Group

28

Ignition systems

Des

ign

and

fun

c

t

ion -

Speed

and

crankshaft position

i

nformat

ion

c

I

,

c

·

TOC

B

TOC

-

A

Flywh

eel/

c

a

rr

i

er plate pr

ofi

l

es

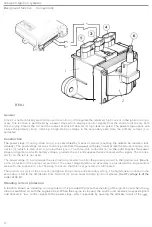

The

above

figures

show

the three

different

'

Ioothed

'

or drilled crankshaft/carrier plate

profiles which are used

.

(The

profiles

afe

shown

in section

.)

Unlike

the

starter motor ring gear, which

is

moun

t

ed on

the flywheel. the profile

used

for

signal generation is usually an integral part of the component.

Volvo

igni

tion

systems are supplied mainly by

two

manufacturers

-

Bosch of Germany and

Bendix

,

France

.

Among

other factors.

this

means

that

several different profiles must

be

used. while

the

method

whereby the

control unit

tects and processes

the

induc

tive

pick-up signals may also differ

.

The electronic circuit

(

which

may be likened

to

a

frequency

divider or

'mul

tiplier'

)

in

wh

ich

the

signal is

f

i

rst received

and processed, also varies in design

.

The frequency of

the

incoming

voltage pulses is

divided

by a certain

factor to

i

mprove

signal resolution.

Th

is,

in

t

urn, means

that the

cont

r

ol unil

can

regulate

t

he

t

iming

in

more precise

steps,

for

example,

when re-advancing

t

he

t

iming

afte

r

knock in a cylinder

has been

elimina

t

ed.

A

.

I

gnition systems

supplied by

B

endix employ

a

type

4412 toothed

profile. The

figure 44 means

t

ha

t the

flywheel

is

provided with

44 dr

illed

holes

,

and

t

he

figure

2

that

i

t

has two

'

long

'

teeth

,

each equal

leng

t

h

to

tw

o sho

rter

teeth.

In

o

th

er

w

ords,

the

profile

provided

with

40

(

44

-

2x2

)

sho

rt t

eeth

and

tw

o

l

ong

t

ee

th

.

T

he

angular pitch be-

tw

een

tw

o a

dja

cen

t

short

t

ee

th

(X

O

)

is 8.

18

°

(360

°

/

44

).

The two

long

teeth

com

pris

e

the

c

rank

s

haft

position

referen

ce

points

are

located

180

°

apart

(angle

a

).

The

con

tr

ol

unit identifies

TDC a

s

th

e

90

°

after

the

passage

o

f

a

l

ong tooth

.

Th

e

type

44/2

profile

is

used

on

A

e

nix

-F

and

R

e

x

-I sys

t

ems.

In

each case,

the

control

unit

applies a

factor

o

f 8

.

18 t

o

improve the

signal resolution. This

means

th

a

t

it

can

adjust

th

e

timing

in

steps

of

8

.

I

gni

ti

on systems supplied

by Bos

c

h for

Vo

l

vo

4-cylinder

engines

f

ea

ture

a

type 60/1

t

oothed p

r

o

f

i

le

.

This means

t

hat

th

e

profile

is

provided with

60

holes and with

one

'

long

'

t

ooth

of

tw

ice

the

length of a

's

hort'

t

oo

th

.

In

other words

,

the

pr

ofile is provided

wit

h 58 (60-

1x

2) short

teeth

and one long

tooth whi

c

h represents

t

he

crank-

shaft

posit

io

n reference

point

.

The

angular

p

i

t

ch

between two

adjacen

t

sho

rt t

ee

t

h

is

6

.

0"

Th

e con-

trol un

i

t

i

dentif

i

es TDC

as

the

point

after

the

passage of

the

long

t

oo

t

h.

The type

6011

t

oo

t

hed profile

is

used

on

the

EZ

-1

16K

system

.

This means

that the

con

trol

unit applies a

factor

of 16

to

improve

the

resolution

of

the pick-up

signal.

In effect

,

the

control unit can adjust

the t

iming

in steps of

C

.

The EZ-1 15K

igni

tion

system for B 280 engines

is

designed for a flywheel

with

a type 6013

toothed profile.

The

file

is provided

with

60

holes and 3

'long'

teeth

,

each of which

twice

the

length of a

'sho

rt

'

tooth

.

In

other

words

,

the profile

is

prov

ided

w

i

th

(60-3

x2

)

short

leeth

and 3

long

teeth as the

crankshaft position

reference

points

.

The

angular

p

i

t

ch

between

two

adjacent short

teeth

(Z

O

)

is

(360

°/

60).

The

t

hree

long

t

eeth are

located

12

0" apart

la

ngle

cl.

The

control unit

iden

tif

ies

TOC

as

the point

after

the

passage of a reference

tooth

.

Th

e

con

t

rol

un

i

t applies

a

f

actor of

16

t

o

im

prove

the

resolut

io

n

of

the

pick-up signa

l

.

I

n

o

th

er

words

,

the unit

adjus

t th

e

ti

ming in s

t

eps of 0.375

°

.

24