REAR SUSPENSION AND DRIVE LINE 4-16

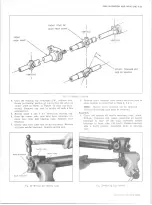

Fig. 30— A xle Vent Installation

2. Connect and secure shock absorbers to axle

brackets.

3. Connect hydraulic brake hose to connector on axle

housing, and bleed hydraulic system as specified in

Section 5. (If vehicle is equipped with air brakes,

connect air line at brake chambers--test connections

to make sure that there is no leakage.)

4. Connect hand brake cables and adjust parking brakes

as specified in Section 5.

5. Reassemble the rear universal joint, making sure

that "U ” bolts are drawn up tight and locked prop

erly. Caution should be taken not to overtighten

bolt nuts and cause bearing cups to become distorted.

6. Install rear wheels, remove stand jacks, and lower

vehicle.

7. Test operation of brakes and rear axle.

3.

Thoroughly clean both the axle shaft flange and the

end of the wheel hub.

NOTE:

Any lubricant on these surfaces tends

to loosen axle shaft flange bolts.

4.

Place a new gasket over the axle shaft and position

the axle shaft in the housing so that the shaft splines

enter the differential side gear. Position gasket so

that holes are in alignment and install flange-to-hub

attaching bolts--torque bolts to specifications.

NOTE:

To prevent lubricant from leaking

through flange holes, apply a non-hardening

sealer (such as Permatex Type A or equivalent)

to bolt threads. Use care in the amount of sealer

applied, as in too heavy an application, the

sealer may be forced out as the bolt is installed

and may destroy sealing effect of the flange-to-

hub gasket.

AXLE SHAFT 11,000 LB. AXLES

AXLE VENT

Replacement

Service replacement axle housing assemblies are not

equipped with an axle vent; therefore, always make sure

that a new vent assembly is installed when replacing the

housing. If axle vent requires replacement, pry old vent

from housing being sure that entire vent is removed.

Prick punch around carrier hole to insure fit of replace

ment vent. Tap new vent into housing using a soft-faced

hammer. Vent should be positioned in housing so that

flat surface is toward centerline of differential carrier

(fig. 30).

AXLE SHAFT (EXCEPT 11,000 LB. AXLE)

Removal and Installation

1. Remove bolts and lock washers that attach the axle

shaft flange to the wheel hub.

2. Install two 1/2"-13 bolts in the threaded holes pro

vided in the axle shaft flange. By turning these bolts

alternately the axle shaft may be easily started and

then removed from the housing (fig. 31).

Fig. 32— Removing A xle Shaft (11,000 lb. A xle )

10-30 CHEVROLET TRUCK SERVICE MANUAL

Fig. 31.— Removing A xle Shaft (5200 and 7200 lb. Axle)

Removal and Installation

1. Remove hub cap, and install Tool J-8117 in tapped

hole on shaft flange.

2. Install slide hammer (Tool J-2619) and remove axle

shaft (fig. 32).

3. Thoroughly remove old gasket material from hub and

hub cap. Clean shaft flange and mating surfaces in

the wheel hub.

4. Install axle shaft so that the flange splines index into

hub splines. Tap shaft into position, using J-8117

and J-2619.

5. Install new hub cap-to-hub gasket, position hub cap to

hub and install attaching bolts--torque bolts to

specifications.

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......