ELECTRICAL— BODY AND CHASSIS 12-3

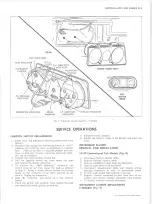

Fig. 2— Headlamp Adjustment's

2. Remove lamp housing retaining nuts, and disengage

assembly from grille or panel opening.

3. Disconnect parking lamp wiring from forward wiring

harness.

4. Connect wiring of new unit to vehicle harness.

5. Position lamp housing in grille or panel opening, as

appropriate and install retaining nuts.

6. Install bulb, lens and bezel as required.

CLEARANCE A N D IDENTIFICATION LAMP

H O U SIN G REPLACEMENT (See Fig. 4)

REAR LIGHTING (Fig. 5)

Exploded views of the different rear lighting arrange

ments are shown in Figure 5. The bulbs may be replaced

by removing the lamp lens attaching screws and lamp

lens. The lamp housings may be replaced by removing

the housing attaching nuts or screws, or by removing

the nuts and bolts from the bracket.

M ARKER LAMPS (Fig. 5)

1. Remove screws retaining marker lamp assembly to

sheet metal or housing.

NOTE:

Lamp assembly lens does not separate

from back.

2. Rotate marker lamp assembly over and turn plug

connector 1/4 turn counter-clockwise to remove and

replace bulb inset in plug connector.

DIRECTIONAL SIG NAL LAMPS

Directional Signal lights are an integral part of the

parking and taillight assemblies.

NOTE:

On vehicles using parking and taillight

assemblies for directional signals, refer to ap

plicable light assemblies for bulb replacement.

Bulb Replacement (Cab Mounted Directional Lamps)

1. Remove three screws which retain rear lens to lamp

assembly and remove lens.

2. Replace bulb and check operation of lamp.

3. Position lens and install attaching screws.

WIPER SWITCH REPLACEMENT (Fig. 8)

1. Disconnect battery ground cable.

2. Loosen set screw and remove wiper knob.

3. Remove bezel and retaining nut.

4. Push switch from panel opening and remove from

behind instrument cluster.

5. Disconnect wiring at switch terminals.

6. To install, reverse removal procedure and check

operation of unit.

LIGHT SWITCH REPLACEMENT (Fig. 8)

1. Disconnect battery ground cable.

2. Reaching up behind instrument cluster, depress shaft

retaining button and remove switch knob and rod.

3. Remove bezel and retaining nut.

4. Push switch from panel opening and remove from

behind instrument panel.

5. Disconnect multiple wiring connectors at switch

terminals.

6. To install, reverse removal procedure.

STOPLIGHT SWITCH REPLACEMENT

Conventional Cab Models (Fig. 6)

1. Disconnect wiring harness connector from switch and

remove switch retaining nut.

2. Depress brake pedal and place new switch into

bracket and install retaining nut.

3. Check switch for proper operation. Electrical contact

should be made when pedal is depressed 3/8” to 5/8”

from fully released position.

DIM M ER SWITCH REPLACEMENT

1. Fold back upper left corner of the floor mat and re

move two screws retaining switch to the toe pan.

2. Disconnect wiring connector from switch terminals.

3. Connect wiring to replacement switch and check

operation.

4. Position switch to toe pan and install retaining

screws.

5. Replace floor mat.

NEUTRAL SAFETY SWITCH REPLACEMENT

Column Shift— Switch Located on M ast Jacket

1. Disconnect wiring harness connectors at switch ter

minals.

2. Remove switch retaining screws and switch from mast

jacket.

3. To install, position shift lever in drive and locate

lever tang against transmission selector plate.

4. Align slot in contact support with hole in switch and

insert pin (3/32” dia.) to hold support in place.

Switch is now in drive position.

5. Place contact support drive slot over shifter tube

drive tang and tighten screws. Remove clamp and

pin.

6. Connect wiring harness to terminals and check

operation of switch.

Column Shift— Switch Located on Transmission

(Fig. 7)

1. Raise and support vehicle.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......