HEATER AND AIR CONDITIONING 1A-15

• A five ampere time delay cartridge fuse has been

installed in the common line to protect the windings

of the compressor.

The fuse will blow if an ex

cessive load is placed on the pump. In the event the

fuse is blown, replace with a five ampere time delay

fuse - do not use a substitute fuse as it will result in

damage to the starting windings.

• If the pump is being utilized to evacuate a burnt-out

system, a filter must be connected to the intake

fitting to prevent any sludge from contaminating the

working parts, which will result in malfunction of the

pump.

• Do not use the vacuum pump as an air compressor.

LEAK TESTING THE SYSTEM

Whenever a refrigerant leak is suspected in the system

or a service operation performed which results in dis

turbing lines or connections, it is advisable to test for

leaks. Common sense should be the governing factor in

performing any leak test, since the necessity and extent

of any such test will, in general, depend upon the nature

of the complaint and the type of service performed on the

system.

NOTE:

The use of a leak detecting dye within

the system is not recommended because of the

following reasons:

1. Refrigerant leakage can exist without any oil leakage.

In this case the dye will not indicate the leak, how

ever, a torch detector will.

2. The addition of additives, other than inhibitors, may

alter the stability of the refrigeration system and

cause malfunctions.

3. Dye type leak detectors, which are insoluble, form a

curdle which can block the inlet screen of the ex

pansion valve.

Leak Detector

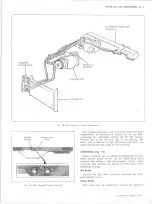

Tool J-6084 (fig. 24) is a propane gas-burning torch

which is used to locate a leak in any part of the system.

Refrigerant gas drawn into the sampling tube attached to

the torch will cause the torch flame to change color in

proportion to the size of the leak.

Propane gas fuel

cylinders used with the torch are readily available com

mercially throughout the country.

CAUTION:

Do not use lighted detector in any

place where combustible or explosive gases,

dusts or vapors may be present.

Operating Detector

1. Determine if there is sufficient refrigerant in the

system for leak testing.

2. Open control valve only until a low hiss of gas is

heard, then light gas at opening in chimney.

3. Adjust flame until desired volume is obtained. This

is most satisfactory when blue flame is approxi

mately 3/8” above reactor plate. The reactor plate

will quickly heat to a cherry red.

4. Explore for leaks by moving the end of the sampling

hose around possible leak points in the system. Do

not pinch or kink hose.

NOTE:

Since R-12 is heavier than air, it is

good practice to place open end of sampling tube

Fig. 24—-Leak Detector

immediately below point being tested, particu

larly in cases of small leaks.

CAUTION:

Do_ not breathe the fumes that are

produced by the burning R-12 gas in the de

tector flame, since such fumes can be toxic in

large concentrations of R-12.

5. Watch for color changes.

The color of the flame

which passes through the reaction plate will change

to green or yellow-green when sampling hose draws

in very small leaks of R-12. Large leaks will be

indicated by a change in color to a brilliant blue or

purple. When the sampling hose passes the leak,

the flame will clear to an almost colorless pale

blue again. Observations are best made in a semi

darkened area. If the flame remains yellow when

unit is removed from leak, insufficient air is being

drawn in or the reactor plate is dirty.

NOTE:

A refrigerant leak in the high pressure

side of the system may be more easily detected

if the system is operated for a few minutes,

then shut off and checked immediately (before

system pressures equalize). A leak on the low

pressure side may be more easily detected after

the engine has been shut off for several minutes

(system pressures equalized); this applies par

ticularly to the front seal.

AVAILABILITY OF REFRIGERANT-12

Refrigerant 12 is available in 30 lb. and in 15 oz. dis

posable containers.

Normally, air conditioning systems are charged making

use of the J-8393 Charging Station which uses the 30 lb-

container.

Evacuating and Charging Procedures are

noted later in this section.

The 15 oz. disposable cans are generally used for

miscellaneous operations such as flushing.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......