Lake Shore Model 321 Autotuning Temperature Controller User’s Manual

D-16

Application Notes

The measured offset voltages shown in Figs. 4 and 6 can be understood

by using the well-known result from

p-n

junction theory:

I = I

s

[exp(eV / nkT) - 1]

(1)

where

I

= the forward current through the junction,

I

s

= the reverse

saturation current,

e

= the electron charge,

V

= the voltage across the

junction,

k

= Boltzmann's constant, and

T

= the absolute temperature.

n

is a parameter depending on the location of the generation and

recombination of the electrons and holes and typically has a value

between 1 and 2. This expression for the IV characteristics of a

p-n

junction is valid from approximately 40 K to above 300 K for the silicon

diodes discussed here. Below 40 K, a new conduction mechanism

becomes dominant, suggesting the influence of impurity conduction,

carrier freezeout, increased ohmic behavior of the bulk material, and

p-i-

n

diode type behavior.

1-6

The only adjustable parameter in Eq. 1 which is necessary for the

present analysis is the parameter

n

. This parameter can be determined

quite easily from the IV characteristics of the silicon diode temperature

sensor. The parameter

I

s

is eliminated by normalizing the IV curve to an

arbitrarily chosen point on the curve. The value of n = 1.8 was found to

give a relatively good fit to the IV data for both 305 and 77 K and has

been assumed in the present discussion.7 Equation (1) can now be

solved for V(I):

V(I) = (nkT / e)ln(I / I

s

+ 1)

(2)

Substituting a dc current with an ac modulation, I

dc

+ I

ac

cos

ω

t

, the

average voltage read by the voltmeter in the dc voltage mode can be

calculated from:

V

T

V I

I

t dt

dc

ac

T

=

+

z

1

0

(

cos

)

ω

(3)

where T = the period of integration of the voltmeter or approximately

2

π

/

ω

. Implied in this derivation is the assumption that

ω

is sufficiently

small so that effects from diode capacitance (on the order of picofarads)

can be ignored.

On carrying out the integration of Eq. (3) and subtracting V(I

dc

), the dc

offset voltage is:

∆

V V V I

nkT

e

eV

nkT

dc

rms

= −

=

+

−

F

HG

I

KJ

F

H

GG

I

K

JJ

L

N

MM

O

Q

PP

(

)

ln

1

2

1

1 2

2

(4)

where I

ac

≤

I

dc

+ I

s

. If a small signal (linear) model is used, the rms

voltage across the diode can be easily related to I

ac

:

V

I

dV

dI

nkT

e

I

I

I

rms

ac

ac

dc

s

I Idc

=

F

HG

I

KJ

=

F

HG

I

KJ

+

F

HG

I

KJ

=

2

1

2

(5)

Evaluation of Eq. (5) and substitution back into (4) yields:

∆

V

nkT

e

eV

nkT

rms

=

+

−

F

HG

I

KJ

F

H

GG

I

K

JJ

L

N

MM

O

Q

PP

ln

1

2

1

1 2

2

(6)

where 2(eV

rms

/ nkT)

2

≤

1 for a physical solution. Equation (6) predicts an

offset voltage which is independent of both frequency and dc operating

current and is shown plotted in Fig. 4 by the solid line. The agreement

with the experimental measurements is quite good, verifying the overall

picture as to the effect of induced currents on diode temperature

sensors. The results recorded at 305 K are described equally well by

Eq. (6).

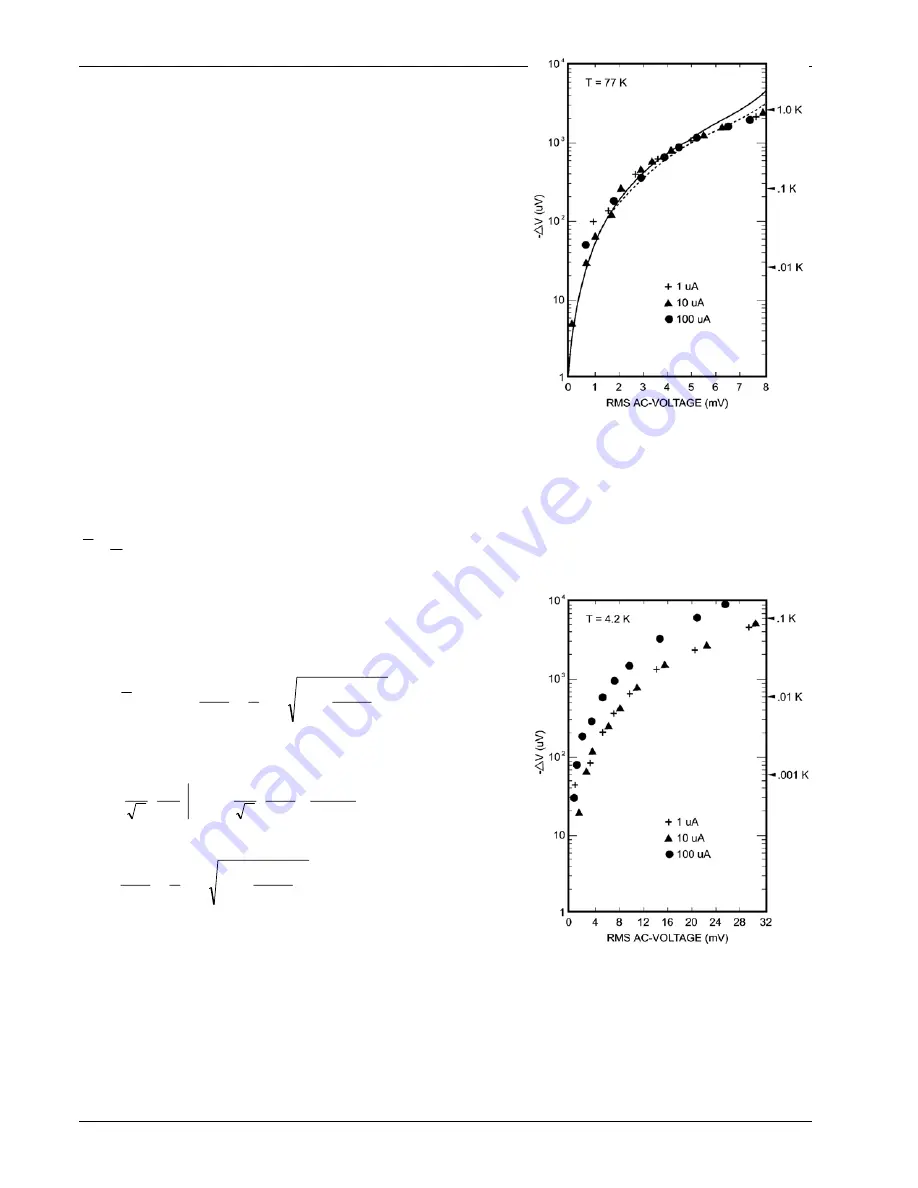

FIGURE 4.

DC offset voltage as a function of rms ac

voltage across a silicon diode temperature sensor

operating at 77 K. The symbols represent data

recorded at three different dc operating currents with

a 60 Hz signal superimposed. The solid curve gives

small signal model results while the dashed curve

represents the extended calculations. Equivalent

temperature errors are indicated along the right

edge.

FIGURE 5.

DC offset voltage as a function of rms ac

voltage across a silicon diode temperature sensor

operating at 4.2 K. The symbols represent data

recorded at three different dc operating currents with

a 60 Hz signal superimposed. Equivalent

temperature errors are indicated along the right

edge.