2.2 A: Initialization Parameters

YASKAWA

TOEPYAIGA8002B GA800 Drive Programming

191

and motoring/regeneration on the machine side before you use the function. If there is a polarity error, shock can

increase.

Item

Description

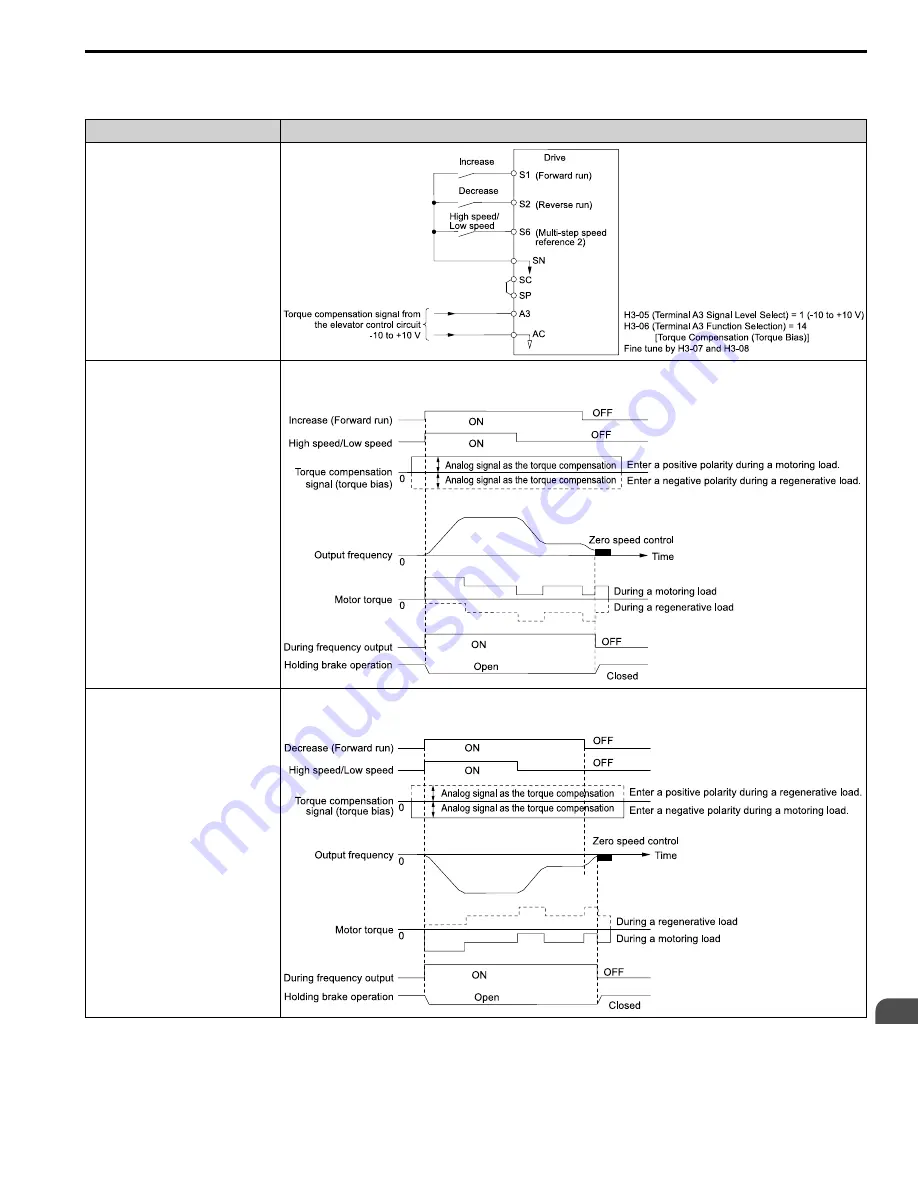

Sequence Circuit Configuration

Time chart: Increase

Enter the analog signal as the torque compensation (torque bias) signal as specified by the load quantity before drive operation until drive

operation completes. The default setting is 10 V/100% torque.

Enter a positive polarity during a motoring load, and enter a negative polarity during a regenerative load.

Time chart: Decrease

Enter the analog signal as the torque compensation (torque bias) signal as specified by the load quantity before drive operation until drive

operation completes. The default setting is 10 V/100% torque.

Enter a negative polarity during a motoring load, and enter a positive polarity during a regenerative load.

Содержание GA800 Series

Страница 2: ...This Page Intentionally Blank 2 YASKAWA TOEPYAIGA8002B GA800 Drive Programming...

Страница 14: ...i 2 Using the Product Safely 14 YASKAWA TOEPYAIGA8002B GA800 Drive Programming...

Страница 172: ...1 22 Parameters Changed by PM Motor Code Selection 172 YASKAWA TOEPYAIGA8002B GA800 Drive Programming...