13.1 Overview of Troubleshooting

13-3

13

13.1.2 Basic Troubleshooting Flow

When a problem occurs, it is important to determine the cause and treat the problem fast to get the system up and

running as quickly as possible. The following table shows the basic troubleshooting flow.

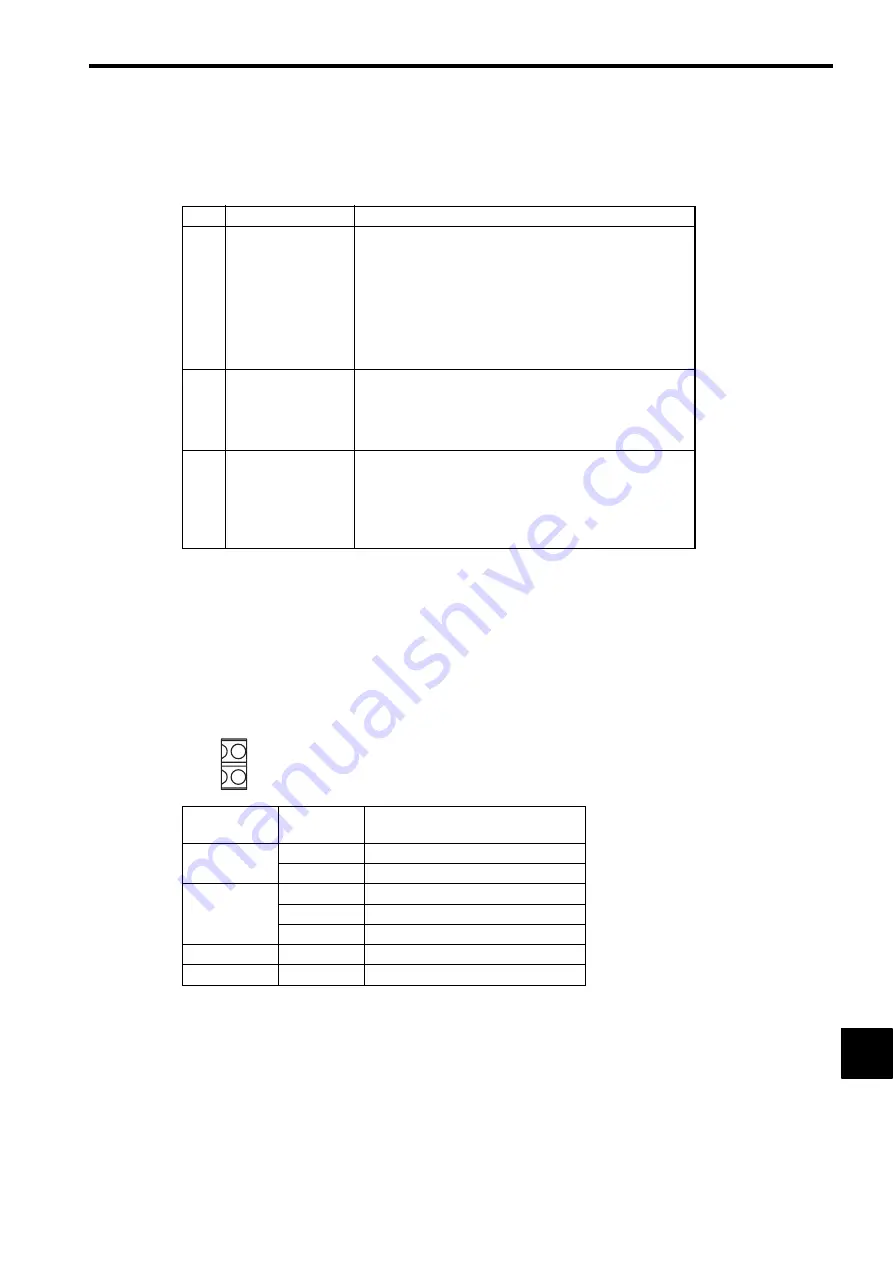

13.1.3 Indicator Errors

Error details can be checked by the status of indicators on the front of the MP2100/MP2100M Module.

In the process, we narrow down the repair location in a program by getting an overview of the error from indica-

tors, checking the contents of the system (S) registers, examining the drawing or function number that caused the

error and then getting an overview of operation error details.

(1) Indicators

The following indicators show operating status and error details for the MP2100/MP2100M.

No.

Point

Basic Details Examined

1

Visual Check

• Equipment operation (status while stopped)

• Power ON/OFF

• I/O equipment status

• Wiring status

• Status of indicators

• Status of all switches (mode switches and other switches)

• Parameters and program content check

2

Error Check

Observe whether the following alters the error in any way.

• Stopping the MP2100/MP2100M.

• Resetting the alarm.

• Turning power OFF and ON.

3

Narrowing the

Range

Consider possible failure locations based on the results of 1

and 2 above.

• Is the problem in the MP2100/MP2100M or external?

• Is the problem in sequence control or motion control?

• Is the problem software or hardware?

Indicator

Name

Indicator

Color

Significance When Lit

S1

Green

Lights for normal operation.

Red

Lights/blinks for failures.

S2

Not lit

User program stopping.

Green

Lights for normal operation.

Red

Lights/blinks for warning.

TX

Green

Data is being sent to M-I/II.

BAT

Red

Battery alarm occurred.

BAT

TX

S2

S1