HEATER AND AIR CONDITIONING 1A-22

REFRIGERANT QUICK-CHECK PROCEDURE

The following procedure can be used to quickly de

termine whether or not an air conditioning system

has a proper charge of refrigerant. This check can be

made in a manner of minutes thus facilitating system

diagnosis by pinpointing the problem to the amount of

charge in the system or by eliminating this possibility

from the overall checkout.

Start engine and place on fast idle. Set

controls for maximum cold with blower on high.

Bubbles present in sight No bubbles. Sight glass

glass.

clear.

System low ' on charge.

Check with leak detector.

Correct leak, if any, and

fill system

to proper

charge.

System is

either fully

charged or empty. Feel

high and low pressure

pipes

at

compressor.

High pressure pipe should

be warm; low pressure

pipe should be cold.

I

No appreciable tempera

ture differential noted at

compressor.

I

System empty or nearly

empty. Turn off engine

and connect charging sta

tion. Induce 1/2# of re

frigerant in system (if

system will not accept

charge, start engine and

draw 1/2# in through low

pressure

side).

Check

system with leak detector.

Temperature differential

noted at compressor.

Even though a differential

is noted, there exists a

possibility of overcharge.

An overfilled system will

result in poor cooling dur

ing low speed operation

(as a result of excessive

head pressure). An over

fill is easily checked by

disconnecting the com

pressor clutch connector

while observing the sight

glass.

If refrigerant in sight

glass remains clear for

more than 45 seconds (be

fore foaming and then set

tling away from

sight

glass) an overcharge is

indicated. Verify with a

performance check.

If refrigerant foams and

then settles away from

sight glass in less than 45

seconds, it can be as

sumed that there is a

proper charge of refriger

ant in system.

Continue

checking out system using

performance checks out

lined previously.

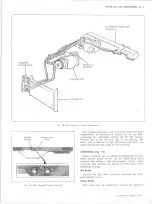

under “ Purging the System.” Refer to Figure 30

while performing the following operation.

2. After system has been purged, connect the vacuum

line to the vacuum pump, turn on pump and open

Vacuum Control Valve (3) - See "General Note"

under "Evacuating and Charging the System." Con

tinue to run pump for 15 minutes after the system

reaches 28-29 inches vacuum.

NOTE:

If 28-29 inches cannot be obtained,

close Vacuum Control Valve (3) and shut off

vacuum pump. Open Refrigerant Control Valve

(4) and allow 1/2 pound of R-12 to enter system.

Locate and repair all leaks.

Purge this 1/2

pound and re-evacuate for 5 minutes.

3. Only after evacuating as above, is system ready for

charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, fill to the proper level.

4. With High and Low pressure Valves (1 and 2)

open, close Vacuum Control Valve (3) and open

Refrigerant Control Valve (4).

NOTE:

If the charge will not transfer com

pletely from the station to the system, close

the high pressure valve at the gauge set, set

the air conditioning controls for cooling, check

that the engine compartment is clear of ob

structions, and start the engine. Compressor

operation will decrease the low side pressure

in the system.

System is now charged and should be performance

tested before removing gauges.

CHECKING OIL

In the six cylinder compressor it is not recommended

that the oil be checked as a matter of course. Generally,

compressor oil level should be checked only where

there is evidence of a major loss of system oil such as

might be caused by:

• A broken refrigerant hose.

• A severe hose fitting leak.

• A very badly leaking compressor seal.

• Collision damage to the system components.

As a quick check on compressor oil charge, with the

engine off, carefully crack open the oil drain plug on the

bottom of the compressor. If oil comes out, the com

pressor has the required amount of oil. To further check

the compressor oil charge, should the above test show

insufficient oil, it is necessary to remove the compressor

from the vehicle, drain and measure the oil.

NOTE:

The oil may appear foamy. This is con

sidered normal.

To further check the compressor oil charge, should the

above test show insufficient oil, it is necessary to remove

the compressor from the vehicle, drain and measure

the oil as outlined under “ Checking Compressor Oil

Charge/'

Checking Compressor Oil Charge

1. Run the system for 10 minutes at 500-600 engine

rpm with controls set for maximum cooling and high

blower speed.

2. Turn off engine, discharge the system, remove

compressor from vehicle, place it in a horizontal

position with the drain plug downward. Remove the

drain plug and, tipping the compressor back and

forth and rotating the compressor shaft, drain the

oil into a clean container, measure and discard the

oil.

3. a. If the quantity drained was 4 fluid oz. or more,

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......