Lake Shore Model 321 Autotuning Temperature Controller User’s Manual

Installation

2-7

2.7.2 Thermocouple (Model 321-04) Connections

The thermocouple input has a thermal block for connecting thermocouple wires. The positive and

negative terminals correspond to V+ and V– and should match the polarity of the thermocouple used.

Be sure to tighten the screw terminals carefully. Loose connections will result in unstable readings

and control. For additional information on thermocouple operation, refer to Paragraph 3.5.

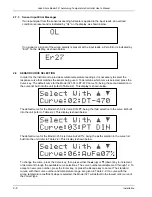

2.7.2.1 Thermocouple

Compensation

The thermocouple input has a thermal block for connecting thermocouple wires and for temperature

compensation. The thermocouple response curve tables within the instrument are normalized to the

ice point of water. Consequently, accurate readings can be obtained by one of two methods. An ice

bath with a reference junction can be used with the internal room temperature compensation turned

OFF. The more convenient method is to eliminate the reference junction with its associated ice bath

and use the internal electronic room temperature compensation by turning the internal

compensation ON.

2.7.2.2

Thermocouple Wire Types at Cryogenic Temperatures

Below are recommended thermocouple wire types for cryogenic temperatures. The ANSI color

code for thermocouples is red for the negative lead, while the type of thermocouple determines the

positive lead color: purple (Type E), black (Type J), yellow (Type K), and blue (Type T). For details

on thermocouples or other sensors, see the Lake Shore Temperature Sensor Guide.

Chromel™ vs. Gold with 0.03% or 0.07% Atomic Iron

(0.03% not currently sold by Lake Shore)

Consists of Gold (Au) doped with 0.03*

or 0.07 atomic percent Iron (Fe) as the negative

thermoelement and a Ni-Cr alloy (Chromel™) as the positive thermoelement. This thermocouple

has relatively high temperature sensitivity below 25 K, and usable sensitivity below 10 K. It is

widely used in cryogenic applications due to its relatively high thermoelectric sensitivity (>15 µV/K

above 10K). Recommended useful temperature range for the 0.03% Fe is 4 K to 325 K, and for

the 0.07% Fe is 1.4 K.

Type E (Chromel™-Constantan)

Type E is a thermocouple pair consisting of a Ni-Cr alloy (Chromel™) as the positive

thermoelement and a Cu-Ni alloy (Constantan) as the negative thermoelement. It has the highest

sensitivity of the three standard thermocouples (E, K and T) typically used for low temperature

applications: 8.5 µV/K at 20K. This thermocouple is best for temperatures down to 40 K. It is

recommended for oxidizing or inert environments. Do not use it in sulfurous or reducing

atmospheres, or environments that promote corrosion. Recommended useful temperature range

is 3 K to 475 K.

Type K (Chromel™-Alumel™)

Type K is a thermocouple pair consisting of a Ni-Cr alloy (Chromel™) as the positive

thermoelement and a Cu-Al alloy (Alumel™) as the negative thermoelement. It may be used in

inert environments, but not in sulfurous or reducing atmospheres, or environments that promote

corrosion. Sensitivity at 20K: 4.1 µV/K. Recommended useful temperature range is 3 K to 575 K.

Type T (Copper-Constantan)

Type T is a thermocouple pair consisting of Cu (Copper) as the positive thermoelement and a Cu-

Ni alloy (Constantan) as the negative element. It may be used in a vacuum as well as oxidizing,

reducing or inert environments down to 90 K. At temperatures below 80 K, the thermoelectric

properties of the positive thermoelement depend largely on the impurity of iron. The high thermal

conductivity of the copper element makes this thermocouple the least usable for cryogenic

applications. Sensitivity at 20 K: 4.6 µV/K.

Chromel™-CuFe (0.15%)

The Chromel™-Copper/Iron thermocouple consists of a Ni-Cr alloy (Chromel™) as the positive

thermoelement and a Copper/0.15% Iron alloy as the negative thermoelement. Sensitivity at

4.2K: >11 µV/K. Less expensive than Gold-Chromel™ thermocouples and physically stronger.

Recommended useful temperature range is 4 K to 300 K.