Group

28

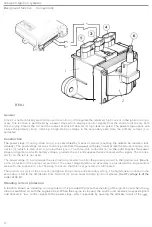

Ignition systems

Design and

function

- General

B

A

c

o

II

I

1

1

1

Ignition systems - basic parameters

Th

e ignition

system control unit

must

be supplied

with

certain basic

information

in order

to

compute

the frequency

o

r r

a

t

e a

t

w

h

ich

HT

ignition

pulses

must be delivered

to

the spark plugs,

when

(in

relation to the position

of

t

he par-

t

icula

r

piston before TOG)

each pulse must be generated and

to

which

plug

the

pulse

is

to be

delivered.

T

he

signals

requi

r

ed for this purpose

are

derived from the

engine speed (A), engine load (B) and crankshaft

position

(G).

Speed information

A

.

T

he

engine speed provides information on the number of ignition pulses which must be generated per

unit

of

time.

T

he number

of

high-tension

(HT)

pulses

delivered to the plugs must be increased as the engine speed

rises.

The speed

signal is

the

most vital piece of

information

supplied

to

the control unit. For example,

the

engine cannot

be

started in

this

signal

is

unavailable.

T

he control unit a

lso

uses

the

engine

speed

to

determine

the

point at which

the

ignition

pulse

must be delivered in

r

elation

to the position

of

the piston

before

TOG.

Ignition must

take

place earlier at higher speeds since the

upward

and

d

ownward

movement

of

the

pistons is faster under these conditions. As a result, the

time

available for combus-

tion of the fue

l

/

air

mixture is less and the timing must be advanced

to

ensure

that

the mixture is burned as comple

t

e-

l

y

as possible.

Load information

B

.

Except

in

turbocharged

engines, the engine

load

varies

with the

vacuum in

the

intake manifold.

A

t

low

l

oads, the

th

r

ott

l

e

is

only partially

open and

the

flow of induction air is low, resulting in a high vacuum.

At higher loads, the

thro

ttl

e opens wider

and more air is supplied

to the

engine. Under these conditions,

the

vacuum in

the

manifold ap-

p

r

oaches closer

to atmospheric pressure

as

the

load is increased. It follows from

this

that a greater quantity of fuel/

air mixture is

available

for

combustion as engine load increases and

that the

higher volume of gas

produced

rein-

f

o

r

ces

t

he pressure

due

to

compression. Since the rate of combustion is accelerated by higher gas compression,

the

t

iming is retarded as engine load is

increased

.

At low engine loads, on

the

other hand.

the timing

may be advanced

t

o compensate

for the

low

er rate

of

combus

t

ion

and

to improve

fuel utilization.

Crankshaft po

s

ition information

C

.

The

crankshaft position

(i.e.

angle

)

provides information on the position of each piston in

rela

t

ion

to

TOC.

This

formation

is essential to

the

system control functions. which compute

the timing

continuously on this basis.

11