Group

28

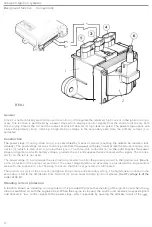

Ignition

systems

Des

ign

and

function

-

Overview

Review of electronic

ignition systems

-

II

EZ

-

l02K

was

i

ntrodu

ce

d

in

1984

in conjunction

with the

launch of

the 760 Turbo with

the

823 FT engine and lH 2.1

fuel

injection

system on the American

market.

EZ-102K

is

with a thermostat which transmits a signal to

one

of

the control unit terminals when the engine temperature becomes excessive

.

commanding it

to advance

the

timing

the throWe

i

s

closed.

The f

i

rst EZ

-

K

system

to

be used by Volvo

,

EZ

-

102K remained in production only for a

year before be

i

ng

superseded by more up-to-date variants

according as the new family of engines was

introduced.

EZ-117K

is very similar

to EZ

-

102K

in

configuration,

although designed for the

8230 F

and

8230

FT engines

with the

lH..Jetronic

2.2

fuel

injection system.

The

system

was

introduced

with the new family of engines

in

1985.

The

8230 FT

variant

features a knock-controlled fuel enrichment function

.

its

predecessor

,

EZ

-

102K

,

the turbo engine

variant

i

s

equipped

w

i

th a thermostat which activates a timing advance function to

protect the

engine from over-

heating

.

EZ

-

118K

differs most from the

other systems

the group

.

due to the fact that it depends on a vacuum

connec

tion be-

tween

the

intake

manifold and

control

un

i

t to

supply

engine

load

i

nformation

,

rather

than

on a

load

signal supplied

by an air mass meter via

the

fuel

system control

unit. The

system

also

emp

loys

an idling switch mounted on

the

thr

o

ttl

e

pulley

rather

than a

s

witch

mounted

on

the throttle housing

.

EZ

-

1

18K

was introduced in

1

985 on

the

B

200

E

.

8230 E

and

B

230 K engines.

Tw

o idling compensa

ti

on

functions may be used on

E

Z-1

18K

varian

t

s.

The

82

3

0

K

va

r

iants a

r

e equipped with a temperature

sensor,

while

the

co

ntrol

unit opera

t

es a so

l

enoid valve

which

in

te

rr

upt

s

the

fuel supp

l

y under engine braking conditions.

Most

of

the

differences are a

ttributable

to

th

e

fact

t

ha

t th

e system

used

on carbura

t

ed

engines

(now

with Pierburg

carb

urettor

s)

and on E engines

with the

C

I

system

(

K

-Je

tronicl.

EZ

-

115K

has been designed especially for the 8280 engine. Its

features

two kn

oc

k

sensors (one

for

each

bank

of cylinders), a position

detector for No

.

1

cylinde

r

,

a knock-controlled fuel enrichment

function

and an

induct

ive

speedJposition

pick-up mounted

at

the flywheel. Depending on

the

temperature sensor

t

he control

un

i

t

can

apply tim

i

ng

compensation

by retarding the ignition when the engine is

cold

t

o

achieve

faster

heating of the coolant

.

and

by advancing

when the engine tends to run too hot. The

sys

tem

appeared

in

1987

with

the

in

troduct

ion

of the

8280 engine to replace the

B

28

,

and

is,

therefore

,

used only

on

the 760/780

.

EZ-1

15K

is used in combination

w

i

th

LH-

Jetronic 2

.

2 on both the

E

and F

variants.

EZ-116K

is

a refinement

of other

EZ

-

K

systems.

However

,

it

features advanced self-diagnostics which facilitate fault

tracing and monitoring

.

The

control unit continuously

mon

i

tors the

various sensors

and functions

,

and any faults

present may be d

is

played w

i

th the

aid of a

d

i

agnostic un

i

t

mounted in

the engine

compartment.

EZ

-

116K was

in-

troduced

i

n 1988

on

the

8234F

engine used in

the

7

4

0

GlT

.

Unl

i

ke other EZ-K systems used on

4-cyl

inder

engines in the

700 series,

EZ

-

116K

equipped

with an

induc

t

ive speedJposition

pick-up mounted close to

the

fly-

wheel instead of a Hall generator

in

the distributor

.

The system is used

in combina

ti

on

with the

very

latest fuel

in-

jection system (LH·Je

troni

c

2

.

41

.

Manufa

c

tured

by

8endix

,

the

Rex

-

I

system

is equ

i

pped with the

same

type of diagnostic system as

EZ-116K

.

Used in

conjunction with the Regina fuel

injection system,

Rex-I was

introduced

in 1989 on

8230

F engines sold in

th

e US

A

.

Compensation functions

H

owever, most electronic ignition systems are equipped

w

i

th

addi

ti

ona

l

senso

rs which

enable

th

e con

tr

ol

unit

t

o

ad-

just the

timing to compensate for unusual running conditions. Thus.

sensors (

F-H

)

may

be

regarded

as p

r

oviding

th

e

ignition

system

with

compensa

tion

functions. In

t

he even

t

of engine knock

phenomenon whereby

th

e

fuel

/

air

mixture is ignited by a source other than the

spa

rk

plug), the

kn

ock sensor (FI

moun

t

ed on

the

engine wi

l

l transmit a

signal to the

control unit commanding it

t

o

retard the

igni

t

ion.

Complete closure of

the

throttle

is indica

ted

by a

throt

-

tle

switchlidling switch

(

G). When the

engine is idling.

t

he control

unit regulates

the t

iming

in accordance wi

t

h

an

'i

dling program

'

to

ensure optimum

co

mfort

,

while

the t

iming

under

engine

braking

condi

ti

ons

is controlled to mini-

mize exhaust

emissions.

The

signal supplied

to the

control unit

by the temperature sensorhhermostat

enables

the

un

i

t to

apply

the appropriate t

i

ming

co

mpensat

io

n when the

engine

temperature is unusually h

i

gh or

low.

7