SINUS PENTA

PROGRAMMING GUIDE

44

/

486

attained. Decrease

P128

and

P129

by approx. 30%, then decrease the high values set for integral

time in

P125

and

P126

(keep both values equal) until an acceptable setpoint response is obtained.

Check to see if the motor runs smoothly at constant speed.

10) Possible

failures:

If no failure occurred, go to step 11. Otherwise, check the drive connections paying particular

attention to supply voltages, DC link and input reference. Also check if alarm messages are

displayed. In the MEASURES MENU, check the reference speed (

M000

), the reference speed

processed by the ramps (

M002

), the supply voltage of the control section (

M030

), the DC-link

voltage (

M029

), the condition of the control terminals (

M033

). Check to see if these readouts

match with the measured values.

11) Additional

parameter

modifications:

If the motor control is underperfoming, make sure that the following measurements are consistent

with the expected motor operation:

- estimated speed

M004

in respect to speed ramp

M002

,

- output frequency

M006

,

- generated torque

M012

and torque demand

M011

,

- output current

M026

,

- output voltage

M027

.

Proceed as follows:

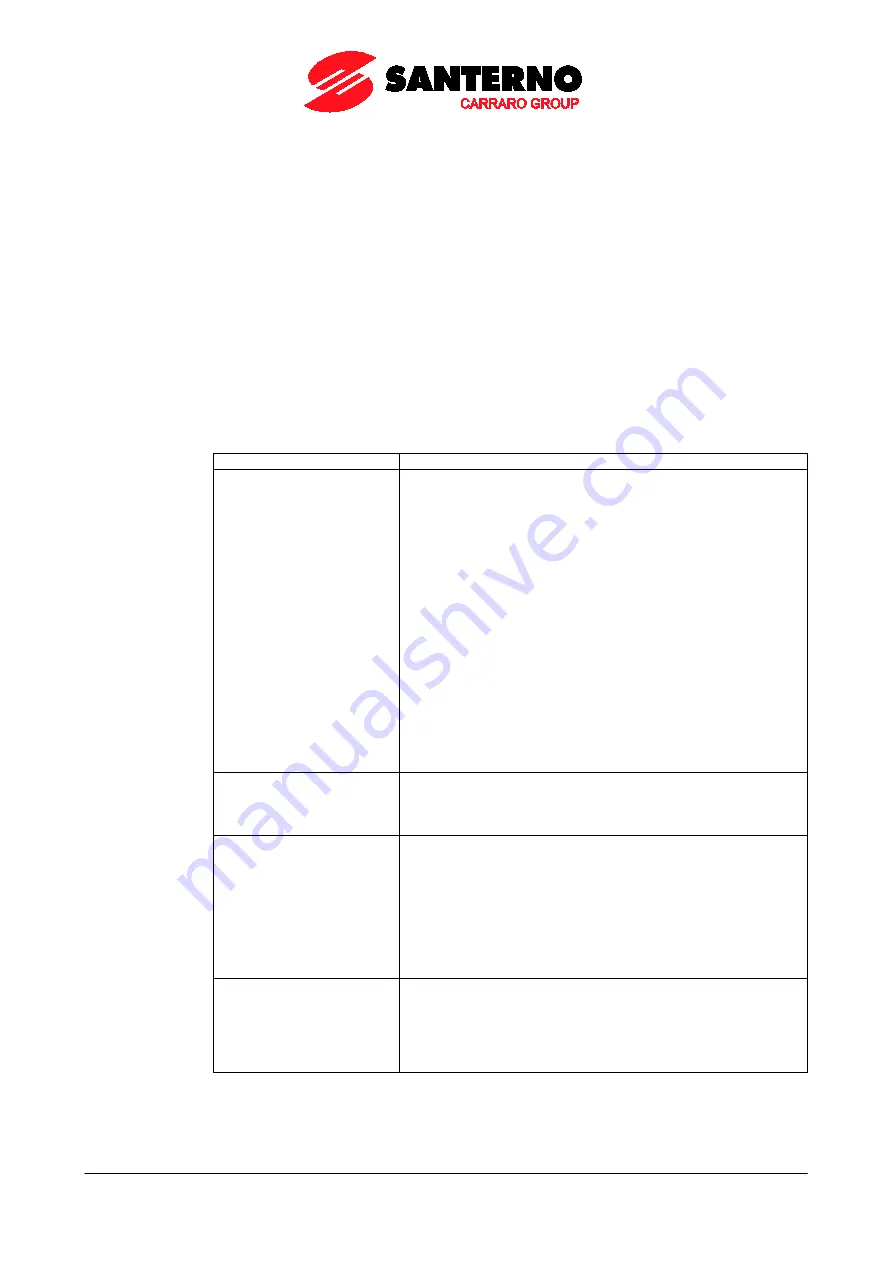

Issue

What to do

Generation of weak torque

or inaccurate torque

delivery

Increase the flux boost at low frequency

P175h1

and adjust the

frequency range for the boost to occur via parameters

P175i1

and

P175j1

. The magnetization current at low frequency with

active current boost equals the no-load current value in

C021

increased by the value in

P175h1

(for example, if

C021

=27%

and

P175h1

=30%,

the magnetization current is

27%x1.3=35.1%). Up to the frequency value in

P175i1

, the

magnetization current is

C021

x (1+

P175h1

); at a frequency

higher than

P175j1

, the magnetization current is

C021

; at

intermediate frequency values, the magnetization current follows

a linear pattern. Too high magnetization current values may lead

to saturation of the motor flux, lower efficiency due to greater no-

load current, inaccurate torque adjustment or controller

instability. It is suggested that

P175j1

be applied at its maximum

value up to 50% of the rated frequency. Also, set

