Group

28

Ignition systems

D

esign

and function

- Compensation functions

r---

o

-16

..1

0'_2

0

_3

·

0'_4

0

0'

_6

0

_7

0

0'

_6

0

O'

_g

O

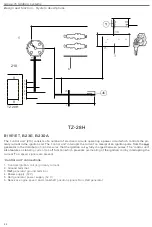

Knock control

r---

r---

The kno

c

k

sensor moniiors the

combus

t

ion

process

contin

uo

usly.

If

knock

occurs,

the device delivers a special sig.

nal

to

the control unit, which takes corrective

ac

t

ion

by

retard

ing

the ignition

the

cylin

der

affected.

Knock control

characteristic

The

principle of knock

control

is more

o

r

less the same

in

the

case

of all systems equipped

with knock

sensors. (AI·

though the kn

ock cont

rol

characteristic shown is

that

for the EZ·115K system, the description is generally applica-

ble.) The

vertical

coordina

te

shows

the

ignition setting in degrees in relation

to

the basic timing

(i

ndicated

here

by

the

ang

l

e

while

the

horizontal coordinate

is

the time scale

(which

normally varies wi

th

eng

i

ne speed).

Stepped control

The

control

unit

continuously compu

t

es

the

optimum

t

iming

on the basis of the

running

conditions. On detecting

knock,

the unit retards the ignition by a

ste

p

of a

few degrees

depending on the system)

the cylinder affected.

I

f

the phenomenon

persists,

the

setting is

retarded

by a further step, and

so

on until

the

condi

tion has

been correct-

ed.

The

maximum retardation

in

relation to the basic

t

iming

i

s approx.

in

th

e

case of

EZ

-

K

systems.

Ae-advance following correction of knock

After

knock

h

as

been eliminated,

th

e

control unit maintains the retarded setting for a

speci

fied

number of engine

rev

-

o

lut

ions,

depending

on

the

speed (app

lies

to EZ-K

before re-advancing the

igni

t

ion

in small steps (0.1-1

°

),

eithe

r

until

the

original

characteristic has been

restored or

until the

engine again

starts to

knock

.

• T

he

maximum

retardation

must

not deviate excessively

from

the

setting if an

excessive rise

in

exhaust gas

is

to

be

avoided

.

Informa

t

ion

on

engine speed

and

for

load

is also essential to enable

the

cont

r

ol unit

to impose

the

maximum

retarda

-

tion

,

if

necessary

.

32