b.

If the fold is a

down

fold, the next page printed is a front-facing page.

2.

If the fold direction is the way you want

, do the following to start or continue

a print job:

a.

If necessary, select

Next is Back

. The message on the panel changes to

Next

is Back

, and the

Next is Back

button is grayed out. Selecting the

Next is

Front

button changes the message and the buttons back to what they were

originally.

b.

Select

Close

.

3.

If the fold direction is not the way you want

, do the following to start or

continue a print job:

a.

Advance the forms by one page by using one of the following methods:

v

On the printer operator panel or the Align Forms panel, select

NPRO

.

v

From the touch panel, select

Forms

→

Advance Paper (NPRO)

and select

Advance One Page

.

b.

If necessary, select

Next is Back

to set the panel message text to agree with

the fold direction. The message on the panel changes to

Next is Back

. The

Next is Back

button is grayed out.

c.

Select

Close

.

Checking forms alignment

About this task

Do this procedure to check forms alignment. Do this procedure when you see a

CHECK FORMS ALIGNMENT

message or whenever you load, splice, or adjust forms.

Procedure:

Procedure

1.

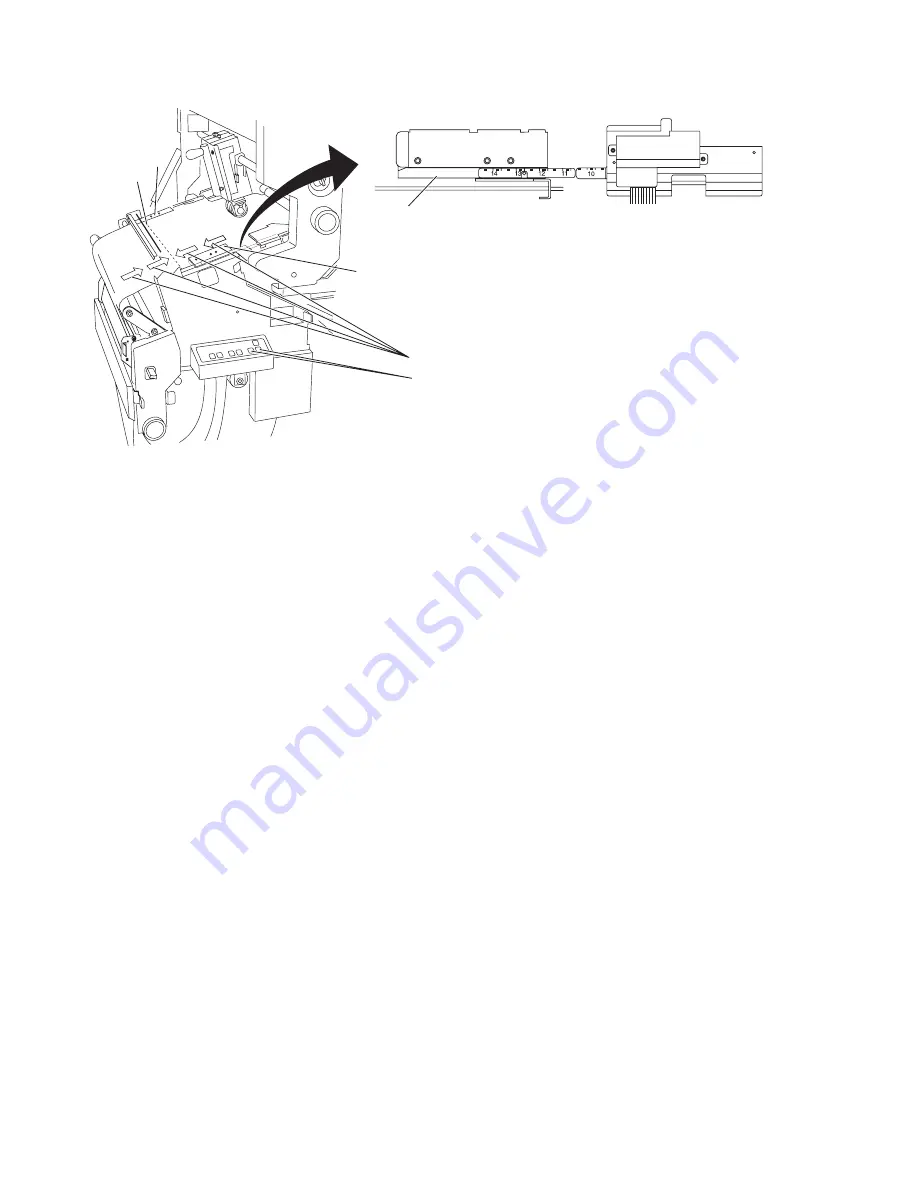

At the lower transfer station tractors, ensure that the forms perforation

(1)

is

aligned with the correct forms length on the tractor scale

(4)

.

c0tu019

1

5

5

4

2

3

Figure 81. Forms fold at the alignment guide

188

Operating the InfoPrint 4100

Содержание InfoPrint 4100 TD3

Страница 1: ...Operating the InfoPrint 4100 InfoPrint 4100 Models TS2 TD3 4 TS3 and TD5 6 S550 1298 02...

Страница 2: ......

Страница 3: ...Operating the InfoPrint 4100 InfoPrint 4100 Models TS2 TD3 4 TS3 and TD5 6 S550 1298 02...

Страница 8: ...vi Operating the InfoPrint 4100...

Страница 12: ...x Operating the InfoPrint 4100...

Страница 14: ...xii Operating the InfoPrint 4100...

Страница 60: ...46 Operating the InfoPrint 4100...

Страница 90: ...6 Open the lower tractor covers on the transfer station g5amc377 1 1 2 3 4 76 Operating the InfoPrint 4100...

Страница 97: ...2 Swing the roller 3 into the open position by pressing down on 1 and 2 Chapter 5 Working with forms 83...

Страница 107: ...4 Open the lower tractor covers on the transfer station ic3mc335 2 4 3 1 Chapter 5 Working with forms 93...

Страница 127: ...2 Swing the roller 3 into the open position by pressing down on 1 and 2 Chapter 5 Working with forms 113...

Страница 140: ...2 Swing the roller 3 into the open position by pressing down on 1 and 2 126 Operating the InfoPrint 4100...

Страница 268: ...254 Operating the InfoPrint 4100...

Страница 360: ...346 Operating the InfoPrint 4100...

Страница 407: ...Administrator panel Chapter 8 Help topics for the InfoPrint 4100 operator console 393...

Страница 408: ...394 Operating the InfoPrint 4100...

Страница 461: ......

Страница 462: ...Program Number 5765 G79 5765 G74 Printed in USA S550 1298 02...