66 Electrical design and installation

Manual Energy Storage Inverter ESI-S

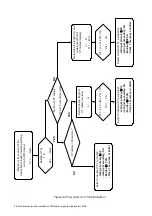

In a multi-master arrangement, the master that has the control over the system (i.e. the

master which is operational and which has the lowest address) will monitor the digital

inputs. Therefore, in order to obtain full redundancy with inverters consisting of more

than one master unit, the digital inputs of all the units in a multi-master arrangement

have to be set up and cabled in the same way.

Remarks:

−

When the remote control functionality has been activated this function has

priority over a local start/stop command. When the local command has to be

given, deactivate first the remote control functionality by navigating with the

ESI-Manager to the digital input setup menu and setting the digital input

considered to ‘Disabled’.

−

The remote control functionality can also be implemented on the Digital Input 2.

6.14.2 Cabling of alarm functionality

An alarm represents an error condition that makes the inverter trip.

Two types of error conditions exist:

1. External error condition: These are conditions that are imposed on to the inverter

from the outside world. Consider the example of the network voltage that increases

well above the inverter safe operation level for a certain time. In that case the inverter

will disconnect from the network reporting a network over voltage. When the

network voltage returns to a normal level however, the inverter will reconnect to the

network and continue filtering providing that the same problem does not occur

systematically.

2. Internal error conditions: These are error conditions that are reported by internal

controls of the inverter itself. They may indicate an internal inverter problem.

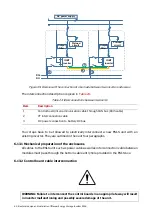

Two ways to cable the alarm functionality exist:

1. The ESI-Manager alarm outputs located at the bottom right side (when looking at the

ESI-Manager from the rear) are triggered (return to default position) whenever:

−

A permanent internal or external error condition is present. In order to avoid

transient switching of the contacts, the error has to be present for 3 minutes

before the alarm relays are activated.

−

No power is supplied to the inverter

further down this section gives an overview of all the error conditions that lead

to the alarm contact being triggered. Two alarm contacts exist, one being of type

‘normally open’ (NO) and the other of type ‘normally closed’ (NC).

The alarm contacts are

−

Free of potential

−

Rated for a maximum of 250 Vac/1.5 A or 30 Vdc/5 A. When using a

24 Vdc power supply, a minimum current of 25 mA should be drawn by the circuit

connected to the alarm contact.