72

2.

C input: input the relative coordinate to the length compensation H where the cursor located, the cursor

is not available in other columns.

3.

Clear: clear tool compensation and wear values of all numbers and set to 0.

4.

Zero: the location of the cursor is set to the value of 0.

5.

+input: add the value of the location of the cursor with the values in the input box.

6.

Input: set the value of the position of cursor to the value of the input box, the shortcut button is INPUT.

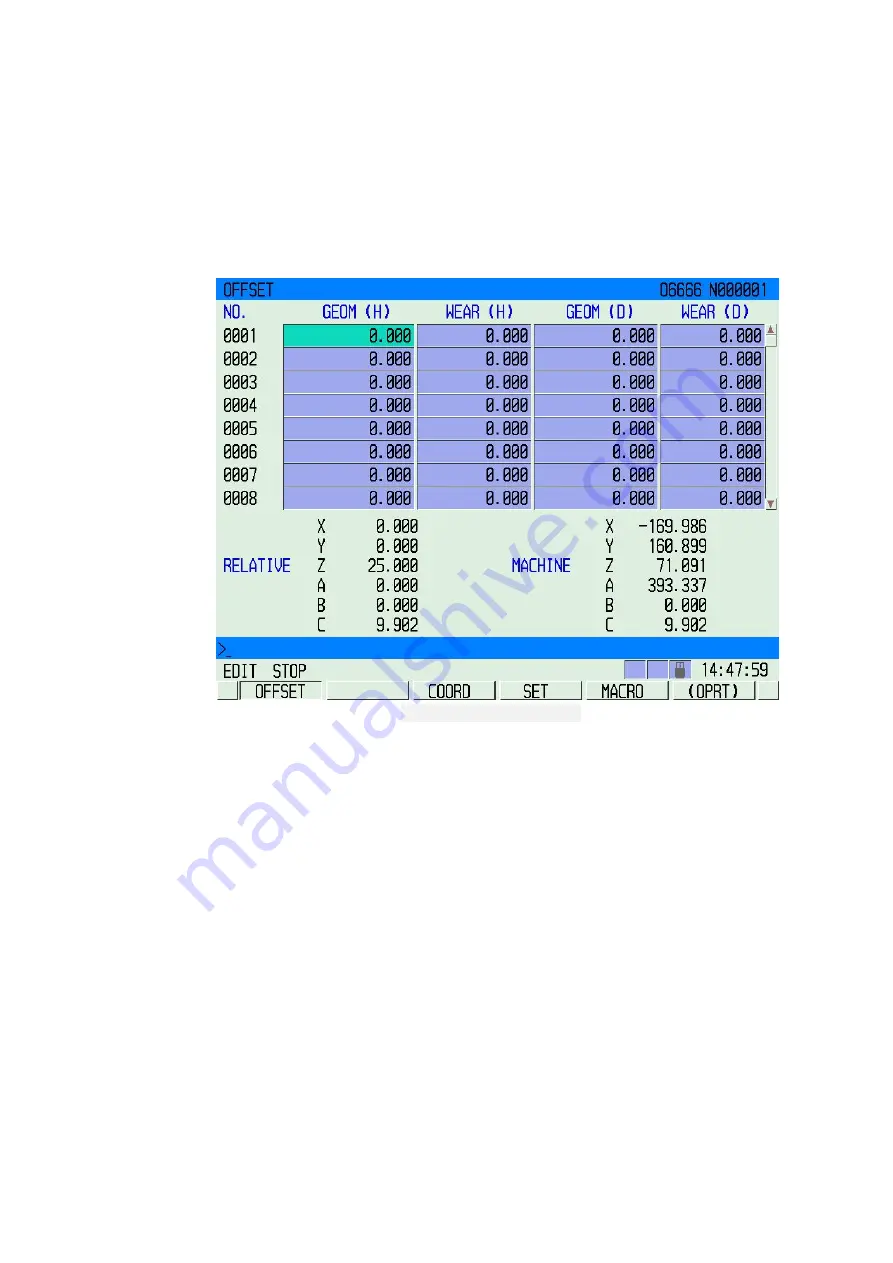

Fig.3-12

Coordinate System Interface

3.7.2 Tool Compensation Amount Modification

1.

1)

Select the shape / wear compensation

2)

For the display is divided into multiple pages, press the page button and select the desired page.

3)

Move the cursor to the location of the entering offset number

Scanning method: press the Up and Down cursor button to move the cursor in sequence

Searching Method: using the following key sequence to move the cursor directly to the typed position:

compensation number → [ SRH].

2.

Incremental input

1)

Move the cursor to the location of the entering offset number

2)

Input the incremental value by using the data button.

3)

Press button [INPUT] to add the current compensation amount and the type amount, the result can be

displayed as the new compensation amount.

Example: the current compensation amount 5.678

Keyboard input increment 1.5

The new compensation amount 7.178(=5.678+1.5)

3.

C Input

1)

Select No.1 tool as the reference tool knife and aligning tool in the surface.

2)

Input Z0 in the coordinate system and press [measure] to determine the values of coordinates Z axis.