console, disconnect wiper

motor and washer wiring connectors.

NOTE:

If vehicle is equipped with a parking

brake assembly located on the vertical sur

face of the cowl front panel (directly below the

wiper motor) remove the parking brake as

sembly attaching bolts (4) to allow shifting of

the assembly rearwards in order to provide

access for removal and installation of the wiper

motor assembly.

Disconnect and remove left-hand defroster hose.

6. Disconnect washer hoses from washer pump.

7. Remove motor attaching screws and motor from cowl

mounting position.

8. To install, reverse removal procedures.

NOTE:

Make certain wiper motor and blades

are in the "P ark" position.

Refer to Figure 17.

1. Remove the two washer pump mounting screws and

lift pump off washer.

2. Remove washer pump drive cam as required (fig.

21, 22). The cam is pressed on the shaft but can be

wedged off by using two screw drivers between cam

and plate.

3. Clamp crank arm in a vise and remove crank arm

retaining nut.

CAUTION:

Failure to clamp crank arm may re

sult in stripping of wiper gears!

4. Remove crank arm, seal cap, Tru-Arc retaining ring,

and end-play washers.

NOTE:

Seal cap should be cleaned and re

packed with a water-proof grease before re

assembly.

5. Drill out gear box cover retaining rivets, remove

cover from gear train.

NOTE:

Screws, nuts and lock washers for re

assembling cover to wiper are contained in a

service repair package.

6. Remove output gear and shaft assembly, then slide

intermediate gear and pinion assembly off shaft.

7. If necessary, remove terminal board and park switch

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......