BRAKES 5-5

R E A R A X L E

B R A K E H O S E

FUEL LIN E

R E A R B R A K E

F R O N T PIPE

FWD

Fig. 9— Brake Line Retainers - T/pical

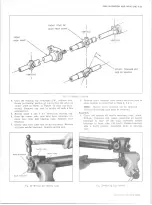

Hydraulic Brake Tubing (Figs. 10 thru 14)

Hydraulic brake tubing used on all trucks is a double

layer flexible steel, copper coated and tin plated tubing

which resists corrosion and also stands up under the high

pressures which are developed when applying the brakes.

In making up hydraulic brake pipes, it is important that

the ends of the tubing be flared properly for the compres

sion couplings. Unless the tubing is properly flared, the

couplings will leak and the brakes will become ineffective.

This safety steel tubing must be double-lap flared at

the ends in order to produce a strong leak-proof joint.

The Tool J-2185 must be equipped with the proper size

die block and upset flare punch for each size tubing to

form the double-lap flare.

The proper size die blocks and upset flare punches are

as follows:

Upset

Finish

Flare Punch

Flare Punch

Tubing Size

Die Block

3/16'

1/4'

5/16'

J-2185-27

J-2185-28

J-2185-29

J-2185-3

J-2185-37

J-2185-4

J-2185-26

J-2185-26

J-2185-26

Fig. 10— Tubing Flaring Tool J-2 185

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......