ENGINE-ELECTRICAL 6Y-16

NOTE:

The contact point pressure must fall

within specified limits. Weak tension will cause

chatter resulting in arching and burning of the

points and an ignition miss at high speed, while

excessive tension will cause undue wear of the

contact points, cam and rubbing block. Breaker

arm spring tension should be 19-23 ounces. The

contact point pressure should be checked with a

spring gauge. The scale should be hooked to the

breaker lever and the pull exerted at 90 degrees

to the breaker lever as shown in Figure 2i. The

reading should be taken just as the points sepa

rate. The pressure can be adjusted by bending

the breaker lever spring. If the pressure is

excessive, it can be decreased by pinching the

spring carefully. To increase pressure, the lever

must be removed from the distributor so the

spring can be bent away from the lever. Avoid

excessive spring distortion.

9. Set point opening (.019" for new points).

10. Reinstall dust shield, rotor, position and lock distri

butor cap to housing.

11. Start engine and test dwell and ignition timing.

Eight Cylinder Engine Distributor

1. The contact point set is replaced as one complete

assembly and only dwell angle requires adjustment

after replacement. Breaker leaver spring tension and

point alignment are factory set.

2. Remove the distributor cap by placing a screw driver

in the slot head of the latach, press down and turn

1/4 turn in either direction.

3. Remove the two attaching screws which hold the base

of the contact set assembly in place.

4. Remove the primary and condenser leads from their

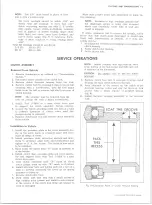

nylon insulated connection (fig. 3i) in contact set.

5. Reverse Steps 2, 3 and 4 to install new contact set.

CAUTION:

install the primary and condenser

leads as shown in Figure 3i. Improper installa

tion will cause lead interference between the cap,

weight base and breaker advance plate.

6. If vehicle has 20,000 to 25,000 miles (or sooner if

desired) the cam lubricator wick (fig. 4i) should be

changed. Using long nosed pliers squeeze assembly

together at base and lift out. Remove all old lubri

cant from cam surface. Replace in same manner.

NOTE:

End of cam lubricant wick should be

adjusted to just touch cam lobes. Over lubrica

tion of cam resulting in grease on contact points

can be caused by cam lubrication wick bearing

too hard against cam surface. A correctly ad

justed cam lubricator wick will provide adequate

lubrication for cam. Do not apply additional

grease to cam surface.

7. Start engine and check point dwell and ignition timing.

Setting Dwell Angle

Six Cylinder Engine Distributor

The point opening of new points can be checked with a

feeeler gauge, but the use of a feeler gauge on rough or

uncleaned used points is not recommended since accurate

mechanical gauging cannot be done on such points (fig 6i).

Contacts points must be set to the proper opening.

Points set too close may tend to burn and pit rapidly.

Points with excessive separation tend to cause a weak

spark at high speed. Proper point setting for all models

are:

.019" for new points

.016" for used points

New points must be set to the larger opening as the

rubbing block will wear down slightly while seating to the

cam. Contact points should be cleaned before adjusting if

they have been in service.

To adjust the contact point opening:

1. If necessary, align points (fig. 6i) by bending the fixed

contact support. Do not bend the breaker lever. Do

not attempt to align used points; replace them where

serious misalignment is observed. Use an aligning

tool if available.

2. Turn or crank the distributor shaft until the breaker

Fig. 2 i-C h e c k in g Breaker Arm Spring Tension

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......