Group

28

Ignition systems

Design

and function

- System descriptions

4

9

10

1

7

EZ

-

102K

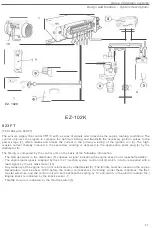

EZ-102K

823FT

(760,1984 with 823FT)

The

sensors supply

the

control

(

1)

with

a series of signals which descr

i

be the engine

running

conditions

.

The

control unit uses the signals to compute the optimum

timing

and

transmits the

necessary ignition pulses to

the

power stage

(

2), which

makes

and breaks

the

current in the primary winding of the

i

gnition coil (3). The

high

-

tension

current

thereby

induced in the secondary winding

is

de

l

ivered to the appropriate spark

plug

(4) by the

distributor

(5).

The timing

is computed by the control unit on the basis of the

following

i

nformation

:

-

The Hall

generator in the distributor (5) supplies a signal indicating

the

engine speed and crankshaft

position.

-

The engine load signal is supplied by the LH

-

2.1 in

j

ection

system control

unit

(9) which, in

turn

,

is supplied with

a

load

signal by the air

mass

meter (10)

,

-

Any

tendency of the engine to run hot is indicated by a

thermostat

(8).

(

The throttle must be closed and the engine

temperature

must

be

above

103

°

C before

the

control unit advances the

timing

.

Under

these

conditions,

the ther

-

mostat

will close, and

the

control unit will both advance

the

setting by

13

°

and switch in

the

electric radiator fan.

)

-

Engine knock

is indicated by the

knock

sensor

(

7

),

-

Throttle

closure is indicated by the throttle switch (6)

.

47