Group

28

I

g

n

i

tion

s

ystems

Design

and

function

Sys

t

em

descriptions

3

\

4

RENIX

-

F

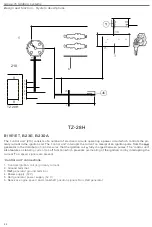

RENIX-F

B200K

(The above

illus

tr

a

t

io

n and

t

he

following text

are

based

on

the B

200

K

engine used

in

the 740)

The

sys

tem

consis

t

s o

f

an electronic

co

ntrol

u

nit

(

1

)

whi

ch is supplied

with

engine speed an

d

c

r

anksha

ft

position sig

-

nals

by an

i

ndu

c

tiv

e

speed/position

p

i

c

k

-

up

Th

e

pick

-up

detects

th

e

passage of a number

of

'

te

eth' o

n

the

fly

-

wheel

(

3)

.

The

co

ntro

l

unit

is a

l

so

sup

pli

e

d with

i

nf

or

mation

o

n

eng

in

e

load

through

a vacuum

l

ine (

4

) co

nne

c

ted to

the intak

e

manifold,

the

pressure

in

which

ac

tu

a

te

s

a vacuum advance

un

it

(5) in

tegr

al

with th

e

unit

.

The

s

p

eed and

l

oad signals are

pro

cessed

by

th

e co

ntr

ol

unit

electronics and compa

r

ed

with the timing

se

tt

ings

stored

in

the memory.

Hav

ing

used the

information

t

o compute

the

op

timum

timing

,

the unit

t

ransmi

t

s

co

ntrol

sig-

na

l

s

t

o an

integral power

stage

wh

ich

makes and

breaks

t

he current in

the

primary

w

i

nding of

the

ignition

at

the

correct ins

tant

,

gene

ratin

g a high

-

tension

curren

t

the

secondary

.

The

HT

pulse

fed

to

t

he d

i

s

t

ribu

t

or

(7

)

for

del

ivery

t

o

th

e appropria

t

e spark plug

(81

.

Apart

from the rotor

,

the

distr

i

butor

con

tain

s

no mechanical

or

electronic

co

mponents

,

its

sole

funct

io

n being

to

dis-

tribute the

high

-

tens

ion cur

rent

to

the

co

rre

c

t plug

.

•

At

idl

i

ng

speeds of

less than

1000

r

I

m

in,

the

cont

r

ol u

n

i

t

t

he

t

iming

by

t

o

prevent

a drop

i

n

whe

n

the AC

system

is

sw

itched on or

when a drive

position

i

s selected on

an automat

ic

mod

e

l.

45