ENGINE-ELECTRICAL 6Y-18

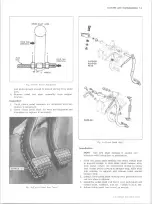

LATERAL

PROPER

MISALIGNMENT

LATERAL ALIGNMENT

CORRECT LATERAL MISALIGNM ENT BY

BENDING FIXED CONTACT SU PPO RT

N E V E R BEND B R E A K E R L E V E R

Fig. 6i-A lignm ent of Points

b. Rotate the shaft until one of the circuit breaker

cam lobes is under the center of the rubbing block

of the breaker lever.

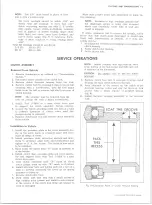

c. Turn the adjusting screw clockwise (fig. 8i) until

the lamp lights, then give the wrench 1/2 turn in

the opposite direction (counterclockwise) to obtain

the proper dwell angle.

DISTRIBUTOR CONDENSER

Performance Diagnosis

The following four factors affect condenser perfor

mance, and each factor must be considered in making

any condenser test.

1. Breakdown - A failure of the insulating material. A

direct short between the metallic elements of the

condenser. This prevents any condenser action.

2. Low Insulating Resistance (leakage) - Low insulation

resistance prevents the condenser from holding a

charge. All condensers are subject to leakage which,

up to a certain limit, is not objectionable.

3. High Series Resistance - Excessive resistance in the

condenser circuit due to broken strands in the con-

Fig. 7i — Setting Point O pening

denser lead or to a defective connection. This will

casue burned points and ignition failure upon intial

starts and at high speeds.

4. Capacity - Capacity is determined by the area of

the metallic elements and the insulating and impreg

nating materials.

For a complete check of the condenser, use a tester

which will check for all of the above conditions. Follow

the instructions given by the manufacturer of the test

equipment. Condenser capacity should be .18-.23 micro

farads.

Replacement

Six Cylinder Engine Distributor (Fig. 1 i)

1. Release distributor cap hold-down screws, remove

cap and place it out of the work area.

2. Remove rotor and dust shield.

3. Disconnect condenser lead wire from contact point

quick-disconnect terminal.

4. Remove condenser attaching screw, lift condenser

from breaker plate and wipe breaker plate clean.

5. Install new condenser using reverse of procedure

outlined above.

Eight Cylinder Engine Distributor

1. Remove distributor cap.

2. Loosen condenser lead attaching screw (fig. 3i) and

lift out condenser lead clip.

3. Remove screw holding condenser bracket to breaker

plate and slide condenser from bracket.

4. To replace condenser reverse the above procedure.

NOTE:

Make sure that new condenser lead is

installed in proper position (fig. 5i).

DISTRIBUTOR— Removal

1. Release the distributor cap hold-down screws, re

move the cap and place it clear of the work area.

NOTE:

If necessary, remove secondary leads

from the distributor cap after first marking the

cap tower for the lead to No. 1 cylinder. This

will aid in the reinstallation of leads in the cap.

2. Disconnect the distributor primary lead from the

coil terminal.

Fig. 8 i-A d ju stin g Dwell A n gle

W INDOW

"H EX” TYPE

ADJUSTING

SCREW

10-30 CHEVROLET TRUCK SERVICE MANUAL

Summary of Contents for 10 1971 Series

Page 1: ......

Page 96: ......

Page 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Page 120: ......

Page 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 218: ......

Page 249: ......

Page 324: ......

Page 340: ......

Page 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Page 368: ......

Page 386: ......

Page 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 391: ......

Page 428: ......

Page 432: ......

Page 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Page 463: ......

Page 464: ......

Page 465: ......

Page 466: ......