REAR SUSPENSION AND DRIVE LINE 4-15

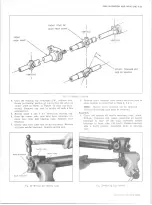

Fig. 28— Pinion Flange Installation

it could affect the performance of vital compo

nents and systems, and/or could result in major

repair expense. It must be replaced with one of

the same part number or with an equivalent

part if replacement becomes necessary. Do not

use a replacement part of lesser quality or

substitute design. Torque values must be used

as specified during reassembly to assure proper

retention of this part.

16. Lower vehicle and remove from hoist.

POSITRACTION DIFFERENTIAL UNIT

The optionally available Positraction differential unit

is installed in the conventional carrier to replace the

standard differential unit.

Service procedures for the Positraction equipped axle

are the same as on a conventional axle except for the "on

the vehicle check” .

On-the-Vehicle Check

If vehicle is equipped with a manual transmission,

shift transmission into neutral.

1. Raise rear of vehicle until wheels are off the ground,

remove one wheel and tire assembly.

2. Attach Adapter J-5748 to axle shaft flange and install

a 1 / 2 1 3 bolt into adapter (fig. 29).

3. With wheel and tire assembly still on vehicle held

firmly to prevent turning, measure torque required

to rotate opposite axle shaft with a 0-150 lb. torque

wrench attached to J-5748. For all except Dana

torque should be 70 ft. lbs. minimum new, and no

less than 40 ft. lbs. if used. Dana axles torque

should be at least 40 ft. lbs. but no more than 200

ft. lbs.

5200 11,000 LB. CAPACITY AXLE

NOTE:

Because Series 20, 5500 lb. Capacity

Dana Salisbury axles are full floating axles,

their service procedures are a combination of

Series 10 Salisbury axle procedures and Series

20-30, 5200, 5500 lb. capacity axle service pro

cedures. Consequently, refer to Series 10, 3300

and 3500 lb. capacity axle service procedures

for service on the differential such as pinion

shaft oil seal and companion flange and to Series

20-30, 5200 - 7200 lb. capacity axles service

procedures for service on wheel hubs, bearings,

and axle shafts.

Axle Assembly

Service operations on these axle assemblies may be

performed with the housing installed in the vehicle or

with the housing installed in a holding fixture. There may

be occasions, however, when it will be necessary to re

move the complete housing assembly. The following axle

assembly removal and installation procedure, therefore,

is necessary only when housing replacement is required.

NOTE:

All axle attachments are important at

taching parts in that they could affect the per

formance of vital components and systems,

and/or could result in major repair expense.

They must be replaced with parts of the same

part numbers or with equivalent parts if re

placement becomes n e c e s s a r y . Do not use

replacement parts of lesser quality or substitute

design. Torque values must be used as specified

during reassembly to assure proper retention of

these parts.

Removal

1. Raise vehicle, place stand jacks under frame side

rails, and remove rear wheels.

2. Remove two trunnion bearings

“ XJ”

bolts from the

rear yoke, split rear universal joint, position propel

ler shaft to one side, and tie it to the frame side rail.

NOTE:

The bearings can be left on the trunnion

and held in place with tape.

3. Remove brake drum and disconnect parking brake

cable at lever and at flange plate. (See Section 5 for

cable removal.)

4. Disconnect hydraulic brake hose at connector on rear

axle housing. (Refer to Section 5)

5. Disconnect shock absorbers at axle brackets.

6. Support axle assembly with hydraulic jack, remove

spring

“ \J”

bolts, and lower axle assembly to the

floor.

Installation

1. Place axle assembly under vehicle, raise into posi

tion, install spring <fU” bolts, anchor plates and

nuts, and tighten securely. (On P30 series vehicles

make sure that stabilizer anchor plates are properly

positioned on forward “ U” bolts.)

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......