P175i1

in such

a way so as to obtain a rather smooth pattern (for example,

P175i1

set to half the value in

P175j1

). In case

P175i1

and

P175j1

are not correctly adjusted, torque adjustment may be

uneven or current variations may occur.

Generation of weak torque

at high speed

If the motor is not capable of delivering high torque at high speed

(close to rated torque or field weakening torque) or requires

excessive current in respect to the expected current, it is

possible to adjust rotor time constant

C025

.

Generation of weak torque

at low speed or in

regenerative mode

Change current distortion compensation parameters in VTC

control

P175a

,

P175b

,

P175c

. Change current distortion

compensation

P175b

first, then change positive and negative

current split

P175c.

For high values in

P175b

, also increase the linear pattern

threshold in

P175a

. If parameter

P175b

is set too high or

P175a

is set too low, rotor oscillations may occur, or it may happen that

the rotor is not kept standstill even in no-load conditions. If this is

the case, set lower values for the parameters above.

Low output voltage or weak

torque in field weakening

mode

Disable static field weakening by setting

C030

= Disable and

enable automatic field weakening by setting

C030a

>0.

In that way, the field weakening amplitude is automatically

adjusted to ensure adjusting the required speed at the maximum

allowable voltage fitting the rated motor voltage and the available

DC voltage.

When parameter

P003

= Standby Only (condition required for changing

Cxxx

parameters), you

can change

Cxxx

parameters only when the drive is DISABLED or STOPPED, whereas if

P003

=

S Fluxing, you can change

Cxxx

parameters when the motor is stopped but the drive is

enabled.

Before changing any parameters, remember that the correct code for parameter

P000

must be

Содержание PENTA MARINE

Страница 173: ...PROGRAMMING GUIDE SINUS PENTA 173 486 Figure 27 Response to the step based on the value of Kp when Ti is kept constant...

Страница 196: ...SINUS PENTA PROGRAMMING GUIDE 196 486 Figure 34 ANALOG Mode Figure 35 DOUBLE DIGITAL Mode...

Страница 197: ...PROGRAMMING GUIDE SINUS PENTA 197 486 Figure 36 General structure of the parameterization of a digital output...