SECTIO N 12

ELECTRICAL—BODY AND CHASSIS

CONTENTS OF THIS SECTION

Page

L ig h tin g S y s t e m ...................................................................................... 12-1

In s tru m e n ts and G auges . . . ..............................................................12-8

D ire c tio n a l S i g n a l s ............................................................................ ....12-16

W in d sh ie ld W ip e r and W a s h e r ....................................................... ... 12-17

LIGHTING SYSTEM

INDEX

Page

Sealed B e am U nit R e p la c e m e n t.................................................... 12-2

P a rk in g L a m p R e p la c e m e n t .......................................................... 12-2

R e a r L i g h t i n g ......................................................................................12-3

Page

M a rk e r, C le aran ce and Id e n tific a tio n ...........................................12-3

D ire c tio n a l Signal L a m p s ............................................................. ...12-3

W ip e r Switch R e p la c e m e n t................................................................12-3

L ig h t Switch R e p la c e m e n t ............................................................. ...12-3

N e u tra l Safety Switch R e p la c e m e n t ..............................................12-3

B acking L a m p Switch R e p l a c e m e n t ..............................................12-7

GENERAL DESCRIPTION

The lighting system includes the main light switch;

stop light, dimmer and backing lamp switches; head and

parking lamps; stop, tail, side marker, clearance and

identification lamps; instrument illumination, directional

signal and indicator lamps and the necessary wiring to

complete the various circuits.

A bulkhead fuse panel (fig. 1) provides convenient power

taps and fuse clips for the appropriate curcuits. The

engine wiring harness and forward lamp harness con

nectors are bolted to the fuse panel.

All wiring systems not protected by fuses incorporate

a fusible link which provides increased overload protec

tion. The starting motor circuit is the exception.

Composite wiring diagrams are included at the end of

this section. The standardized color code is common to

all wiring harnesses. The wire covering color designates

a particular circuit usage.

M AIN TEN AN CE A N D ADJUSTMENTS

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head

lamps are properly adjusted. Loose or corroded connec

tions may cause a discharged battery, difficult starting,

dim lights, and possible damage to generator and regulator.

Wire harnesses must be replaced if insulation becomes

burned, cracked, or deteriorated. Whenever it is neces

sary to splice a wire or repair one that is broken, always

use solder to bond the splice. Always use rosin flux

solder on electrical connections. Use insulating tape to

cover all splices or bare wires.

When replacing wires, it is important that the correct

size by used. Never replace a wire with one of a smaller

size. Fusible links in the Chevrolet wiring are four

gauge sizes smaller than the cable it is designed to pro

tect. The links are marked on the insulation with wire

gauge size because of the heavy insulation which makes

the link appear a heavier gauge than it actually is.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

wearing away the insulation due to vibration.

By referring to the wiring diagrams, circuits may be

tested for continuous circuit or shorts with a conventional

test lamp or low reading volt meter.

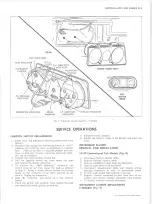

HEADLAMP ADJUSTMENT— T-3 HEADLAMP (Fig. 2)

Headlamp Aiming

The headlamps must be properly aimed to obtain maxi

mum road illumination.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......