Lake Shore Model 321 Autotuning Temperature Controller User’s Manual

2-4

Installation

2.7 SENSOR

INSTALLATION

Abbreviated sensor installation recommendations for the Model 321 are included in this paragraph.

Please refer to the Lake Shore Product Catalog or Sensor Guide for installation details and sensor

specifications. Call Lake Shore for copies of application notes or with questions or comments

concerning sensor installation. The following are general recommendations on sensor installation:

1. Do not ground the sensor.

2. Shield the leads and connect the shield wire to SHIELD on the screw terminal connector only.

Do not connect shield at the other end of the cable.

3. Keep leads as short as possible.

4. Use twisted-pair wire. Use of Lake Shore Duo-Twist™ wire (or equivalent) for two-wire, or Quad-

Twist™ wire (or equivalent) for four-wire applications, is strongly recommended.

5. Lead wires should be thermally anchored.

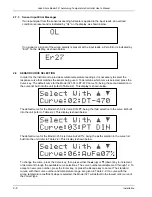

Sensor installation is provided in two parts. Diode (Model 321-01) and Platinum (Model 321-02) sensor

connections are detailed in Paragraph 2.7.1. Thermocouple (Model 321-04) sensor connections are

detailed in Paragraph 2.7.2. Finally, sensor input error messages are described in Paragraph 2.7.3.

2.7.1 Diode (Model 321-01) and Platinum (Model 321-02) Connections

The Model 321 has a rear panel 6-pin input connector for silicon diode (Model 321-01) or platinum

resistance (Model 321-02) sensors. The lead connections are defined in Table 2-1.

Table 2-1. Diode or Platinum Input Connections

Terminal Description

1

2

3

4

5

6

– Current

– Voltage

+ Current 500 µA (platinum)

+ Voltage

+ Current 10 µA (diodes)

Shield

Paragraph 2.7.1.1 discusses two-lead versus four-lead measurements. Paragraph 2.7.1.2 discusses

connecting leads. Sensor mounting is covered in Paragraph 2.7.1.3. Finally, Paragraph 2.7.1.4

describes the effect of measurement errors due to AC noise.

2.7.1.1

Two-Lead Versus Four-Lead Measurements

The use of a four-lead connection is highly recommended for two lead resistive elements and

diodes to avoid introducing current/resistive (IR) drops in the voltage sensing pair which translates

into a temperature measurement error. In the two lead measurement scheme, the leads used to

measure the sensor voltage are also the current carrying leads. The resultant voltage measured at

the instrument is the sum of the temperature sensor voltage and the IR voltage drop within the two

current leads. Since in a cryogenic environment, the flow of heat down the leads can be of critical

concern, normally wire of small diameter and significant resistance per foot is preferred to minimize

this heat flow. Consequently, a voltage drop within the leads can be present.

1. Two-Lead

Measurements

Sometimes system constraints dictate the use of two-lead measurements. Connect the positive

terminals (V+ and I+) together and the negative terminals (V– and I–) together at the

instrument, then run two leads to the sensor.

I+

V+

I

V

Two-Lead

Measurements