Lake Shore Model 321 Autotuning Temperature Controller User’s Manual

1-8

Introduction

1.6 ELECTROSTATIC

DISCHARGE

Electrostatic Discharge (ESD) may damage electronic parts, assemblies, and equipment. ESD is a

transfer of electrostatic charge between bodies at different electrostatic potentials caused by direct

contact or induced by an electrostatic field. The low-energy source that most commonly destroys

Electrostatic Discharge Sensitive (ESDS) devices is the human body, which generates and retains

static electricity. Simply walking across a carpet in low humidity may generate up to 35,000 volts of

static electricity.

Current technology trends toward greater complexity, increased packaging density, and thinner

dielectrics between active elements, which results in electronic devices with even more ESD sensitivity.

Some electronic parts are more ESDS than others. ESD levels of only a few hundred volts may

damage electronic components such as semiconductors, thick and thin film resistors, and piezoelectric

crystals during testing, handling, repair, or assembly. Discharge voltages below 4000 volts cannot be

seen, felt, or heard.

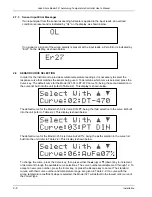

1.6.1 Identification of Electrostatic Discharge Sensitive Components

Below are various industry symbols used to label components as ESDS:

1.6.2 Handling Electrostatic Discharge Sensitive Components

Observe all precautions necessary to prevent damage to ESDS components before attempting

installation. Bring the device and everything that contacts it to ground potential by providing a

conductive surface and discharge paths. As a minimum, observe these precautions:

1. Deenergize or disconnect all power and signal sources and loads used with unit.

2. Place unit on a grounded conductive work surface.

3. Ground technician through a conductive wrist strap (or other device) using 1 M

Ω

series resistor to

protect operator.

4. Ground any tools, such as soldering equipment, that will contact unit. Contact with operator's

hands provides a sufficient ground for tools that are otherwise electrically isolated.

5. Place ESDS devices and assemblies removed from a unit on a conductive work surface or in a

conductive container. An operator inserting or removing a device or assembly from a container

must maintain contact with a conductive portion of the container. Use only plastic bags approved

for storage of ESD material.

6. Do not handle ESDS devices unnecessarily or remove from the packages until actually used or

tested.