Group

28

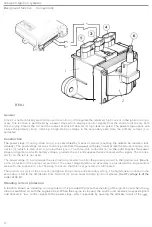

Ignition systems

Design

and function - Speed and crankshaft position

information

Speed and crankshaft

position information

A

8

N

Hall generator

Function

and

location

The Hall

generator (1) supplies

the

control uni

t

with information

on engine speed

and

crankshaft

position. The de-

vice

is

mounted inside

the

distributor

cap.

Construction

:

The generator

is

based on

th

e

principle

of

the

Halt

effect, whereby the flow of current in a semiconductor is

deflected

if the

componen

t

is exposed to a magnetic field. This causes a potential difference (i

.

e. an excess of e

l

ec

tr

o

n

s on one

side of the

semiconduc

tor

and a deficiency on

the

producing a voltage

known

as

the Hall

vol

t

age.

Following

amplification, this voltage is employed by the

cont

r

ol

unit as a

signal

to

con

trol the timing

.

The Hall

generator (1) is

a U-shaped

element

w

i

th an opening for the trigger

ro

tor

(2).

The number

of

rotor

vanes is

the

same as

the

number of cylinders in

the

engine.

The generator

consists of a

Hall

-Ie

element (3)

co

mprising a Hall

effect detector

and a transistor amplifier

.

A magnet

(4)

with

a

three

-

pole

connector

(5) is

located

on

the opposite

side of

the

rotor

t

o

the

Hall

·

IC element

.

The

connec

tor

term

inals

are connected respectively

to

a

12

V supply

(+),

a 5

V reference signal

from the

control

unit

(01

and ground

(-)-

Signal

A

.

In th

is

position,

the

magnetic field

is

blocked by

the tr

igger

rotor

vane and

the Hall effect

is

absent. No

voltage is

induced

in

the Halt-IC element

and

the

ground connection

rema

ins

open.

As a

result, a

5

V signal

present atter-

minal

(01.

B

.

In this

position,

the

rotor exposes

the Hal

l·

IC e

le

ment to the

influence of

the magnetic f

ie

ld and the

resultant

Hall

voltage

fed to the transistor

amplifier.

The 5

V signal

at terminal

(0)

is then

connected

to ground across

the

terminal

and

the

voltage at (0)

falls to

0 V.

Thus, the

signal

from the Hall

generator

varies between 0 and

5 V

in the form of a square-wave

signal,

the control

unit deriving

its

engine speed

information

from measurement

of

the duration of the alternating half waves.

crankshaft

position signal

is

obtained by adjusting the basic

se

tt

ing of

the distributor

to

coincide

with the

posi

t

ive

flank

of

th

e

Hall generator signal

(i.e.

the half-wave generated when

the

rotor blocks

the magnetic

field) a few

cranksha

ft

degrees before TDC.

20